Eight Disciplines of Problem Solving (8D)

– Eight Disciplines of Problem Solving –

⇓ Introduction to 8D

⇓ What is 8D

⇓ Why Apply 8D

⇓ When to Apply 8D

⇓ How to Apply 8D

Introduction to Eight Disciplines of Problem Solving (8D)

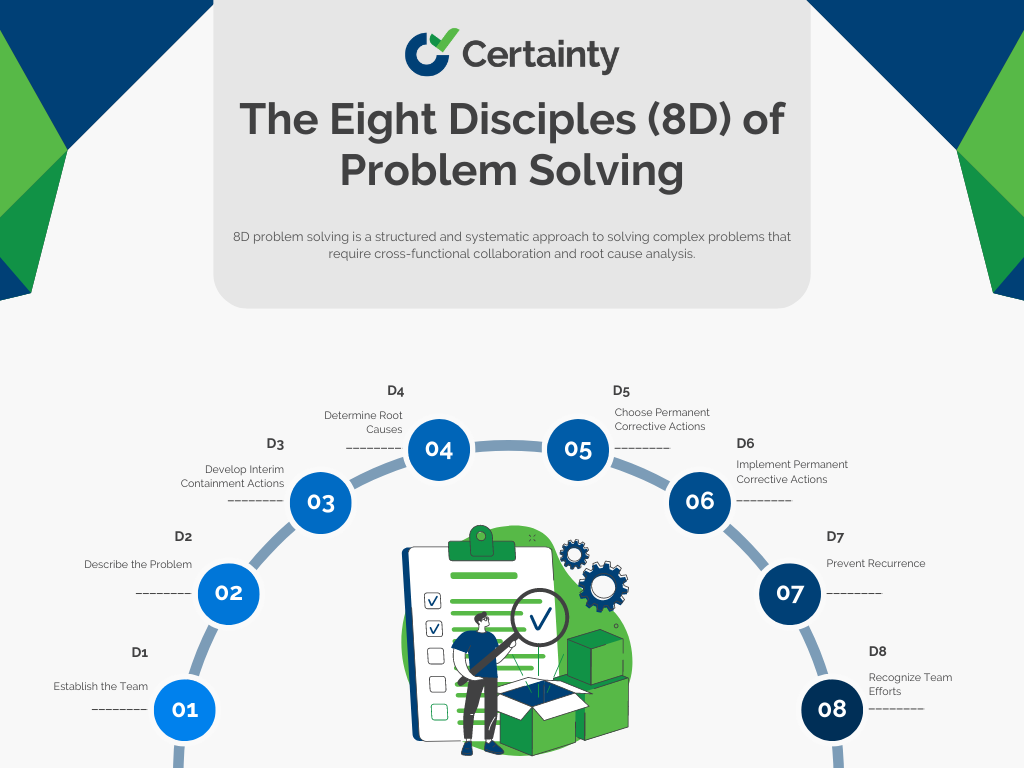

The Eight Disciplines of Problem Solving (8D) is a problem solving methodology designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D has become very popular among manufacturers because it is effective and reasonably easy to teach. Below you’ll find the benefits of an 8D, when it is appropriate to perform and how it is performed.

What is Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The strength of the 8D process lies in its structure, discipline and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from a systemic failure.

8D has grown to be one of the most popular problem solving methodologies used for Manufacturing, Assembly and Services around the globe. Read on to learn about the reasons why the Eight Disciplines of Problem Solving may be a good fit for your company.

Why Apply Eight Disciplines of Problem Solving (8D)

The 8D methodology is so popular in part because it offers your engineering team a consistent, easy-to-learn and thorough approach to solving whatever problems might arise at various stages in your production process. When properly applied, you can expect the following benefits:

- Improved team oriented problem solving skills rather than reliance on the individual

- Increased familiarity with a structure for problem solving

- Creation and expansion of a database of past failures and lessons learned to prevent problems in the future

- Better understanding of how to use basic statistical tools required for problem solving

- Improved effectiveness and efficiency at problem solving

- A practical understanding of Root Cause Analysis (RCA)

- Problem solving effort may be adopted into the processes and methods of the organization

- Improved skills for implementing corrective action

- Better ability to identify necessary systemic changes and subsequent inputs for change

- More candid and open communication in problem solving discussion, increasing effectiveness

- An improvement in management’s understanding of problems and problem resolution

8D was created to represent the best practices in problem solving. When performed correctly, this methodology not only improves the Quality and Reliability of your products but also prepares your engineering team for future problems.

When to Apply Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is typically required when:

- Safety or Regulatory issues has been discovered

- Customer complaints are received

- Warranty Concerns have indicated greater-than-expected failure rates

- Internal rejects, waste, scrap, poor performance or test failures are present at unacceptable levels

How to Apply Eight Disciplines of Problem Solving (8D)

The 8D process alternates inductive and deductive problem solving tools to relentlessly move forward toward a solution. The Quality-One approach uses a core team of three individuals for inductive activities with data driven tools and then a larger Subject Matter Expert (SME) group for the deductive activities through brainstorming, data-gathering and experimentation.

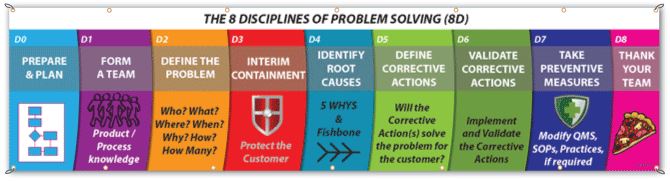

D0: Prepare and Plan for the 8D

Proper planning will always translate to a better start. Thus, before 8D analysis begins, it is always a good idea to ask an expert first for their impressions. After receiving feedback, the following criterion should be applied prior to forming a team:

Collect information on the symptoms

Use a Symptoms Checklist to ask the correct questions

Identify the need for an Emergency Response Action (ERA), which protects the customer from further exposure to the undesired symptoms

D1: Form a Team

A Cross Functional Team (CFT) is made up of members from many disciplines. Quality-One takes this principle one step further by having two levels of CFT:

- The Core Team Structure should involve three people on the respective subjects: product, process and data

- Additional Subject Matter Experts are brought in at various times to assist with brainstorming, data collection and analysis

Teams require proper preparation. Setting the ground rules is paramount. Implementation of disciplines like checklists, forms and techniques will ensure steady progress. 8D must always have two key members: a Leader and a Champion / Sponsor:

- The Leader is the person who knows the 8D process and can lead the team through it (although not always the most knowledgeable about the problem being studied)

- The Champion or Sponsor is the one person who can affect change by agreeing with the findings and can provide final approval on such changes

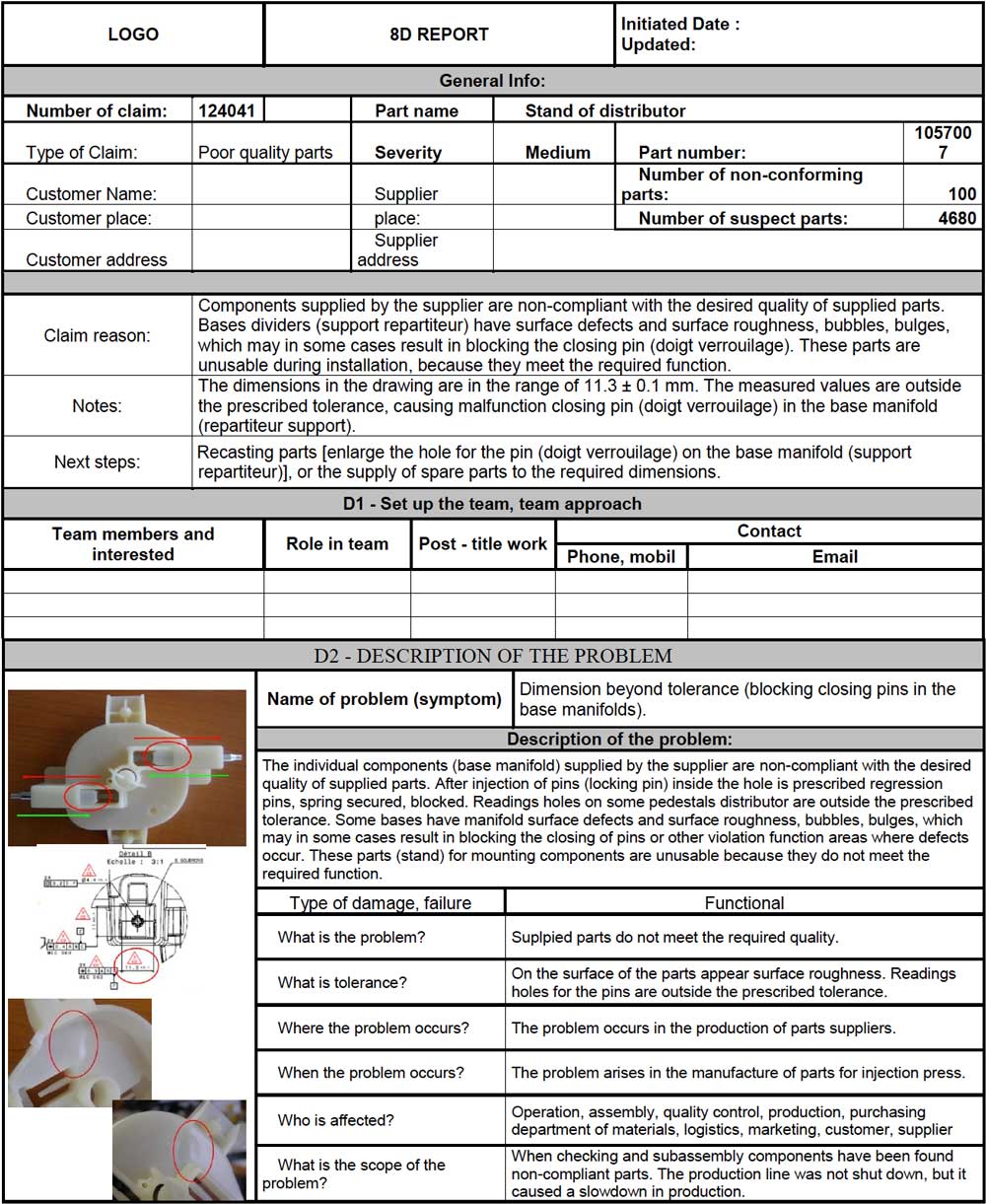

D2: Describe the Problem

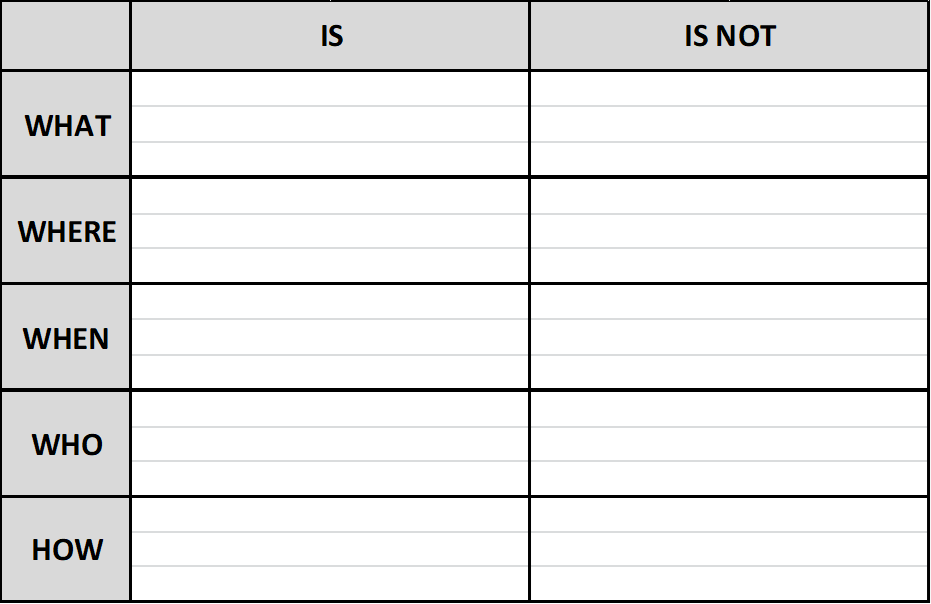

The 8D method’s initial focus is to properly describe the problem utilizing the known data and placing it into specific categories for future comparisons. The “Is” data supports the facts whereas the “Is Not” data does not. As the “Is Not” data is collected, many possible reasons for failure are able to be eliminated. This approach utilizes the following tools:

- Problem Statement

- Affinity Diagram (Deductive tool)

- Fishbone/Ishikawa Diagram (Deductive tool)

- Problem Description

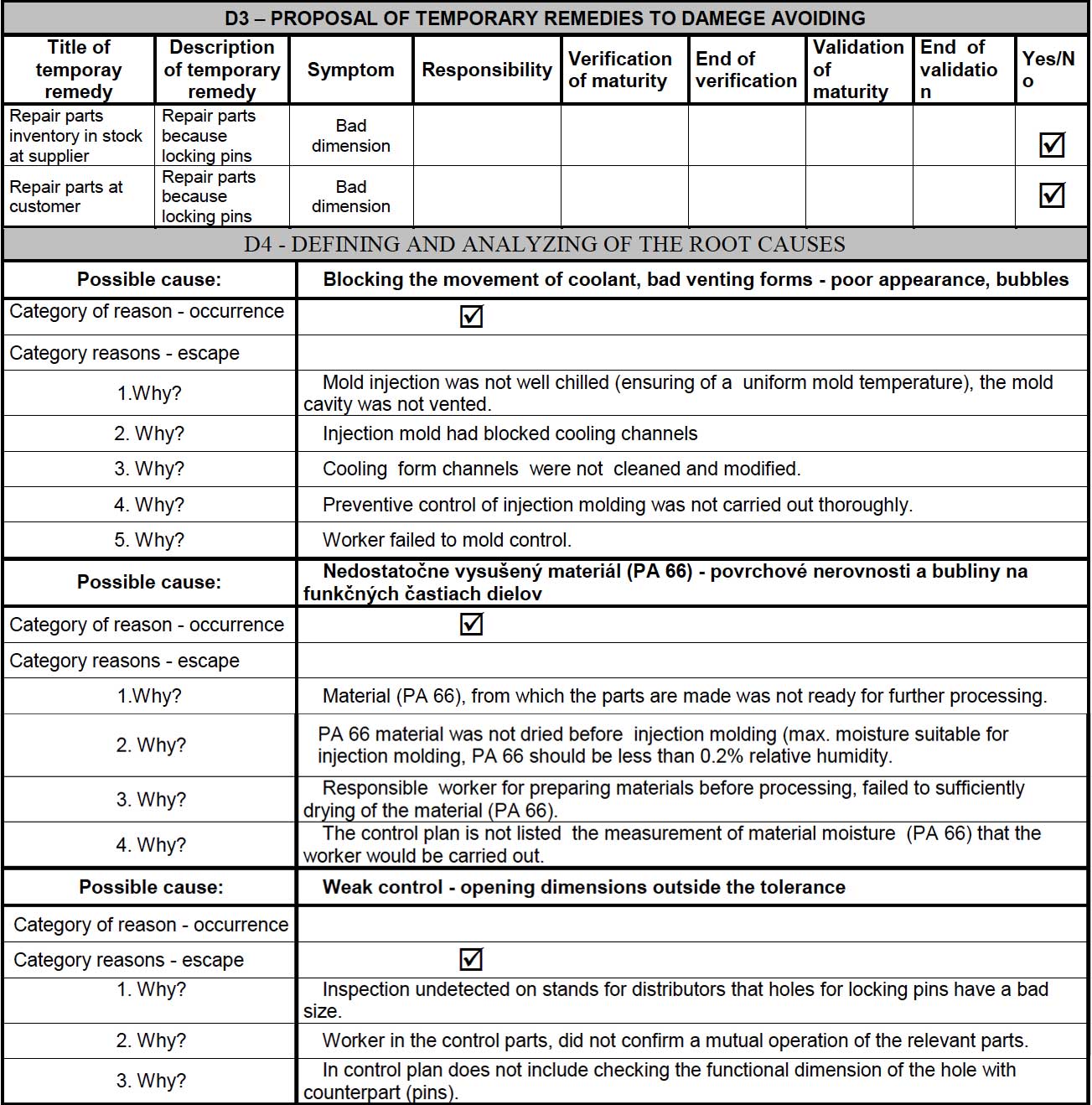

D3: Interim Containment Action

In the interim, before the permanent corrective action has been determined, an action to protect the customer can be taken. The Interim Containment Action (ICA) is temporary and is typically removed after the Permanent Correct Action (PCA) is taken.

- Verification of effectiveness of the ICA is always recommended to prevent any additional customer dissatisfaction calls

D4: Root Cause Analysis (RCA) and Escape Point

The root cause must be identified to take permanent action to eliminate it. The root cause definition requires that it can be turned on or off, at will. Activities in D4 include:

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- Verification of the Root Cause through data collection

- Review Process Flow Diagram for location of the root cause

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

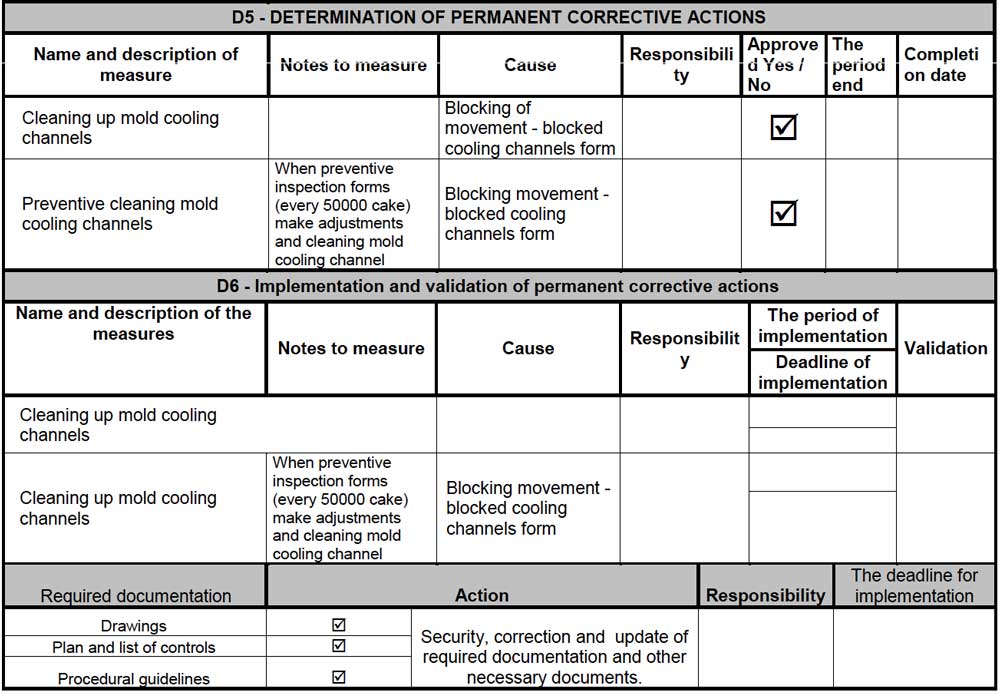

D5: Permanent Corrective Action (PCA)

The PCA is directed toward the root cause and removes / changes the conditions of the product or process that was responsible for the problem. Activities in D5 include:

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

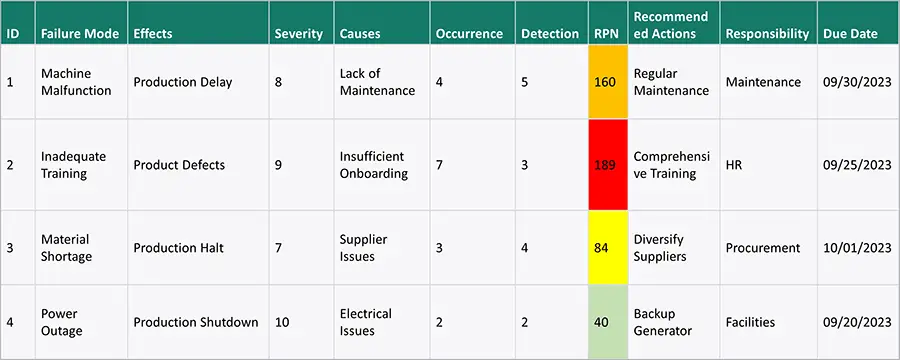

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verification of Effectiveness for both the PCA and the Escape Point are required

D6: Implement and Validate the Permanent Corrective Action

To successfully implement a permanent change, proper planning is essential. A project plan should encompass: communication, steps to complete, measurement of success and lessons learned. Activities in D6 include:

- Develop Project Plan for Implementation

- Communicate the plan to all stakeholders

- Validation of improvements using measurement

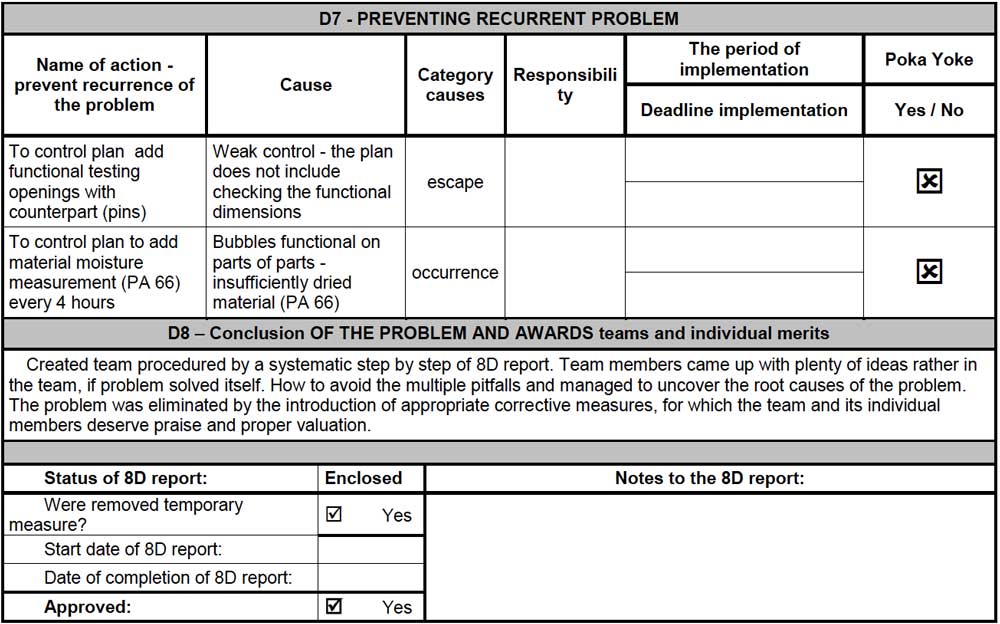

D7: Prevent Recurrence

D7 affords the opportunity to preserve and share the knowledge, preventing problems on similar products, processes, locations or families. Updating documents and procedures / work instructions are expected at this step to improve future use. Activities in D7 include:

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

D8: Closure and Team Celebration

Teams require feedback to allow for satisfactory closure. Recognizing both team and individual efforts and allowing the team to see the previous and new state solidifies the value of the 8D process. Activities in D8 include:

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

8D and Root Cause Analysis (RCA)

The 8D process has Root Cause Analysis (RCA) imbedded within it. All problem solving techniques include RCA within their structure. The steps and techniques within 8D which correspond to Root Cause Analysis are as follows:

- Problem Symptom is quantified and converted to “Object and Defect”

- Problem Symptom is converted to Problem Statement using Repeated Whys

- Possible and Potential Causes are collected using deductive tools (i.e. Fishbone or Affinity Diagram)

- Problem Statement is converted into Problem Description using Is / Is Not

- Problem Description reduces the number of items on the deductive tool (from step 3)

- Comparative Analysis between the Is and Is Not items (note changes and time)

- Root Cause theories are developed from remaining possible causes on deductive tool and coupled with changes from Is / Is Not

- Compare theories with current data and develop experiments for Root Cause Verification

- Test and confirm the Root Causes

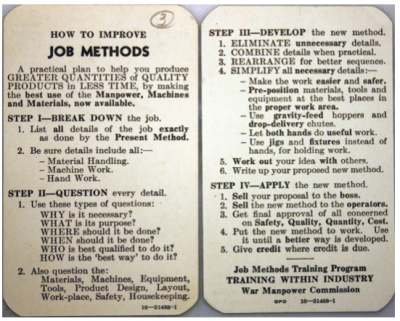

Example: Multiple Why Technique

The Multiple / Repeated Why (Similar to 5 Why) is an inductive tool, which means facts are required to proceed to a more detailed level. The steps required to determine problem statement are:

- Problem Symptom is defined as an Object and Defect i.e. “Passenger Injury”

- Why? In every case “SUV’s Roll Over”

- Why? In every case, it was preceded by a “Blown Tire”

- Why? Many explanations may be applied, therefore the team cannot continue with another repeated why past “Blown Tire”

- Therefore, the Problem Statement is “Blown Tire”

- Why? Low (Air) Pressure, Tire Defect (Degradation of an Interface) and High (Ambient) Temperature

- Counter measures assigned to low pressure and tire defect

This example uses only 4 of the 5 Whys to determine the root causes without going further into the systemic reasons that supported the failure. The Repeated Why is one way to depict this failure chain. Fault Tree Analysis (FTA) could also be used.

Learn More About Eight Disciplines of Problem Solving (8D)

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 8D Consulting , 8D Training or 8D Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

- Don't have an account? Register

- Lost your password? Click here

- Already have an account? Log in

- Product overview

- All features

- App integrations

CAPABILITIES

- project icon Project management

- Project views

- Custom fields

- Status updates

- goal icon Goals and reporting

- Reporting dashboards

- workflow icon Workflows and automation

- portfolio icon Resource management

- Time tracking

- my-task icon Admin and security

- Admin console

- asana-intelligence icon Asana AI

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Campaign management

- Creative production

- Content calendars

- Marketing strategic planning

- Resource planning

- Project intake

- Product launches

- Employee onboarding

- View all uses arrow-right icon

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Work management resources Discover best practices, watch webinars, get insights

- What's new Learn about the latest and greatest from Asana

- Customer stories See how the world's best organizations drive work innovation with Asana

- Help Center Get lots of tips, tricks, and advice to get the most from Asana

- Asana Academy Sign up for interactive courses and webinars to learn Asana

- Developers Learn more about building apps on the Asana platform

- Community programs Connect with and learn from Asana customers around the world

- Events Find out about upcoming events near you

- Partners Learn more about our partner programs

- Support Need help? Contact the Asana support team

- Asana for nonprofits Get more information on our nonprofit discount program, and apply.

Featured Reads

- Project management |

- What is 8D? A template for efficient pr ...

What is 8D? A template for efficient problem-solving

How you respond when problems arise is one of the most defining qualities of a manager. Luckily, there are tools you can use to master problem-solving. The 8D method of problem-solving combines teamwork and basic statistics to help you reach a logical solution and prevent new issues from arising.

You’ve spent months overseeing the development of your company's newest project. From initiation, planning, and execution, you’re confident this may be your best work yet.

Until the feedback starts rolling in.

There’s no sugar-coating it—things don’t always go as planned. But production or process issues are hardly a signal to throw in the towel. Instead, focus on honing your problem-solving skills to find a solution that keeps it from happening again.

The 8D method of problem solving emphasizes the importance of teamwork to not only solve your process woes but prevent new ones from occurring. In this guide, we’ll break down what 8D is, how to use this methodology, and the benefits it can give to you and your team. Plus, get an 8D template to make solving your issue easier.

What is 8D?

The eight disciplines (8D) method is a problem-solving approach that identifies, corrects, and eliminates recurring problems. By determining the root causes of a problem, managers can use this method to establish a permanent corrective action and prevent recurring issues.

How do you use the 8D method?

The 8D method is a proven strategy for avoiding long-term damage from recurring problems. If you’re noticing issues in your workflow or processes, then it’s a good time to give this problem-solving method a try.

To complete an 8D analysis, follow “the eight disciplines” to construct a statistical analysis of the problem and determine the best solution.

The eight disciplines of problem-solving

8D stands for the eight disciplines you will use to establish an 8D report. As you may notice, this outline starts with zero, which makes nine total disciplines. The “zero stage” was developed later as an initial planning stage.

To illustrate these steps, imagine your organization experienced a decline in team innovation and productivity this past year. Your stakeholders have noticed and want to see changes implemented within the next six months. Below, we’ll use the 8D process to uncover a morale-boosting solution.

![definition 8d problem solving [inline illustration] D8 problem solving approach (infographic)](https://assets.asana.biz/transform/6ab7c188-3258-4d2e-afe6-9a4a084cc09f/inline-productivity-8d-template-1-2x?io=transform:fill,width:2560&format=webp)

D0: Prepare and plan

Before starting the problem-solving process, evaluate the problem you want to solve. Understanding the background of the problem will help you identify the root cause in later steps.

Collect information about how the problem has affected a process or product and what the most severe consequences may be. Planning can include:

Gathering data

Determining the prerequisites for solving the problem

Collecting feedback from others involved

![definition 8d problem solving [inline illustration] D0 Planning (example)](https://assets.asana.biz/transform/abc3621d-e1ae-47ff-b731-0ee38cff99e9/inline-productivity-8d-template-2-2x?io=transform:fill,width:2560&format=webp)

If we look back at our example, you may want to figure out whether this decline in morale is organization-wide or only applies to a few departments. Consider interviewing a few employees from different departments and levels of management to gain some perspective. Next, determine what knowledge and skills you will need to solve this lapse in productivity.

D1: Form your team

Create a cross-functional team made up of people who have knowledge of the various products and workflows involved. These team members should have the skills needed to solve the problem and put corrective actions in place.

Steps in this discipline may include:

Appointing a team leader

Developing and implementing team guidelines

Determining team goals and priorities

Assigning individual roles

Arranging team-building activities

![definition 8d problem solving [inline illustration] D1 Team members (example)](https://assets.asana.biz/transform/51986017-5150-4dd4-940c-252cd0eb8ba5/inline-productivity-8d-template-3-2x?io=transform:fill,width:2560&format=webp)

From our example, a solid team would consist of people with first-hand experience with the issues—like representatives from all departments and key people close to workshop-level work. You may also want to pull someone in from your HR department to help design and implement a solution. Most importantly, make sure the people you choose want to be involved and contribute to the solution.

D2: Identify the problem

You may have a good understanding of your problem by now, but this phase aims to break it down into clear and quantifiable terms by identifying the five W’s a and two H’s (5W2H):

Who first reported the problem?

What is the problem about?

When did it occur and how often?

Where did it occur (relating to the sector, supplier, machine, or production line involved)?

Why is solving the problem important?

How was the problem first detected?

How many parts/units/customers are affected?

![definition 8d problem solving [inline illustration] D2 Problem statement & description (example)](https://assets.asana.biz/transform/9825ecd6-2bd3-4559-a68c-b1ae8aca2e52/inline-productivity-8d-template-4-2x?io=transform:fill,width:2560&format=webp)

Use your team’s insights to answer these questions. From our example, your team may conclude that:

Employees feel overwhelmed with their current workload.

There is no real structure or opportunity to share new ideas.

Managers have had no training for meetings or innovation settings.

Disgruntled employees know they can achieve more—and want to achieve more—even if they seem disengaged.

Once you answer these questions, record an official problem statement to describe the issue. If possible, include photos, videos, and diagrams to ensure all parties have a clear understanding of the problem. It may also help to create a flowchart of the process that includes various steps related to the problem description.

D3: Develop an interim containment plan

Much like we can expect speedy first aid after an accident, your team should take immediate actions to ensure you contain the problem—especially if the problem is related to customer safety.

An interim containment plan will provide a temporary solution to isolate the problem from customers and clients while your team works to develop a permanent corrective action. This band-aid will help keep your customers informed and safe—and your reputation intact.

![definition 8d problem solving [inline illustration] D3 Interim containment action (example)](https://assets.asana.biz/transform/d6279c36-ccc6-4de3-89d2-f221632a1059/inline-productivity-8d-template-5-2x?io=transform:fill,width:2560&format=webp)

Because your findings revealed workers were overworked and managers lacked training, your team suggests scheduling a few mandatory training sessions for leaders of each department covering time and stress management and combating burnout . You may also want to have a presentation outlining the topics of this training to get key managers and stakeholders interested and primed for positive upcoming changes.

D4: Verify root causes and escape points

Refer back to your findings and consult with your team about how the problem may have occurred. The root cause analysis involves mapping each potential root cause against the problem statement and its related test data. Make sure to test all potential causes—fuzzy brainstorming and sloppy analyses may cause you to overlook vital information.

![definition 8d problem solving [inline illustration] D4 Root cause & escape points (example)](https://assets.asana.biz/transform/301717c6-0434-4c88-addf-d500dc23ae87/inline-productivity-8d-template-6-2x?io=transform:fill,width:2560&format=webp)

In our example, focus on the “why” portion of the 5W2H. You and your team identify six root causes:

Managers have never had any training

There is a lack of trust and psychological safety

Employees don’t understand the objectives and goals

Communication is poor

Time management is poor

Employees lack confidence

In addition to identifying the root causes, try to pinpoint where you first detected the problem in the process, and why it went unnoticed. This is called the escape point, and there may be more than one.

D5: Choose permanent corrective actions

Work with your team to determine the most likely solution to remove the root cause of the problem and address the issues with the escape points. Quantitatively confirm that the selected permanent corrective action(s) (PCA) will resolve the problem for the customer.

Steps to choosing a PCA may include:

Determining if you require further expertise

Ensuring the 5W2Hs are defined correctly

Carrying out a decision analysis and risk assessment

Considering alternative measures

Collecting evidence to prove the PCA will be effective

![definition 8d problem solving [inline illustration] D5 Permanent corrective action (example)](https://assets.asana.biz/transform/53509966-18dd-4bb4-88a1-c7ca940fde3f/inline-productivity-8d-template-7-2x?io=transform:fill,width:2560&format=webp)

Your team decides to roll out the training used in the interim plan to all employees, with monthly company-wide workshops on improving well-being. You also plan to implement meetings, innovation sessions, and team-coaching training for managers. Lastly, you suggest adopting software to improve communication and collaboration.

D6: Implement your corrective actions

Once all parties have agreed on a solution, the next step is to create an action plan to remove the root causes and escape points. Once the solution is in effect, you can remove your interim containment actions.

After seeing success with the training in the interim phase, your stakeholders approve all of your team’s proposed PCAs. Your representative from HR also plans to implement periodic employee wellness checks to track employee morale .

![definition 8d problem solving [inline illustration] D6 PCA implementation plan (example)](https://assets.asana.biz/transform/ca68af4a-afa7-4be4-93cb-8a8321eb5172/inline-productivity-8d-template-8-2x?io=transform:fill,width:2560&format=webp)

To ensure your corrective action was a success, monitor the results, customer, or employee feedback over a long period of time and take note of any negative effects. Setting up “controls” like employee wellness checks will help you validate whether your solution is working or more needs to be done.

D7: Take preventive measures

One of the main benefits of using the 8D method is the improved ability to identify necessary systematic changes to prevent future issues from occurring. Look for ways to improve your management systems, operating methods, and procedures to not only eliminate your current problem, but stop similar problems from developing later on.

![definition 8d problem solving [inline illustration] D7 Preventive measure (example)](https://assets.asana.biz/transform/cdd7b133-fb80-4db7-8935-1285a6b62b69/inline-productivity-8d-template-9-2x?io=transform:fill,width:2560&format=webp)

Based on our example, the training your team suggested is now adopted in the new manager onboarding curriculum. Every manager now has a “meeting system” that all meetings must be guided by, and workloads and projects are managed as a team within your new collaboration software . Innovation is improving, and morale is at an all-time high!

D8: Celebrate with your team

The 8D method of problem-solving is impossible to accomplish without dedicated team members and first-class collaboration. Once notes, lessons, research, and test data are documented and saved, congratulate your teammates on a job well done! Make an effort to recognize each individual for their contribution to uncovering a successful solution.

![definition 8d problem solving [inline illustration] 8D Team congratulations & reward (example)](https://assets.asana.biz/transform/d2055965-bf3d-4bf4-a1ea-a0a7c4bf8a32/inline-productivity-8d-template-10-2x?io=transform:fill,width:2560&format=webp)

8D report template and example

Check out our 8D report template below to help you record your findings as you navigate through the eight disciplines of problem solving. This is a formal report that can be used as a means of communication within companies, which makes for transparent problem-solving that you can apply to the entire production or process chain.

Benefits of using the 8D method

The 8D method is one of the most popular problem-solving strategies for good reason. Its strength lies in teamwork and fact-based analyses to create a culture of continuous improvement —making it one of the most effective tools for quality managers. The benefits of using the 8D method include:

Improved team-oriented problem-solving skills rather than relying on an individual to provide a solution

Increased familiarity with a problem-solving structure

A better understanding of how to use basic statistical tools for problem-solving

Open and honest communication in problem-solving discussions

Prevent future problems from occurring by identifying system weaknesses and solutions

Improved effectiveness and efficiency at problem-solving

Better collaboration = better problem solving

No matter how good a manager you are, production and process issues are inevitable. It’s how you solve them that separates the good from the great. The 8D method of problem solving allows you to not only solve the problem at hand but improve team collaboration, improve processes, and prevent future issues from arising.

Try Asana’s project management tool to break communication barriers and keep your team on track.

Related resources

Data-driven decision making: A step-by-step guide

How Asana uses work management for employee onboarding

4 ways to establish roles and responsibilities for team success

6 ways to develop adaptability in the workplace and embrace change

Discover your potential savings with our ROI Calculator

8D Management (8 Disciplines Management)

8D Management & The 8D of Problem Solving

Problems are a part of life and a business is no exception. Even with the best of intentions and systems, some errors can creep in and be hard to detect. It may be nothing serious or can have serious repercussions such as reputation damage, heavy fines, product recall, property loss, and so on. It becomes essential to identify the problem, its consequences on the one hand, and causes on the other to be able to not only resolve it for now but also ensure prevention of its recurrence. One of the methodologies, popular amongst engineers and professionals mainly in the automotive industry but now applied across several industries is the eight disciplines (8D) model. It helps to identify, correct, and eliminate recurring problems, affecting improvement in product and process.

Related Assets

Whenever organizations tackle problems and generate solutions based out of root cause analysis, they tend to generate a lot of…

Key Highlights: 8D is an extremely effective, proven problem-solving framework, especially in the manufacturing and automotive sector. However, to truly…

From a quality management standpoint, a problem may be reported in an organization from one of the following processes: Complaints…

What is 8D?

The 8D is a systematic, holistic and proven methodology designed to identify the root cause of a problem, plan a quick fix, and implement corrective actions and preventive actions to avoid their recurrence. If your product is defective or not meeting your customer requirements, then 8D is an excellent first step to improve Quality and Reliability.

One of the core parts of introducing 8D problem solving, greatly accepted by most disciplines of industries, and having huge effectiveness levels in improving product and process quality, would be 8D (Eight Disciplines). Key steps in the 8D methodology are forming a team, defining the problem, identifying and implementing interim containment, identifying the root causes, implementing and verifying permanent corrective actions, and avoiding future recurrence of problems. The 8D process for root cause analysis concludes by highlighting that the team members not only play a vital role but also recognizes them, hence reinforcing that this approach is a collaborative one. 8D has become very popular among manufacturers, assembly, and services around the globe because it is effective and comparatively easy to teach.

Introduction to 8d Problem Solving

The 8D approach to problem-solving, also known as the 8D methodology, is a systematic and comprehensive method used to address and resolve complex issues, particularly in manufacturing and other industries.

This 8D troubleshooting methodology involves a structured process designed to identify, correct, and prevent issues, ensuring that similar problems do not occur in the future.

By following the 8D process steps, teams can effectively perform root cause analysis and implement corrective actions.

The 8D structured problem-solving process is highly valued for its ability to provide a clear framework for identifying and eliminating the root cause of a problem, thereby enhancing overall operational efficiency.

Why to Apply 8D Problem Solving Methodology?

The 8D methodology, developed to represent the best practices in problem solving, provides the engineering teams with an effective and efficient team-oriented problem solving skill, a better understanding of Root Cause Analysis (RCA) and how to use basic statistical tools required for problem solving. 8D helps the management understand and resolve problems better, identify necessary systemic changes and inputs for change , and facilitate a more candid and open communication in problem solving discussions.

8D improves the Quality and Reliability of your products, and if performed correctly, prepares the engineering team for future problems.

When to Apply 8D Problem Solving Process?

The 8D problem solving process is used to solve major, critical, chronic, and recurring problems. The 8D is typically required during safety or regulatory issues, customer complaints , warranty concerns, poor performance or test failures, internal rejects, and to minimize waste and scrap.

How to Use Root Cause Analysis to Transform Your Safety Program

8d problem solving approach.

The 8D is a systematic process for the introduction and improvement of quality, and elimination of problems. Here we will show you the step by step approach of the problem solving tools that can make you proficient at identifying causes of problems, defining problems, and errors. Additionally, it helps identify root causes and take actions to solve and prevent identified problems in processes. So, let’s take a peep inside:

D0: Planning and preparing for the 8D

Proper planning and preparation are always a good start before taking any action. So, you need to consider the following before forming a team:

- Problem description

- Timeframe for the resolution

- The number of resources to accomplish this

D1: Team establishment

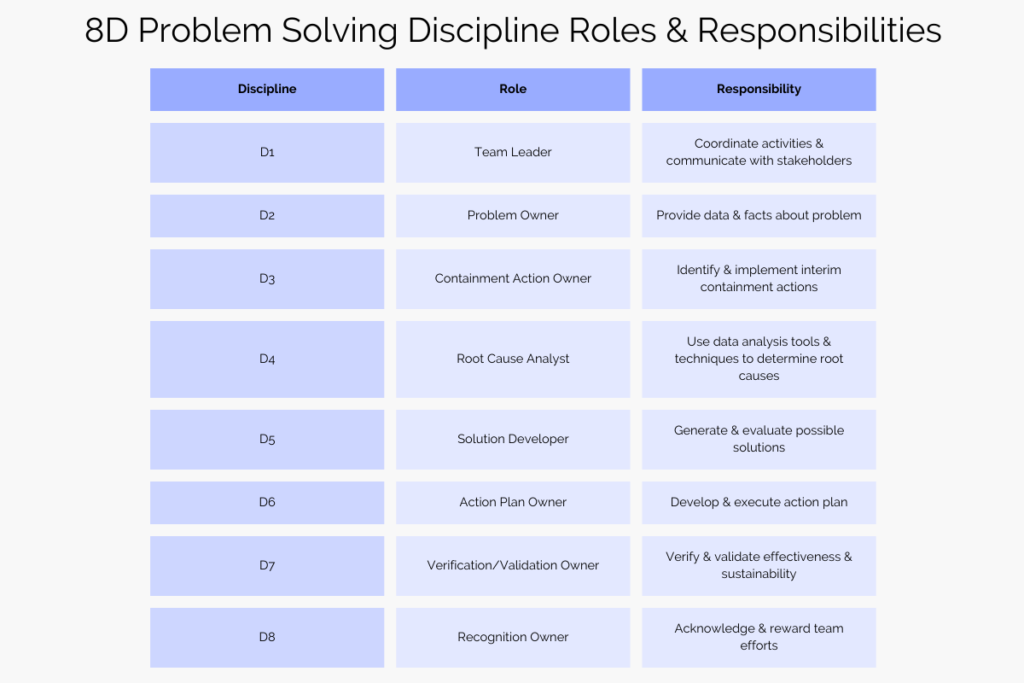

Create a team with people who varied backgrounds and experiences which will lead to the best quality inputs and a complete solution. For the team to function smoothly, define clear roles, and responsibilities for your people, and have a team leader.

D2: Problem description

The 8D method’s primary focus is to describe the problem appropriately and objectively such that it captures all the vital information. During this analysis, repeated 5W1H (why, what, who, where, when, and how) are required to be asked to develop a clear description.

D3: Problem containment plan

A temporary problem containment plan is sometimes needed to minimize the impact of the problem until you develop permanent solutions. On developing the plan based on the hypothetical cases, the resources for addressing the main problem can be released. At times, new processes may be required to work around the problem until you have a permanent fix.

D4: Root Cause Analysis (RCA)

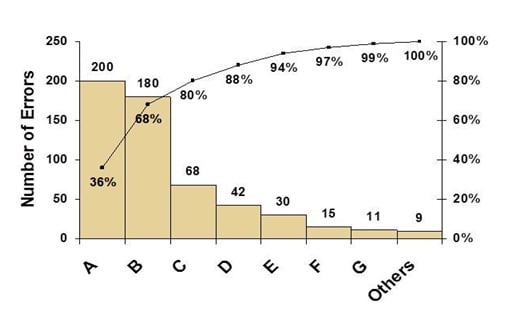

With the problem temporarily contained, you can now turn to identify all of the root causes of the nonconformance . There are several tools to identify the actual root cause of an issue including the 5W1H to understand the problem in-depth, Fishbone diagrams to visually categorize causes, and Pareto charts to identify the vital causes.

D5: Permanent Corrective Action

Once the root cause of the problem is determined, the team can start brainstorming permanent corrections to identify what the best long-term solution will be. Brainstorming sessions combined with tools such as affinity diagrams help organize ideas based on their relationships and determine the best course of action.

D6: Implement and Validate the Permanent Corrective Action

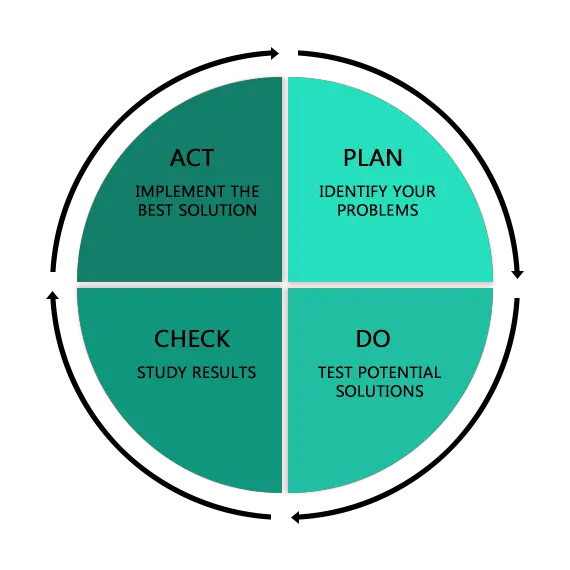

Once the solution is identified, the management needs to implement and verify the corrective action using the PDCA (plan-do-check-act) approach for small-scale testing before large-scale rollout. Thus, the outcomes and corrective actions are tracked to ensure expected results. To successfully implement a permanent change, a project plan should incorporate:

- Development of the project plan for implementation

- Communicating the plan to all stakeholders

- Validating improvements using measurement

D7: Prevent Recurrence

A complete solution of problems means preventing them from occurring. Besides, preventative measures should also be implemented for corrective actions in the 8D methodology. This requires reviewing management processes, operating procedures, and training manuals to ensure that best practices are followed.

At this stage, organizations should consider actions including updating process audit questions and regularly verifying them based on corrective actions to reduce risk in other processes, presenting poka-yoke or error-proofing devices to big-risk processes, and conducting red rabbit tests to see how long it takes poka-yoke devices to detect defective product.

D8: Verification and Team Celebration

Once the problem is solved, the ultimate step is to congratulate the team. It’s important to recognize their efforts and share their success across the organization because teams require feedback to allow for satisfactory closure. This facilitates motivation and employee engagement while helping you improve quality control, execute process improvements, and aid change management as you grow.

Create a team with people who are having varied backgrounds and experiences which will lead to the best quality inputs and a complete solution. For the team to function smoothly, define clear roles, and responsibilities for your people, and have a team leader.

A complete solution of problems means preventing them from occurring initially. Besides, preventative measures should also be implemented for corrective actions in the 8D methodology. This requires reviewing management processes, operating procedures, and training manuals to ensure that best practices are followed.

8D Root Cause Analysis (RCA) and 8D Corrective Action Process

The 8D Root Cause Analysis, as well as the 8D Corrective Action process, is a widely systematic approach in quality management , especially concerning 8D in quality control. This method includes eight comprehensive steps that are devised to problem solving by dealing with root causes of the problems comprehensively. The steps of the 8D process start with the formation of a team, a clear definition of the problem, and move on to interim containment actions. This is then followed by detailed root-cause analysis using the 8D RCA process, development and verification of permanent corrective actions, implementation, and recurrence preventing efforts. Encouraging details in the analysis: the 8D methodology steps encompass collaborative efforts and documentation that ensure durable solutions and continuous improvement in organizational processes. Root Cause Analysis (RCA) is embedded within the 8D process and includes the following steps and techniques:

Problem Symptom is measured and transformed to “Object and Defect”

Problem Symptom is reformed to Problem Statement using the 5W1H process

Potential Causes are gathered using the tools like Fishbone or Affinity Diagram

Problem Statement should fit using both the “is” and the “isn’t” sections of the question

Root Cause concepts are developed from remaining possible causes on the tool and related changes from is/is not

Compare theories with recent data and develop experiments for Root Cause Verification

Test and confirm the Root Causes

Customer Success

3 Women Leaders Making a Powerful Impact in Global Quality and Safety Management

How to use the 8d approach.

8D portrays 8 steps of a structured approach to solve difficult, recurring, or critical problems by providing transparency, driving a team approach, and increasing the chances of solving the problem.

Proper plan for solving the problem and identify the prerequisites.

Team creation

Gather a cross-functional team with product/process knowledge.

Problem description and definition

Use the data and information to specify the problem by identifying in quantifiable terms the who, what, where, when, why, how, and how many (the 5W1H) for the problem.

Problem Containment Plan development

Develop and implement interim actions to eliminate the problem from any customer in the future.

Specify and assess Root Causes

Identify and review all relevant causes and sources of variation that analyze why the problem has occurred and figure out why the problem was not noticed at first using 5W1H or diagrams.

Verify Permanent Solutions

After collecting data confirm that the possible solutions will actually resolve the problem.

Implement and Validate Corrective Actions

Discuss and review results and develop plans to implement the best solutions or countermeasures.

Preventive measures

Transform the operation systems, management systems, procedures, and practices to avoid the recurrence of similar problems.

Compliment your team

Recognize the collective efforts of your team and formally thank them for their involvement.

8D Problem Solving Tools and Techniques

The 8D problem solving methodology is the set of tools and methods aiming for complex quality issues. 8D problem solving techniques are basically comprised of a fishbone diagram, 5 Whys analysis, Pareto charts, process flowcharts, and Failure Mode and Effects Analysis (FMEA) to come to terms with the 8D framework. Integration with statistical tools and data analysis in every step of 8D analysis is sure to make the most accurate identification of the root cause.

This approach would ensure that cross-functional teams' participation would not only be present in the brainstorming sessions but also in the 8D problem solving process at the problem solving stage.

Training in 8D Methodology

8D training is an inevitable imperative that makes its deployment in organizations effective. The 8D methodology provides all the necessary details that the teams could apply to the skills and knowledge required at every step in 8D of quality control . Training the workforce on 8D methodology will make them able to apply these aspects when dealing with real-world problems, which will better off the quality and efficiency of the entire organization. It ensures that all these measures and strategies have been inducted to make sure that 8D problem solving approaches are not just tools for problem solution but have been inducted to lay down the base for sustainable quality improvement and prevention practices in the organizational processes.

How to Enhance Quality and Efficiency in 8D Manufacturing?

Understand the Basics of the 8D Approach to Problem Solving

- Familiarize yourself with the principles of the 8D methodology.

- Recognize that the 8D process steps include team formation, problem

Form a Cross-Functional Team

- Assemble a team with diverse skills and perspectives.

- Ensure each member understands their role in the 8D structured problem solving process.

- Use precise language to describe the problem.

- Implement tools like the 5 Whys to aid in the root cause analysis 8d problem solving phase.

Implement Interim Containment Actions

- Take immediate steps to prevent the problem from worsening.

- Document these actions as part of the 8D troubleshooting methodology

Identify and Verify Root Causes

- Conduct a thorough root cause analysis to pinpoint the underlying issues.

- Utilize techniques like fishbone diagrams and Pareto charts in the 8D RCA process.

Develop Permanent Corrective Actions

- Propose solutions that address the root causes identified.

- Ensure these solutions are sustainable and prevent recurrence.

Validate the Corrective Actions

- Test the solutions to ensure they effectively resolve the problem.

- Collect data to confirm the effectiveness of the root cause analysis and the 8Dd corrective action process.

Implement and Monitor Solutions

- Roll out the verified solutions across relevant areas.

- Continuously monitor the impact to ensure long-term success.

Prevent Recurrence

- Update processes and documentation to incorporate the new solutions.

- Train employees on the new procedures to embed them in daily operations.

Recognize and Celebrate Success

- Acknowledge the efforts of the team in solving the problem.

- Use this opportunity to reinforce the importance of the 8D methodology in maintaining quality and efficiency.

Ensuring compliance with FDA regulations is crucial for medical device manufacturers to maintain market access and ensure patient safety. Medical Device Compliance Software plays a pivotal role in helping companies align with these stringent requirements. Here’s how:

Great product, support, and people to work with!

We have rolled-out CQ across our company to automate various elements of QMS requirements such as Document Management, Complaints, Non-conformances, Corrective Action (8D and A3), Supplier Management and Audit Management. We have been using the software for more than 2 years. We are glad to see how well the system is being used across the company. We have several thousand users on the system currently and working to scale the usage further. CQ solution has been configured to meet our needs, works elegantly across languages, across time zones, and business verticals. With integration between CQ and SAP to exchange critical data, the process automation provides a lot of productivity.

CQ configuration team and support have worked hard to ensure that our needs continue to be met. They consistently go above and beyond. We cannot be more pleased with our use of CQ QMS capabilities and would definitely recommend to anyone who is looking for a modern cloud based EQMS solution especially if you want a scalable EQMS solution.

Lia Budiman, Continental Contitech

8D Process Improvement in Different Industries

Automotive Industry

- Application of 8D Methodology: Essential for addressing recurring quality issues and customer complaints.

- Root Cause Analysis 8D Problem Solving: Identifies underlying issues affecting vehicle performance and safety.

- 8D Structured Problem Solving: Used to enhance manufacturing processes and reduce defects.

- 8D Process Steps: Followed rigorously to maintain high safety and quality standards in vehicle production

Aerospace Industry

- 8D Troubleshooting Methodology: Critical for resolving complex technical issues and ensuring compliance with stringent safety regulations.

- 8D RCA Process: Applied to investigate and eliminate root causes of system failures.

- 8D Corrective Action Process: Ensures that preventive measures are implemented to avoid the recurrence of problems.

- 8D Manufacturing: Focuses on precision and reliability in the production of aerospace components.

Electronics Industry

- 8D Approach to Problem Solving: Used to tackle issues related to product design and manufacturing.

- Root Cause Analysis and the 8D Corrective Action Process: Vital for maintaining product quality and reducing warranty claims.

- 8D Process Steps: Helps in identifying and addressing defects in electronic components and assemblies.

- 8D Methodology: Ensures continuous improvement and innovation in electronics manufacturing processes.

Healthcare Industry

- 8D Structured Problem Solving: Applied to improve patient care and operational efficiency in healthcare facilities.

- 8D Problem-Solving Steps: Utilized to address issues related to medical equipment and procedural errors.

- Root Cause Analysis 8D Problem Solving: Enhances patient safety by identifying and eliminating causes of medical errors.

- 8D Troubleshooting Methodology: Ensures that corrective actions are taken to prevent the recurrence of adverse events.

Food and Beverage Industry

- 8D Manufacturing: Ensures product quality and safety throughout the production process.

- 8D Approach to Problem-Solving: Addresses contamination issues and improves production line efficiency.

- Root Cause Analysis and the 8D Corrective Action Process: Essential for maintaining food safety standards.

- 8D Process Steps: Used to investigate and resolve quality issues in food production systematically.

Pharmaceutical Industry

- 8D Methodology: Applied to ensure the consistency and safety of pharmaceutical products.

- 8D RCA Process: Identifies and addresses root causes of deviations in manufacturing processes.

- 8D Corrective Action Process: Implements preventive measures to ensure compliance with regulatory standards.

- 8D Troubleshooting Methodology: Enhances production efficiency and reduces the risk of product recalls.

Consumer Goods Industry

- 8D Structured Problem Solving: Used to resolve product design and manufacturing issues.

- 8D Process Steps: Ensures consistent product quality and customer satisfaction.

- Root Cause Analysis 8D Problem Solving: Identifies and eliminates causes of defects in consumer products.

- 8D Manufacturing: Focuses on improving production processes and reducing waste.

Energy Industry

- 8D Approach to Problem Solving: Applied to address equipment failures and improve operational reliability.

- Root Cause Analysis and the 8D Corrective Action Process: Ensures the continuous improvement of energy production processes.

- 8D Troubleshooting Methodology: Helps resolve complex technical issues in energy plants.

- 8D RCA Process: Identifies and eliminates causes of energy generation and distribution inefficiencies.

8D Process Metrics and KPIs

- Problem Resolution Time: This metric tracks the time taken from problem identification to resolution in the 8D root cause analysis process, ensuring timely corrective actions are implemented to prevent recurrence.

- Recurrence Rate: By measuring how often a similar problem reappears after the 8D corrective action process, this KPI helps assess the effectiveness of the implemented solutions and continuous improvement efforts.

- Root Cause Identification Accuracy: This KPI evaluates the precision and accuracy with which the root causes are identified during the 8D root cause analysis, ensuring that the correct issues are being addressed.

- Corrective Action Implementation Rate: This metric tracks the percentage of corrective actions successfully implemented within the stipulated timeline, indicating the efficiency of the 8D corrective action process.

- Customer Satisfaction Improvement: Monitoring changes in customer satisfaction levels following the 8D corrective action process can highlight the impact of the process on overall product quality and customer perception.

8D Problem Solving Report

8D problem solving reports and templates are useful tools to initiate a problem solving process. These reports are used to explain what 8D is and including information about each step so that one will know what needs to be done by attempting this to solve problems. Keeping these reports easily available can avoid repeating work on the same problems over and over again.

8D reports must be detailed and incorporate information at every step within the 8D process. Those who are working on the problem should provide sufficient information when completing a report so that someone who was not on the current 8D team can pull it out and understand what the problem was and what solutions were implemented.

Improve quality, eliminate problems and identify the root cause of a problem with 8d Methodology

Who can 8d help.

The 8D methodology is universally applicable for every organization that needs solving. Although, there are a few industries and sectors where this 8D approach is successfully used such as manufacturing, the automotive industry , engineering companies that manufacture products or parts, and medium and large-scale enterprises.

Related Checklists

Quality Assurance Checklist – Part A (Project Management)

Checklist | September 7th, 2022

Quality Assurance Checklist – Part B (Project Deliverables)

Quality Control Area Safety Audit Checklist for Pharmaceutical Companies

Checklist | April 22nd, 2022

Implementing the 8D Root Cause Analysis

Establish the Team

- Assemble a cross-functional team: Ensure diverse perspectives and expertise.

- Define roles and responsibilities: Clarify each member's contributions.

- Team leader selection: Choose someone with strong leadership and problem-solving skills.

Describe the Problem

- Problem statement creation: Define the issue clearly and concisely.

- Use of data and evidence: Gather and present data to illustrate the problem.

- Scope and impact: Detail how the problem affects processes, products, or customers.

- Immediate actions: Implement temporary measures to contain the problem.

- Verification of ICAs: Ensure the containment actions are effective.

- Monitoring: Continuously monitor the situation until a permanent solution is found.

Determine Root Causes

- Root cause analysis techniques: Utilize tools like the 5 Whys and Fishbone diagrams.

- Data analysis: Examine data to identify patterns and anomalies.

- Identify multiple root causes: Look beyond the obvious to find all contributing factors.

Develop Permanent Corrective Actions (PCAs)

- Brainstorm solutions: Generate potential corrective actions.

- Evaluate effectiveness: Assess the feasibility and impact of each solution.

- Select the best solution: Choose the most effective and sustainable corrective action.

Implement and Validate PCAs

- Action plan creation: Develop a detailed plan to implement corrective actions.

- Execution: Carry out the corrective actions according to the plan.

- Validation: Verify that the corrective actions resolve the problem effectively.

- Standardization: Update processes, procedures, and documentation to include the new solutions.

- Training: Educate employees on the new procedures to ensure consistent application.

- Monitoring and review: Regularly review the effectiveness of the implemented solutions.

Recognize the Team and Celebrate Success

- Team recognition: Acknowledge the contributions of each team member.

- Celebrate achievements: Celebrate the success of solving the problem.

- Document lessons learned: Record insights and lessons learned for future reference.

Quality-centric Companies Rely on CQ QMS

Frequently Asked Questions

The 8D methodology is often used since it provides a consistent, simple, and thorough approach to solving raised problems at various stages. If properly applied, it gives several advantages such as:

A systematic approach for improving team-oriented problem solving skills

A clear understanding of basic statistical tools needed for problem solving

A practical understanding of the ‘ root cause analysis’ tool

Creating and expanding relative information about past failures and lessons learned to avoid future problems in the organization

Improving skills for corrective action deployment

When the team is trying to find the root cause of the problem and deploy corrective actions, some defective products will continue to be manufactured. To prevent these defective parts from reaching the customer, interim containment ensures that the defects are contained in the facility till the problem is completely solved. If defective parts reach the customer, it may result in warranty claims, field failures, and customer complaints.

To implement the 8D process successfully, the following factors are crucial:

The right team

An accurate description of the problem

Avoiding skipping through steps

Ensuring cooperation within the team and management support

Understanding the difference between real causes and possible causes

Related Insights

5 Dos and Don’ts When Choosing a QMS Solution for Your Enterprise

Every investment a business makes should have a measurable impact. In the case of an EQMS, the ROI is based…

Root Cause Analysis – Definition, Benefits and Process

All Quality and Safety Management Standards emphasize the importance of…

5 Why vs. Pareto Chart vs. Fishbone Diagram – Pros and Cons of Each of These RCA Techniques

All Quality Management Standards emphasize the importance of identifying the…

Automated CAPA with RCA and 5 Why to Make Your Workplace Healthy and Safe

PGT Innovations (PGT), pioneers in the impact-resistant window and door…

Connect with a CQ Expert

Learn about all features of our Product, Quality, Safety, and Supplier suites. Please fill the form below to access our comprehensive demo video.

Please confirm your details

By submitting this form you agree that we can store and process your personal data as per our Privacy Statement. We will never sell your personal information to any third party.

In Need of Smarter Ways Forward? Get in Touch.

Got questions we can help.

Chat with a CQ expert, we will answer all your questions.

8D Chess: How to Use The 8 Disciplines for Problem Solving

Hospitals have developed something of a reputation for being rife with bad processes . When processes aren’t adequate, the result is an abundance of “workarounds”.

For example, when equipment or supplies are missing, a nurse might waste time running around searching for what is needed, and once the item is found, return to their previous duties.

One study indicates that nurses spend 33 minutes of a 7.5-hour shift completing workarounds that are not part of their job description.

This may well “put out the fire” so-to-speak, but really it is just a hastily applied band-aid that does nothing to treat the root cause of the problem.

More time is wasted and more problems will arise in the future because nothing has been done to prevent the initial problem from happening again.

Individual nurses are not at fault here; workplace culture often values expertise in the form of those who “get the job done”, which tends to pull against the notion of spending time building good processes (time in which the job is perhaps not “getting done”).

So how to approach the problem of problem solving ?

In a lean context, problem solving can be distilled into two simple questions:

- What is the problem and how did it happen?

- How can we make sure that it doesn’t happen again?

The 8D, or eight disciplines methodology, is a problem solving process – most likely one of the most widely used problem solving processes out there. It is used by many different countries, in many different industries, and many different organizations.

8D is designed to help you put out those fires, and make sure they don’t happen again.

In this article, I’ll introduce you to the 8D problem solving methodology and provide you with an outline of the basic process that you can hopefully apply in your own business, plus how you can enhance 8D with other tools and methodologies like Six Sigma , FMEA , and Process Street .

Here’s what I hope you’ll take away after reading:

- An understanding of the basics of 8D

- Advantages of using 8D

- The purpose and objectives of each phase of the 8D process

- An understanding of how to use 8D for problem solving

- How 8D works with other problem solving tools

- How you can use Process Street to maximize the potential of the 8D framework

Let’s begin with the origins of 8D – what is it, and where did it come from?

What is 8D?

8D (sometimes Global 8D or G8D) stands for eight disciplines, and is a problem solving methodology. It’s basically a process for understanding and preventing problems.

Much like how risk management seeks to take a proactive, preventative stance, 8D aims to gain insight into the root causes of why the problems happen, so they won’t happen again.

The 8D process involves eight (sometimes nine) steps to solve difficult, recurring problems. It’s a transparent, team-based approach that will help you solve more problems in your business.

8D origins: Where did it come from?

Despite the popular story that 8D originated at Ford, it was in fact developed in 1974 by the US Department of Defence, ultimately taking the form of the military standard 1520 Corrective Action and Disposition System for Nonconforming Material .

Ford took this military standard, which was essentially a process for quality management , and expanded on it to include more robust problem solving methods.

In 1987, Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS) , which included their first iteration of the 8D methodology.

Initially termed Global 8D (or G8D) standard, it is currently used by Ford and many other companies in the automotive supply chain.

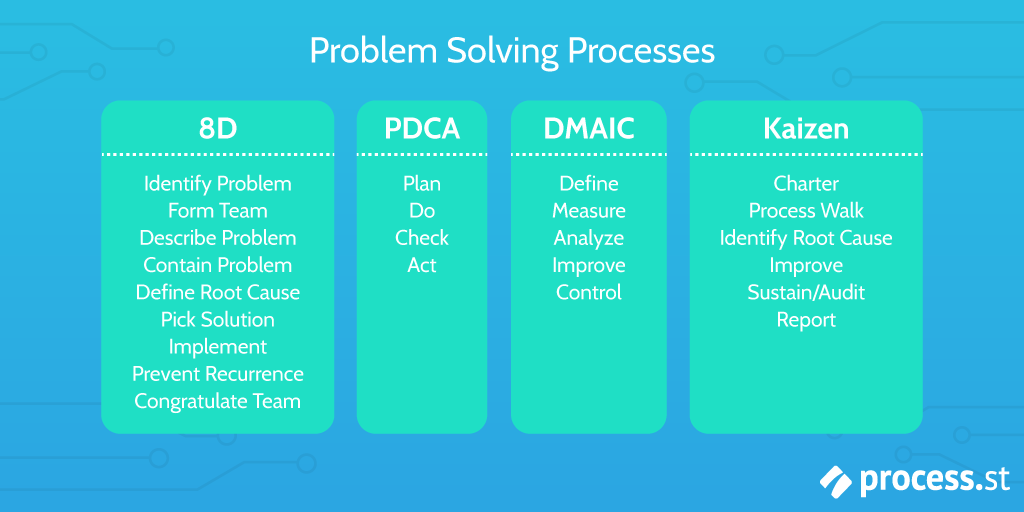

8D, PDSA, & other problem solving processes

The disciplines of 8D follow the same logic as the Deming Cycle (also known as PDSA, and sometimes PDCA).

PDSA stands for Plan, Do, Study, Act (or Check, in the case of PDCA).

The similarity lies in the fact that both PDSA and 8D are designed to be used to improve processes. They’re both examples of cycles of continuous improvement.

Whereas 8D may be painted as a more generic problem-solving framework, structurally speaking both 8D and PDSA share a lot in common.

The simple idea of beginning with a clear objective, or desired output, and then testing, analyzing , and iteratively tweaking in a continuous cycle is the basis for both methodologies.

There are, of course, differences. We’ll cover the different applications of both 8D and PDSA in this article.

8D advantages

One of the main strengths of 8D is its focus on teamwork. 8D philosophy encourages the idea that teams, as a whole, are more powerful than the sum of the individual qualities of each team member.

It’s also an empirical methodology; that is to say that it is a fact-based problem solving process.

A branch of continuous improvement, proper use of 8D will help you coordinate your entire team for effective problem solving and improved implementation of just about all of the processes used in your business.

The 8 disciplines for problem solving

As you may have noticed, we’re starting with zero, which makes nine total disciplines. This “zero” stage was developed as an initial planning step.

D0: Plan adequately

Make comprehensive plans for solving the problem including any prerequisites you might determine.

Be sure to include emergency response actions.

D1: Establish your team

Establish your core team with relevant product or process knowledge. This team will provide you with the perspective and ideas needed for the problem solving process.

The team should consist of about five people, from various cross-functional departments. All individuals should have relevant process knowledge.

A varied group will offer you a variety of different perspectives from which to observe the problem.

It is advisable to establish team structure, roles, and objectives as far ahead in advance as possible so that corrective action can begin as quickly and effectively as possible.

D2: Describe the problem

Have your team gather information and data related to the problem or symptom. Using clear, quantifiable terms, unpack the problem by asking:

D3: Contain the problem (temporary damage control)

Depending on the circumstances, you may need to mobilize some kind of temporary fix, or “firefighting”.

The focus of this stage should be on preventing the problem from getting worse, until a more permanent solution can be identified and implemented.

D4: Identify, describe, and verify root causes

In preparation for permanent corrective action, you must identify, describe, and verify all possible causes that could contribute to the problem happening.

You can use various techniques for this, including a Failure Modes and Effects Analysis , or Ishikawa (fishbone) diagram .

It’s important that the root causes are systematically identified, described in detail, and promptly verified (or proved). How each cause is verified will depend on the data type and the nature of the problem.

Take a look at the section towards the end of this article for some more problem solving tools to help you decide the right approach.

D5: Identify corrective actions

You must verify that the corrective action you identified will in fact solve the problem and prevent it from happening again in the future (or whatever is your desired threshold of recurrence).

The best way to do this is to collect as much data as possible and by performing smaller-scale “pilot” tests to get an idea of the corrective action’s impact.

You can’t begin to identify the optimal corrective action until you have identified the root cause(s) of the problem.

D6: Implement and validate corrective actions

Carry out the corrective actions, and monitor short and long term effects. During this stage, you should assess and validate the corrective actions with empirical evidence.

Discuss and review results with your team.

D7: Take preventative measures (to avoid the problem happening again)

Here is where you make any necessary changes to your processes, standard operating procedures , policies , and anything else to make sure the problem does not happen again.

It may not be possible to completely eliminate any chance of the problem recurring; in that case, efforts should focus on minimizing possibility of recurrence as much as possible.

D8: Congratulate your team

It’s important to recognize the joint contribution of each and every one of the individuals that were involved in the process.

Team members should feel valued and rewarded for their efforts; this is crucial and perhaps the most important step – after all, without the team, the problem would not have been fixed.

Providing positive feedback and expressing appreciation helps to keep motivation high, which in turn improves the sense of process ownership and simply increases the likelihood your team will actually want to improve internal processes in the future.

How to use 8D for problem solving

The 8D method above outlines a proven strategy for identifying and dealing with problems. It’s an effective problem solving and problem prevention process.

In addition to avoiding long-term damage from recurring problems, 8D also helps to mitigate customer impact as much as possible.

More than just a problem-solving methodology, 8D sits alongside Six Sigma and other lean frameworks and can easily be integrated with them to minimize training and maximize efficacy.

8D is definitely a powerful framework on its own, but it really shines when combined with other synergistic concepts of lean and continuous improvement.

More problem solving tools that synergize well with 8D

8D has become a leading framework for process improvement, and in many ways it is more prescriptive and robust than other more simplistic Six Sigma approaches.

However, there are many Six Sigma methodologies, and even more frameworks for problem solving and process improvement .

The following improvement tools are often used within or alongside the 8D methodology.

DMAIC: Lean Six Sigma

DMAIC stands for:

The DMAIC process is a data-driven cycle of process improvement designed for businesses to help identify flaws or inefficiencies in processes.

Simply put, the goal with DMAIC is to improve and optimize existing processes.

Interestingly, the development of the DMAIC framework is credited to Motorola , whose work built upon the systems initially developed by Toyota .

In terms of working alongside 8D, you could use DMAIC to identify root causes as in D4; you could also implement the same techniques to better understand prospects for corrective actions as in D5, and D6.

We have a whole article on the DMAIC process, if you’re interested.

SWOT analysis

Strengths, Weaknesses, Opportunities, and Threats. You can use a SWOT analysis to gain insight into your organization as a whole, or on individual processes.

The main synergy with 8D is in the identification of opportunities, threats, and weaknesses.

These can represent opportunities for process improvements, weaknesses in your process that could produce problems further down the line, and threats, both internal and external, that may be out of your direct control but that could cause problems for you.

Here’s a SWOT analysis checklist you can use to structure your own analysis:

FMEA: Failure Mode and Effects Analysis

FMEA (Failure Mode and Effects Analysis) is a way of understanding the potential for problems and making preemptive preparations in order to avoid them. It is a method of risk management .

It is a type of preventative risk management process, and so works well in the context of identifying causes of problems so you can better deal with them.

FMEA and 8D work well together because:

- 8D can make use of information gathered during an FMEA process, like brainstorming sessions, to identify potential problems and their root causes.

- You can reuse possible cause information gathered during an FMEA process to feed into different representational diagrams like the Ishikawa (fishbone) diagram, which will help in the 8D process.

- 8D brainstorming data is useful for new process design. This allows the FMEA to take actual process failures into account, which produces more effective results.

- FMEA completed in the past can be used as databases of potential root causes of problems to inform 8D process development.

Here’s a free FMEA template for you to get started ASAP:

The Pareto Chart

The Pareto Chart helps us understand the impact of different variations of input on our output.

In relation to 8D, Pareto Charts can help us prioritize which root cause to target, based on which will have the greatest impact on improvement (where improvement is the desired output of the 8D process).

Here’s the Six Sigma Institute’s example Pareto Chart :

Here we have a simple deductive reasoning technique that asks “why?” five times to dig into the root cause of a problem.

The logic here is that by asking the same question five times, you work progressively “deeper” into the complexity of the problem from a single point of focus.

Ideally, by the fifth question you should have something that has a high likelihood of being a root cause.

This example from Wikipedia does a great job of conveying how the process works:

- The vehicle will not start. (the problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

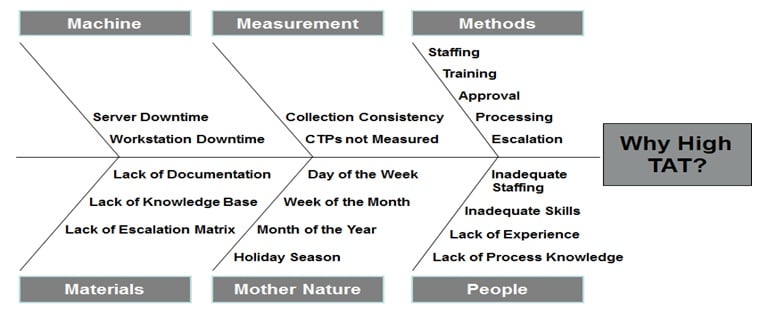

Ishikawa diagrams (fishbone diagrams)

Sometimes called “cause-and-effect diagrams”, they are as such used to visualize the cause and effect of problems.

The approach takes six different categories and places information about the problem into different categories to help you understand what factors could be contributing to the problem.

One advantage over the 5 Whys approach is the way this method forces a more holistic perspective, as opposed to the potentially narrow vantage point offered by zooming in on a single aspect or question.

According to the Six Sigma Institute, the 6 key variables pertaining to root causes of problems are:

- Machine: Root causes related to tools used to execute the process.

- Material: Root causes related to information and forms needed to execute the process.

- Nature: Root causes related to our work environment, market conditions, and regulatory issues.

- Measure: Root causes related to the process measurement.

- Method: Root causes related to procedures, hand-offs, input-output issues.

- People: Root causes related people and organizations.

There’s also this useful illustration of a company using a fishbone diagram to better understand what factors contribute to a company’s high turn around time.

Gap analysis

A gap analysis is concerned with three key elements:

- The current situation, or “performance”

- The ideal situation, or “potential”

- What needs to be done in order to get from performance to potential, or “bridging the gap”

The “gap” is what separates your current situation from your ideal situation.

Businesses that perform a gap analysis can improve their efficiency and better understand how to improve processes and products.

They can help to better optimize how time, money, and human resources are spent in business.

There’s a lot that goes into a gap analysis, and quite a few different ways to approach it. Check out our article for a deeper dive into the gap analysis process.

Superpowered checklists

Checklists can be a great way to simplify a complex process into a series of smaller, easy-to-manage tasks. They’re one of the best ways to start using processes in your business.

By using checklists, you can reduce the amount of error in your workflow , while saving time and money by eliminating confusion and uncertainty.

What’s more, if you’re using Process Street, you have access to advanced features like conditional logic , rich form fields and streamlined template editing .

How to use Process Street for 8D problem solving

Good problem solving relies on good process. If you’re trying to solve problems effectively, the last thing you want is your tools getting in your way.

What you want is a seamless experience from start to finish of the 8D methodology.

The best kinds of processes are actionable. That’s why you should consider using a BPM software like Process Street to streamline recurring tasks and eliminate manual work with automation .

Process Street’s mission statement is to make recurring work fun, fast, and faultless. By breaking down a process into bite-sized tasks , you can get more done and stay on top of your workload.

Sign up today for a free Process Street trial!

Problem solving is an invaluable skill. What’s your go-to process for problem solving? We’d love to know how it compares with the 8D method. Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

Designorate

Design thinking, innovation, user experience and healthcare design

What is the 8D Problem Solving? And How to use the 8D Report?

The 8D problem-solving process (also known as the 8 Disciplines) is very different from previous processes we explored previously, such as the Double Diamond process or the IBM Design Thinking. The 8D process works in a rigid standardised nature to address the crisis caused by problems. The 8D process aims to walk with the team to highlight the problem, its root causes and propose a long-term solution. The process is documented in an 8D report which includes details of each of the eight stages. At the end of this article, we will explore an example report, and you can find a free 8D report template to download.

In times of crisis, companies face the challenge of analysing and solving problems efficiently in a short time to save developed projects. Problem-solving techniques such as the TRIZ method and Hurson’s Production Thinking Model allow companies to overcome crises and solve problems using less effort and time.

- Stage Gate Process: The Complete Practice Guide

- The Double Diamond Design Thinking Process and How to Use it

- A Guide to the SCAMPER Technique for Creative Thinking

- Design Thinking Tools: Reverse Brainstorming

Brief History of the 8D Problem Solving

The 8D method was first implemented by the US government during WW II as a military standard and was referred to as the Army Directive 1520, “Remedies and disposal of nonconforming materials.” In 1987, the demand for a team-oriented problem-solving method increased among the management organisation in the automotive industry to find a way to eliminate recurring issues.

Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS), which includes their 8 Disciplines of the problem-solving process. The process was initially used to deal with quality control and safety issues inside the company but later expanded its role to a team approach problem-solving method. The 8D process is employed by engineers and designers to identify, analyse, and correct problems by eliminating the primary source that caused the problem.

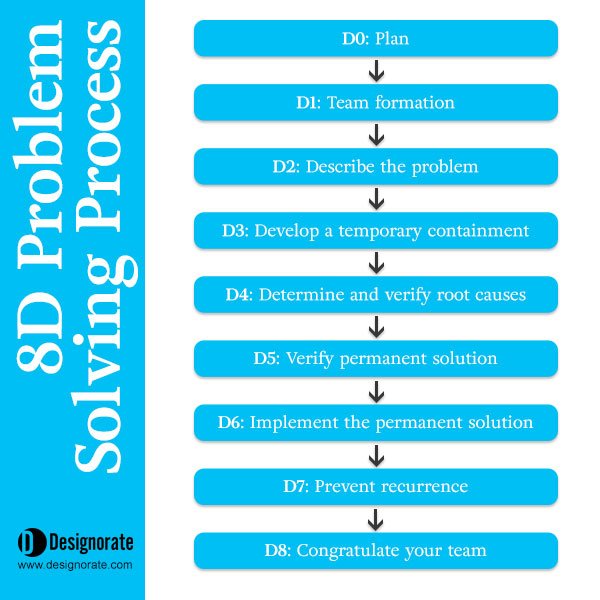

So, what are the eight steps in the 8D methodology? The 8D problem solving process includes 8 Disciplines. In the mid-90s, a D0 step for planning was added to the process. The 8D steps include the following:

- D1: Team formation

- D2: Describe the problem

- D3: Develop a temporary containment plan

- D4: Determine and verify root causes

- D5: Verify the permanent solution

- D6: Implement the permanent solution

- D7: Prevent recurrence

- D8: Congratulate your team

The 8 Disciplines aim to achieve the following targets while solving the specified problem:

- Think as a team while solving the problem

- Isolate the situation and understand its causes

- Identify the factors that contribute to the problem

- Provide a temporary solution to halt the impact of the problem

- Eliminate the causes of the problem and the factors contributing to it

- Prevent the problem from recurring

When Should the 8D Problem Solving be Used?