Published: November 7, 2018 by Ken Feldman

The fundamental premise of the Shainin Red X® process is that for any problem, there is a dominant root cause that must be eliminated or mitigated for the process to be improved. In this article, we will define the Red X process, best practices, and how it can be applied to your organization.

Overview: What is Red X?

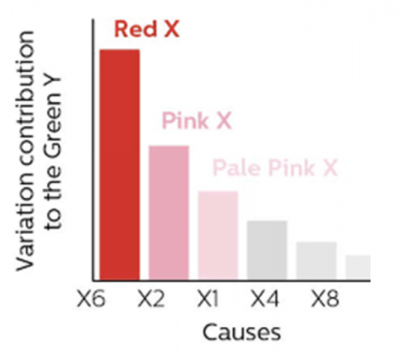

The Red X method is based on the key assumption there is always a dominant cause of variation. This statement is based on the application of the Pareto principle to the causes of the variation. Generally, the variation of the output is caused by the variation of several inputs. These inputs (Xs) are categorized by color, with the Red X being the dominant root cause. Shainin defines the desired state of the output as the GreenY®.

Red X Pareto Chart

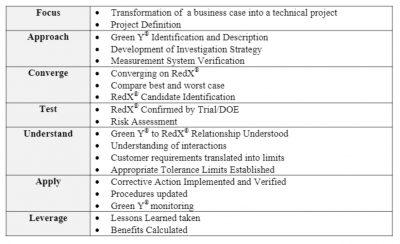

Instead of the DMAIC methodology of Define-Measure-Analyze-Improve-Control, the Red X approach uses the following structure, called FACTUAL:

Shainin Red X FACTUAL approach to problem-solving

An industry example of Red X

The problem was Post Burning Blow Holes on automotive batteries. The post burner is an automatic burning machine designed to weld the cylindrical bushing of an automotive battery to a specified depth of burn. If blow holes are seen on the battery post, then the battery is rejected.

Shainin Red X techniques were used to reduce the percentage of reworks from 0.15% to 0.03%. DOE was used as the primary tool along with:

- Multivari analysis

- Variable search

- Paired comparison

- Component search

- Product / process search

- Scatter plots

3 best practices when thinking about Red X

Here are a few tips on using Red X in your organization.

1. Deep understanding of the process

You must have a deep understanding of the Y and the problem.

2. Problem solving strategy

The Red X approach is very diagnostic in nature. It is the identification, analysis and quick zooming in on the root cause.

3. Measurement System Analysis (MSA)

You must have confidence in the quality of the data captured by your measurement system. This requires you to do a MSA study to validate your data.

Frequently Asked Questions (FAQ) about Red X

1. what are some of the common tools used in red x .

Two of the most common tools used in Red X are the Solution Tree™ developed by Shainin, Pareto Chart and full factorial design of experiments . Other tools include the Shainin ISO plot, component search, paired comparison, multi-vari chart and BOB/WOW.

2. What do BOB and WOW mean in Red X?

One of the techniques used in Red X is to examine the extremes to try and identify a possible root cause. You will look at the Best of the Best (BOB) versus the Worst of the Worst (WOW).

3. Who developed the Red X approach?

Dorian Shainin (1914-2000) was an American quality consultant, aeronautical engineer, and author primarily noted for his contribution in the field of problem-solving, specifically the creation and development of the Red X concept.

Red X in a nutshell

Red X is a problem-solving technique based on the premise there is one dominant root cause for process variation and problems. Using a convergent process of analysis focusing on potential process input variables (X), the end result will be an identification of the primary Red X root cause along with lesser colors of Pink Xs.

About the Author

Ken Feldman

- How We Work

- Remember me Not recommended on shared computers

Forgot your password?

Or sign in with one of these services

- We ask and you answer! The best answer wins!

Red X Methodology

- red x methodology

- lean six sigma

- shainin red x

Asked by Vishwadeep Khatri , January 31, 2023

Red X Methodology (or the Shainin System) is a problem solving methodology which states that for every problem there is a prominent root cause (or a Red X). In order to solve the problem and get the desired output (Green Y), the Red X must be eliminated.

An application-oriented question on the topic along with responses can be seen below. The best answer was provided by Balaji Loganathan on 1st Feb 2023.

Applause for all the respondents - Balaji Loganathan, Vikas Choudhary, Anupam Goswami, Kirpa Shanker Tiwari, Nunhuck Oosman.

Vishwadeep Khatri

Q 537. What is Shainin Red X Methodology? Compare it with Six Sigma and highlight its pros and cons.

Note for website visitors - Two questions are asked every week on this platform. One on Tuesday and the other on Friday.

- All questions so far can be seen here - https://www.benchmarksixsigma.com/forum/lean-six-sigma-business-excellence-questions/

- Please visit the forum home page at https://www.benchmarksixsigma.com/forum/ to respond to the latest question open till the next Tuesday/ Friday evening 5 PM as per Indian Standard Time. Questions launched on Tuesdays are open till Friday and questions launched on Friday are open till Tuesday.

- When you respond to this question, your answer will not be visible till it is reviewed. Only non-plagiarised (plagiarism below 5-10%) responses will be approved. If you have doubts about plagiarism, please check your answer with a plagiarism checker tool like https://smallseotools.com/plagiarism-checker/ before submitting.

- The best answer is always shown at the top among responses and the author finds honorable mention in our Business Excellence dictionary at https://www.benchmarksixsigma.com/forum/business-excellence-dictionary-glossary/ along with the related term

Link to comment

Share on other sites, 6 answers to this question.

- Sort by votes

- Sort by date

Recommended Posts

Balaji loganathan.

Shainin RED X projects are evidence-based; converging on the main source of variation, the emphasizing principle is DY = f(Dx)The largest value will result from a combination of a significant coefficient and a large change in X.

What is the difference between Shainin and Six Sigma?

The main difference between the Shainin Red X® approach ( FACTUAL ) and the Six Sigma methodology ( DMAIC ) is the phase Approach . The Red X develops a strategy based upon the physics of the problem and the comparison of the BOB (Best of Best) and WOW (Worst of Worst) parts

Any problem-solving methodology involves two phases’ diagnostic and remedial phases. The diagnostic phase is concerned with measuring and analyzing the current process performance while the remedial phase involves of various corrective actions taken to improve the process and monitoring the new process to make it a culture.

Tables show the comparison between the six sigma and Shainin methodological approaches.

Vikas Choudhary

Shainin Red X Methodology is a problem-solving technique used in the manufacturing and engineering industries to identify the root cause of a particular issue quickly and effectively. It's a data-driven approach that utilizes statistical analysis, hypothesis testing, and experimentation to isolate the key factor causing the problem.

Compared to Six Sigma, Shainin Red X Methodology is a more streamlined and quicker approach to problem-solving. While Six Sigma is a comprehensive methodology that can take several weeks or months to complete, Shainin Red X can often find the root cause in a matter of days or even hours.

Pros of Shainin Red X Methodology include:

- Faster problem-solving times

- Reduced number of trial and error tests

- Higher accuracy in identifying root cause

- Emphasis on simplicity, making it easy for non-experts to understand and participate in the problem-solving process.

Cons of Shainin Red X Methodology include:

- Limited scope, as it's mainly focused on identifying root cause and not on process improvement or optimization.

- May not be suitable for complex problems or those requiring a deeper understanding of the underlying systems and processes.

Overall, Shainin Red X Methodology can be an effective tool for solving problems quickly in specific cases, but it may not always be the best choice for all situations.

Anupam Goswami

Shainin Red X Methodology is a statistical problem-solving approach used in industrial settings to quickly identify the root cause of complex and multifaceted issues. It is based on the idea that a small number of critical inputs (often referred to as the dominant "X's" based on pareto principle) are responsible for most of the variation in a system. The methodology involves a systematic process of testing, eliminating, and validating these inputs until the root cause of the issue is found.

Compared to Six Sigma, Shainin Red X Methodology is considered to be a more efficient and quicker approach to problem-solving, particularly when dealing with complex, multivariate issues. Six Sigma, on the other hand, is a more comprehensive process improvement methodology that involves extensive data analysis, statistical process control, and a structured DMAIC (Define, Measure, Analyze, Improve, Control) process.

Pros of Shainin Red X Methodology:

· Quicker problem resolution time

· Focuses on critical inputs for efficient problem-solving

· Can be applied to a wide range of industrial settings

· Can be used by individuals with limited statistical knowledge

Cons of Shainin Red X Methodology:

· May not be as comprehensive as other problem-solving approaches such as Six Sigma

· May not be suitable for all types of problems, particularly those that are not complex or multivariate in nature

· Can be less data-driven compared to other methodologies, relying more on intuition and experience of the problem-solver.

Pros of Six Sigma:

· Comprehensive approach to problem-solving and process improvement

· Utilizes statistical tools and methodology to identify and eliminate causes of defects

· Can be applied to a wide range of industries and processes

Cons of Six Sigma:

· Can be time-consuming and resource-intensive to implement

· May not be as quick as Shainin Red X Methodology in solving specific problems.

In summary, Shainin Red X Methodology is a fast and effective approach to solving complex problems, but it may not be as comprehensive as other methodologies like Six Sigma. The choice of methodology depends on the type and complexity of the problem, as well as the resources available.

kirpa Shanker Tiwari

The Shainin System is develop by Dorian Shainin . It is a tool for statistical engineering and generally used in Automobile sector. Shainin also called Red –X strategy. This is typically used to high volume processes where huge database exist and ease of data availability. This system is used in parts and assembly manufacturing processes.

This work on below underlying principles

1. Assumption that there are large cause of variations

2. Assumptions there is diagnostic processes and remedial actions.

Steps of Shainin system

1. define the project

2. Establish Measurement system

3. generate hints

4. list probable factors

6. found Red –X

7. Check interactions

8. Irreversible corrective actions

10. monitor outcome

11. Consumer satisfaction

How it is different than Six sigma

Six sigma is more statistical however this is based on Statistics and more mechanistic.

Shainin is systems that are developed to achieve six sigma targets

Shainin systems are evidence based and covers maximum source of variations.

Shainin systems generally used FACTUAL path while Six sigma used DMAIC kind of methodology.

FACTUAL: Focus>>Approach>> converge>>Test >> understand>> Apply >> leverage

DMAIC: Define>> Measure>> Analyse>> Improve>> Control.

Nunhuck Oosman

The Shainin X methodology is described as a system for resolving issues created for medium- to high-volume processes where data are easily accessible, statistical techniques are frequently employed, and process intervention is challenging. It has mostly been used in facilities for part and assembly processes.

The basic principality of the Red X technique is that there is always a dominant cause of variation. This claim is supported by the Pareto principle's application to the causes of the variance. Usually, changes in a number of inputs lead to changes in the output. These inputs (Xs) are divided into groups based on color, with the Red X serving as the primary cause. The GreenY state is how Shainin describes the desirable state of the output.

Using Shainin tools has the benefit of requiring very low sample sets for problem analysis. Frequently, samples of just two or three are sufficient to draw statistically significant results. The data can be analyzed without the use of computerized statistical methods.

Moreover underlying causes are identified through "interacting to the parts" as opposed to assumptions or preconceived notions.

Due to the statistically robustness of the procedures, main effects and interaction effects were distinguished and quantified.

A great variety of versatility is offered by the 12 various approaches.

It is simpler to incorporate the entire workforce because the strategies are simple to implement and inexpensive to learn.

The below four groups can be used to group the 12 techniques:

- Generation Clue: Until the fundamental cause can be isolated, quasi causes of variation are removed using the multi-vari analysis filtering technique.

- Pictograph: Used to indicate where a flaw is located on a component, in a design, or on a grid. Either a random pattern or a concentration in a specific location will result (s).

- Components Search: To identify the source of the issue, parts and sub-assemblies are switched between good and problematic products.

-Comparing the greatest and worst product examples side by side will help you identify the traits or factors that set the best and worst goods apart.

List and quantify the process variables in the product/process search

-Search for Products/Processes: The process variables that affect a product's quality should be listed and measured. By contrasting data from a process that yields good parts with measurements from a process that yields faulty parts, you can identify which of these process factors is to blame for the problem.

DOE optimization

- By displaying one variable against the other, a scatterplot (also known as a scatter diagram) can be used to visually depict the relationship between two variables.

- RSM, or Response Surface Methodology When we want to improve the settings of the essential elements in a process once they have been isolated, we apply a DOE technique. When we are aware of or believe that the response variable has curvature (i.e., non-linearity), we use RSM designs.

DOE approach

- Variables Search: A grid search approach that distinguishes between significant and minor process variables through testing the optimal and limiting values for each variable

- Complete factor analyses: These tests cover all possible combinations of variables, and all of their interconnections, and work best when there are just a few variables that have a big effect on the answer variable. They take longer and cost more to execute than screening methods.

- B vs. C: B stands for the superior or improved method, whilst C stands for the existing process. Six samples—three B samples and three C samples—are used in the test. According to the Law of Combinations, there is simply one possibility in 20 that all three Bs will outrank all three Cs, providing us 95% certainty that this is not a coincidence.

- Positrol (or precontrol): Items are rated as red, yellow, or green depending on how closely they adhere to the standard or tolerance. Green represents the tolerance's middle portion; yellow represents its second half; and red represents the tolerance's upper limit. How frequently the process requires change determines the sampling frequency. Continue running if a specimen is green. Choose another sample if the first one is yellow. Stop the process and tweak or modify it if the second piece is yellow. If any of the samples are red, halt the procedure and make any necessary adjustments.

- The Process Certification (Process Control, and Management Plan) specifies the who, how, where, and when of controls that will guarantee that the significant variables or factors are kept under control.

- Mayank Gupta

Balaji Loganathan has provided the best answer to this question.

Response from Oosman is also a must read.

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Already have an account? Sign in here.

Who's Online (See full list)

- Rohit Gandhi

Forum Statistics

- Total Topics 3.3k

- Total Posts 16.8k

Member Statistics

- Total Members 55,129

- Most Online 990 January 13, 2023

- Existing user? Sign In

- Think Pieces

- Guest Posts

Discussions on Topics

- Hypothesis Testing

- Business Analytics

- Customer Satisfaction

- Metrics and Measurement Systems

- DFSS - Design for Six Sigma

- Lean Management

- Root Cause Analysis

- Problem Solving Methodologies

- Efficiency and Productivity

- Online Green Belt

- Online Black Belt

- Create New...

- Search forums

- Common Quality Assurance Processes and Tools

- Problem Solving, Root Cause Fault and Failure Analysis

Problem Solving Methodology Help - Shainin/Red X

- Thread starter ByronD

- Start date Sep 7, 2011

- Sep 7, 2011

I have a two-part question. First, I would like some opinions regarding the relative ease of implementing the Shainin System (SS) in an organization where formal problem solving is relatively new – this in the context of A3 and Six Sigma. Also, does SS deal with the bigger picture of managing/prioritization of projects as does Six Sigma, or is it simply a method applied to a problem. FYI - We have people within the company trained in Six Sigma Methodology, but are without experience, formality (dashboards), dedicated BB resources, or infrastructure for directing/managing/ formal Six Sigma projects – we do use some of the tools however. On the other end of the complexity scale, we have begun using A3 problem solving, using a team approach. I am happy with the results so far for “mid-level” complexity problems. However some our more involved problems we are now asked to work on have to do with improving the RTY on key value streams – these consist of 20+ process steps. Such a project likely has many facets and consequently seems too unwieldy for an A3. If you feel strongly otherwise, please discuss. The second part of my question actually hinges on the first, but is a request for recommendations for a book to learn about SS. Has anyone reviewed both “World Class Quality” by Bhote and Statistical Engineering by Steiner and Mackay, or have other recommendations? Thank you.

Forum Moderator

The Shainin System is a good approach for problem solving. It is very difficult to find information about it without actually taking their classes, but the book Statistical Engineering: An Algorithm for Reducing Variation by Stefan H. Steiner is an excellent resource. While different enough to avoid copyright issues, it covers essentially the same approach. SS and SE will handle a wide range of problems of equal to greater complexity than A3, but not quite as complex as Six Sigma. It does have a process, but does not have the superstructure that Six Sigma has. It is more suited to special cause problems, or recurring problems, while Six Sigma is more suited for Common Cause problems. I have found Bhote to be a little dogmatic about Taguchi Methods. While good, they are not quite the panacea that Bhote makes out.

Miner said: SS and SE will handle a wide range of problems of equal to greater complexity than A3, but not quite as complex as Six Sigma. It does have a process, but does not have the superstructure that Six Sigma has. It is more suited to special cause problems, or recurring problems, while Six Sigma is more suited for Common Cause problems. I have found Bhote to be a little dogmatic about Taguchi Methods. While good, they are not quite the panacea that Bhote makes out. Click to expand...

Heretical Statistician

I agree that Statistical engineering is a much better book if you can only afford one. I strongly disagree with Miner (repsectfully) that statitistical engineering is not for common cause problems - in my experience it is excellent for solving complex common cause problems...I do it all of the time. (for what it's worth my view is that special cause and common case are operational definitions that only have meaning in the context statistical process control. All results have a physical cause and it can be determined) I view the Shainin System as a special subset of tools and strategy that falls under the classification of effect to cause (starting at the Problem side and working back to find the causal mechanism; Kepner-Tregoe, SE and Why-Why are also in this category) where most common approaches (fishbone diagramming and brainstorming) are in the classification of cause to effect.

Bev D said: I agree that Statistical engineering is a much better book if you can only afford one.. Click to expand...

Bev D said: I strongly disagree with Miner (repsectfully) that statitistical engineering is not for common cause problems - in my experience it is excellent for solving complex common cause problems...I do it all of the time. (for what it's worth my view is that special cause and common case are operational definitions that only have meaning in the context statistical process control. All results have a physical cause and it can be determined) Click to expand...

Bev D said: I view the Shainin System as a special subset of tools and strategy that falls under the classification of effect to cause (starting at the Problem side and working back to find the causal mechanism; Kepner-Tregoe, SE and Why-Why are also in this category) where most common approaches (fishbone diagramming and brainstorming) are in the classification of cause to effect. Click to expand...

- Sep 8, 2011

ByronD said: It may be factual - not sure - that special cause may be easier (cheaper/quicker) to eradicate Click to expand...

- how deeply the cause is buried in the system

- the occurence rate (to an extent the if the problem characteristic can be measured with continuous data can be faster than when we can only count the nubmer of good/bad events

- the ability to actually measure or see the Problem characteristic and it's system of inputs.

ByronD said: ...can you differentiate between effect to cause vs. cause to effect? I fear I may be missing something important here… a fishbone has a single effect and the thought process to determine what “factors” may be a causal subset leading to this effect? While effect to cause is the opposite??? There may be one or several effects (defects for instance) for which a common cause is sought Click to expand...

- Sep 12, 2011

ByronD said: ...can you differentiate between effect to cause vs. cause to effect? I fear I may be missing something important here… a fishbone has a single effect and the thought process to determine what “factors” may be a causal subset leading to this effect? While effect to cause is the opposite??? There may be one or several effects (defects for instance) for which a common cause is sought?[/FONT][/COLOR] Click to expand...

- Conjecture, potential causes are listed based on: Brainstorming → fishbone diagrams → multi-voting

- Proves a cause creates an effect

- Swing for the fence

- Divergent – random searches

- One factor testing or fractional factorials

- Requires us to be able to 'know' what the input factors are

- Focus is on how the system works

- potential causes are evidenced based

- Disproves potential causes

- Considers all potential causes and tests all of them simultaneously

- Iterative approach

- Quick tight experiments

- Requires us to understand the function of the system

- Focus is on how the system fails

- Sep 13, 2011

- Sep 14, 2011

ByronD said: ...I am interested in pursuing training for myself and other engineering personnel. If you have any recommendations I would appreciate hearing them Click to expand...

- Temporal - Within piece, piece to piece, lot to lot, vendor lot to lot, month to month, season to season etc. - Product use: during use, use to use - Operator to operator - Within a process; step to step or operation to operation.

- Structural - Location (Within piece, cavity to cavity, station to station, line to line, plant to plant, region to region) - Components (Sub-assemblies, Component parts, Raw materials, Process step (assembly or process methods)) - Specific features, dimensions and/or properties

Stop X-bar/R Madness!!

Bev D said: Actually I've found this to be a myth...The real drivers of how easy or difficult it is to determine the causal mechanism lies in 3 factors: how deeply the cause is buried in the system the occurrence rate (to an extent the if the problem characteristic can be measured with continuous data can be faster than when we can only count the number of good/bad events the ability to actually measure or see the Problem characteristic and it's system of inputs. Click to expand...

Similar threads

- iMPact Business Group

- Jun 5, 2023

- Job Openings, Consulting and Employment Opportunities

- Feb 6, 2023

- General Information

- Oct 26, 2020

- Lean in Manufacturing and Service Industries

- Feb 18, 2015

- May 14, 2012

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to the use of cookies. Accept Learn more…

IMAGES

VIDEO

COMMENTS

The Shainin System, developed by Dorian Shainin, is a structured method for solving complex problems. Technical problems are addressed using Red X Problem Solving to drill down to the hidden source of the problem. Business process problems are addressed using TransaXional, a function-based approach to reveal where the process is breaking down.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

In this webinar, Serge Guillot, Senior Engineer at Shainin - The Red X Company, looks at another very successful problem-solving approach that has been used ...

Developing Effective Red X® Problem Solvers By Richard D. Shainin, Executive Vice President Seattle Washington, 18 April, 2018 Red X® problem solving is a skill that needs to be learned and developed. As with any skill, students must pass through four phases of competence before they are fully developed. We all start out

Dorian Shainin (1914-2000) was an American quality consultant, aeronautical engineer, and author primarily noted for his contribution in the field of problem-solving, specifically the creation and development of the Red X concept. Red X in a nutshell. Red X is a problem-solving technique based on the premise there is one dominant root cause for ...

The Shainin System™ (SS) is a problem-solving system and its associated strategies and tools developed by Dorian Shainin. Shainin's consulting firm offers the system, also referred to as Statistical Engineering, under the trademarked name Red X® Strategy. Although widely used and promoted in manufacturing, SS is not well documented or ...

Structured Problem Solving and Shainin's Red X Methodology. To learn more about Shainin's Problem Solving Services, click here:https://shainin.comFollow us o...

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

The Shainin System is also known by a more descriptive moniker, "Red X Problem Solving," owing to its focus on the single largest contributor to process variation. It has been developed to be statistically rigorous, while keeping complex statistics in the background.

Judgmental statistics are used to prove cause-effect relationships. In Red X ® Problem Solving we call this taking the Red X to court. A B vs. W™ test proves the identity of the Red X. A six pack achieves that proof with a 5% risk that we've been fooled by the data. B vs. C™ tests assess if a proposed improvement is better than the ...

system as the problem-solving methodolog y stands (Shainin, 1993): For every effect there is dominant root-cause. The fastest way to identify the root-cau se is through a search using

Dorian Shainin (September 26, 1914 - January 7, 2000) was an American quality consultant, aeronautics engineer, author, and college professor most notable for his contributions in the fields of industrial problem solving, product reliability, and quality engineering, particularly the creation and development of the "Red X" concept.. Shainin (pronounced SHAY-nin), founder of the technical ...

Previous Next. Red X® problem solving is a skill that needs to be learned and developed. As with any skill, students must pass through four phases of competence before they are fully developed. We all start out Unconsciously Incompetent: we don't know what we don't know. When we become exposed to a new skill, we suddenly become Consciously ...

An introduction to Shainin Red X problem solving methodology. If you seek to understand new methods of problem solving for business using the best and most e...

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

Red X Methodology (or the Shainin System) is a problem solving methodology which states that for every problem there is a prominent root cause (or a Red X). In order to solve the problem and get the desired output (Green Y), the Red X must be eliminated. An application-oriented question on the topic along with responses can be seen below.

The 2-day Red X ® Technician class provides an introduction to the Red X ® tools and strategies necessary to effectively support the engineering team in solving complex problems. In short, the training ensures everyone on the team speaks the same problem-solving language in their pursuit of hidden causes.

Admin. Sep 7, 2011. #2. The Shainin System is a good approach for problem solving. It is very difficult to find information about it without actually taking their classes, but the book Statistical Engineering: An Algorithm for Reducing Variation by Stefan H. Steiner is an excellent resource.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.

Tom is a certified Shainin RT5 leader and Red-X Journeyman, as well as a Six Sigma Plus Blackbelt, with a deep understanding of OpEx, Lean, Six Sigma, and Red-X problem-solving methods. He holds a Bachelor of Science in Mechanical Engineering and a Masters of Manufacturing Management, both from The Pennsylvania State University.