| | | ( ) and

Additional contact information

Ercan Oztemel: Marmara University Engineering Faculty

Samet Gursev: Marmara University Engineering Faculty , 2020, vol. 31, issue 1, No 9, 127-182 Abstract Manufacturing industry profoundly impact economic and societal progress. As being a commonly accepted term for research centers and universities, the Industry 4.0 initiative has received a splendid attention of the business and research community. Although the idea is not new and was on the agenda of academic research in many years with different perceptions, the term “Industry 4.0” is just launched and well accepted to some extend not only in academic life but also in the industrial society as well. While academic research focuses on understanding and defining the concept and trying to develop related systems, business models and respective methodologies, industry, on the other hand, focuses its attention on the change of industrial machine suits and intelligent products as well as potential customers on this progress. It is therefore important for the companies to primarily understand the features and content of the Industry 4.0 for potential transformation from machine dominant manufacturing to digital manufacturing. In order to achieve a successful transformation, they should clearly review their positions and respective potentials against basic requirements set forward for Industry 4.0 standard. This will allow them to generate a well-defined road map. There has been several approaches and discussions going on along this line, a several road maps are already proposed. Some of those are reviewed in this paper. However, the literature clearly indicates the lack of respective assessment methodologies. Since the implementation and applications of related theorems and definitions outlined for the 4th industrial revolution is not mature enough for most of the reel life implementations, a systematic approach for making respective assessments and evaluations seems to be urgently required for those who are intending to speed this transformation up. It is now main responsibility of the research community to developed technological infrastructure with physical systems, management models, business models as well as some well-defined Industry 4.0 scenarios in order to make the life for the practitioners easy. It is estimated by the experts that the Industry 4.0 and related progress along this line will have an enormous effect on social life. As outlined in the introduction, some social transformation is also expected. It is assumed that the robots will be more dominant in manufacturing, implanted technologies, cooperating and coordinating machines, self-decision-making systems, autonom problem solvers, learning machines, 3D printing etc. will dominate the production process. Wearable internet, big data analysis, sensor based life, smart city implementations or similar applications will be the main concern of the community. This social transformation will naturally trigger the manufacturing society to improve their manufacturing suits to cope with the customer requirements and sustain competitive advantage. A summary of the potential progress along this line is reviewed in introduction of the paper. It is so obvious that the future manufacturing systems will have a different vision composed of products, intelligence, communications and information network. This will bring about new business models to be dominant in industrial life. Another important issue to take into account is that the time span of this so-called revolution will be so short triggering a continues transformation process to yield some new industrial areas to emerge. This clearly puts a big pressure on manufacturers to learn, understand, design and implement the transformation process. Since the main motivation for finding the best way to follow this transformation, a comprehensive literature review will generate a remarkable support. This paper presents such a review for highlighting the progress and aims to help improve the awareness on the best experiences. It is intended to provide a clear idea for those wishing to generate a road map for digitizing the respective manufacturing suits. By presenting this review it is also intended to provide a hands-on library of Industry 4.0 to both academics as well as industrial practitioners. The top 100 headings, abstracts and key words (i.e. a total of 619 publications of any kind) for each search term were independently analyzed in order to ensure the reliability of the review process. Note that, this exhaustive literature review provides a concrete definition of Industry 4.0 and defines its six design principles such as interoperability, virtualization, local, real-time talent, service orientation and modularity. It seems that these principles have taken the attention of the scientists to carry out more variety of research on the subject and to develop implementable and appropriate scenarios. A comprehensive taxonomy of Industry 4.0 can also be developed through analyzing the results of this review. ; ; ; ; ; (search for similar items in EconPapers)

2020

(110) (external link)

Abstract (text/html)

Access to the full text of the articles in this series is restricted.

This item may be available elsewhere in EconPapers: for items with the same title. BibTeX RIS (EndNote, ProCite, RefMan) HTML/Text This journal article can be ordered from

for this article Journal of Intelligent Manufacturing is currently edited by in Journal of Intelligent Manufacturing from

Bibliographic data for series maintained by Sonal Shukla ( ) and Springer Nature Abstracting and Indexing ( ). | | Browse Econ Literature- Working papers

- Software components

- Book chapters

- JEL classification

More features- Subscribe to new research

RePEc BiblioAuthor registration. - Economics Virtual Seminar Calendar NEW!

Literature review of Industry 4.0 and related technologies- Author & abstract

- 109 Citations

- Related works & more

Corrections(Marmara University Engineering Faculty) Suggested CitationDownload full text from publisher. Follow serials, authors, keywords & more Public profiles for Economics researchers Various research rankings in Economics RePEc GenealogyWho was a student of whom, using RePEc Curated articles & papers on economics topics Upload your paper to be listed on RePEc and IDEAS New papers by emailSubscribe to new additions to RePEc EconAcademicsBlog aggregator for economics research Cases of plagiarism in Economics About RePEcInitiative for open bibliographies in Economics News about RePEc Questions about IDEAS and RePEc RePEc volunteers Participating archivesPublishers indexing in RePEc Privacy statementFound an error or omission? Opportunities to help RePEc Get papers listedHave your research listed on RePEc Open a RePEc archiveHave your institution's/publisher's output listed on RePEc Get RePEc dataUse data assembled by RePEc IEEE Account- Change Username/Password

- Update Address

Purchase Details- Payment Options

- Order History

- View Purchased Documents

Profile Information- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions. To read this content please select one of the options below:Please note you do not have access to teaching notes, industry 4.0 as a data-driven paradigm: a systematic literature review on technologies. Journal of Manufacturing Technology Management ISSN : 1741-038X Article publication date: 21 June 2019 Issue publication date: 24 March 2021 The purpose of this paper is to identify current technologies related to Industry 4.0 and to develop a rationale to enhance the understanding of their functions within a data-driven paradigm. Design/methodology/approachA systematic literature review of 119 papers published in journals included in the Journal Citation Report (JCR) was conducted to identify Industry 4.0 technologies. A descriptive analysis characterizes the corpus, and a content analysis identifies the technologies. The content analysis identified 111 technologies. These technologies perform four functions related to data: data generation and capture, data transmission, data conditioning, storage and processing and data application. The first three groups consist of enabling technologies and the fourth group of value-creating technologies. Results show that Industry 4.0 publications focus on enabling technologies that transmit and process data. Value-creating technologies, which apply data in order to develop new solutions, are still rare in the literature. Research limitations/implicationsThe proposed framework serves as a structure for analysing the focus of publications over time, and enables the classification of new technologies as the paradigm evolves. Practical implicationsBecause the technical side of the new production paradigm is complex and represents an evolving field, managers benefit from a simplified and data-driven approach. The proposed framework suggests that Industry 4.0 should be approached by looking at how data can create value and at what role each technology plays in this task. Originality/valueThe study makes a direct link between Industry 4.0 technologies and the key resource of this revolution, i.e. data. It provides a rationale that not only establishes relationships between technologies and data, but also highlights their roles as enablers or creators of value. Beyond showing the current focus of Industry 4.0 publications, this paper proposes a framework that is useful for tracking the evolution of the paradigm. AcknowledgementsThe authors thank the Research Coordination of the Brazilian Ministry of Education (CAPES), for the financial support received to conduct this research (PDSE Process No. 88881.187062/2018-01). Klingenberg, C.O. , Borges, M.A.V. and Antunes Jr, J.A.V. (2021), "Industry 4.0 as a data-driven paradigm: a systematic literature review on technologies", Journal of Manufacturing Technology Management , Vol. 32 No. 3, pp. 570-592. https://doi.org/10.1108/JMTM-09-2018-0325 Emerald Publishing Limited Copyright © 2019, Emerald Publishing Limited Related articlesAll feedback is valuable. Please share your general feedback Report an issue or find answers to frequently asked questionsContact Customer Support - DOI: 10.1016/j.jclepro.2024.143023

- Corpus ID: 270747046

Industry 4.0 technologies for sustainability within small and medium enterprises: A systematic literature review and future directions- André de Mendonça Santos , Ângelo Márcio Oliveira Sant’Anna

- Published in Journal of Cleaner Production 1 June 2024

- Environmental Science, Business, Engineering

82 ReferencesInvestigating digital technologies’ implementation in circular businesses: evidence from the going circular path, significance of industry 4.0 technologies in major work functions of manufacturing for sustainable development of small and medium‐sized enterprises, is this time different how industry 4.0 affects firms’ labor productivity, industry 4.0 as an enabler of circular economy practices: evidence from european smes, artificial intelligence-driven supply chain resilience in vietnamese manufacturing small- and medium-sized enterprises, unveiling the relationship between sustainable development and industry 4.0: a text mining literature analysis, developing an iot framework for industry 4.0 in malaysian smes: an analysis of current status, practices, and challenges, do we consider sustainability when we measure small and medium enterprises’ (smes’) performance passing through digital transformation, adoption of information and digital technologies for sustainable smart manufacturing systems for industry 4.0 in small, medium, and micro enterprises (smmes), machine learning algorithms applied to intelligent tyre manufacturing, related papers. Showing 1 through 3 of 0 Related Papers Insights from Deploying Industry 4.0 Technologies Toward Sustainable Business Performance: A Study Based on Applied Methodology of SLR- Conference paper

- First Online: 01 July 2024

- Cite this conference paper

- Pritesh Shukla ORCID: orcid.org/0009-0009-1857-1956 12 ,

- Kumar Rohit ORCID: orcid.org/0000-0003-3349-3799 12 ,

- Avadhesh Dalpati ORCID: orcid.org/0000-0003-0909-4990 12 &

- Ramesh Chandra Gupta ORCID: orcid.org/0000-0002-6545-6362 12

Part of the book series: Lecture Notes in Networks and Systems ((LNNS,volume 995)) Included in the following conference series: - International conference on soft computing for problem-solving

This research focuses on the applicability of Industry 4.0 (I 4.0) technologies exploring their relevance to sustainable business performance. A study was conducted to portray the impact of I 4.0 technologies underlining their effects on business operations. This research aims to determine the linkage between I 4.0 applications and sustainable business performance addressing the barriers to I 4.0 deployment in the context of Indian manufacturing industries. Previous research indicates that sustainable business performance can be categorized into environmental performance, operational performance, and economic performance. On the other hand, Industry 4.0 implementation can be evaluated by finding the crucial enablers and barriers. In this study, a systematic literature review was performed on 68 primary articles published in the year ranging from 2015 to 2022 accumulating crucial insights from diverse publication database repositories. The findings of this article will determine the linkage between “Industry 4.0 deployment” and “sustainable business performance” based on crucial inferences from this study contributing valuable and vital insights into the current research, potential future studies, and key managerial implications in this study domain. This is a preview of subscription content, log in via an institution to check access. Access this chapterSubscribe and save. - Get 10 units per month

- Download Article/Chapter or Ebook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout Purchases are for personal use only Institutional subscriptions Niemeyer JF, Rudolf S, Kvaratskhelia L, Mennenga M, Herrmann C (2022) A creativity-driven case-based reasoning approach for the systematic engineering of sustainable business models. In: 29th CIRP conference on life cycle engineering Google Scholar Beier G, Matthess M, Guan T, Grudzien DI, Xue B, de Lima EP, Chen L (2022) Impact of Industry 4.0 on corporate environmental sustainability: comparing practitioners’ perceptions from China, Brazil and Germany. Sustain Prod Consumption 287–300 Muhmad SN, Muhamad R (2020) Sustainable business practices and financial performance during pre- and post-SDG adoption periods: a systematic review. J Sustain Finance & Invest Stock GST (2016) Opportunities of sustainable manufacturing in Industry 4.0. In: 13th global conference on sustainable manufacturing Lopes de Sousa Jabbour AB, Jabbour CJ, Godinho Filho M, Roubaud D (2018) Industry 4.0 and the circular economy: a proposed research agenda and original roadmap for sustainable operations. Big data analytics in operations & supply chain management Jamwal A, Agrawal R, Sharma M, Kumar V, Kumar S (2021) Developing a sustainability framework for Industry 4.0. In: 28th CIRP conference on life cycle engineering Kumar P, Singh RK, Kumar V (2021) Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: analysis of barriers. Resour, Conserv Recycling 1–12 Sun X, Yu H, Solvang WD, Wang Y, Wang K (2022) The application of Industry 4.0 technologies in sustainable logistics: a systematic literature review (2012–2020) to explore future research opportunities. Environ Sci Pollut Res 9560–9591 Grant MJ, Booth A (2009) A typology of reviews: an analysis of 14 review types and associated methodologies. Health Inf Libraries J 91–108 Gunasekaran A, Papadopoulos T, Dubey R, Wamba SF, Childe SJ, Hazen B, Akter S (2016) Big data and predictive analytics for supply chain and organizational performance. J Bus Res 1–8 Ghobakhloo M (2020) Industry 4.0, digitization, and opportunities for sustainability. J Clean Prod 1–21 Luthra S, Mangla SK (2018) Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Safety Environ Protection Bai C, Dallasega P, Orzes G, Sarkis J (2020) Industry 4.0 technologies assessment: A sustainability perspective. Int J Prod Econ Raj A, Dwivedi G, Sharma A, de Sousa Jabbour AB, Rajak S (2019) Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: an inter-country comparative perspective. Int J Prod Econ Dubey R, Gunasekaran A, Childe SJ, Luo Z, Wamba SF, Roubaud D, Foropon C (2018) Examining the role of big data and predictive analytics on collaborative performance. J Clean Prod Haseeb M, Hussain HI, Ślusarczyk B, Jermsittiparsert K (2019) Industry 4.0: a solution towards technology challenges of sustainable business performance. Social Sci Rosa P, Sassanelli C, Urbinati A, Chiaroni D, Terzi S (2020) Assessing relations between circular economy and industry 4.0: a systematic literature review. Int J Prod Res 1–27 Maxim Ruff MW (2020) Industry 4.0 as an enabler of servitization in the plant engineering business: literature review and development of a conceptual research model. In: 3rd international conference on industry 4.0 and smart manufacturing Zulu SL, Zulu E, Chabala M, Chunda N (2022) Drivers and barriers to sustainability practices in the Zambian construction industry. Int J Construct Manage 1–11 Lamé G (2019) Systematic literature reviews: an introduction. In: International conference on, Delft, Netherlands Nightingale A (2009) A guide to systematic. Determining Surgical Efficacy, pp 381–384 Fernando Y, Jabbour CJ, Wah WX (2019) Pursuing green growth in technology firms through the connections between environmental innovation and sustainable business performance: does service capability matter? Resour, Conserv Recycling Cui Y, Liu W, Rani P, Alrasheedi M (2021) Internet of Things (IoT) adoption barriers for the circular economy using Pythagorean fuzzy SWARA-CoCoSo decision-making approach in the manufacturing sector. Technol Forecast Soc Change Weking J, Stocker M, Kowalkiewicz M, Bohm M, Krcmar H (2020) Leveraging industry 4.0—a business model pattern framework. Int J Prod Econ 1–17 Sharma VK, Chandna P, Bhardwaj A (2016) Green supply chain management related performance indicators in agro industry: a review. J Clean Prod 1–31 Tripathi V, Chattopadhyaya S, Mukhopadhyay AK, Sharma S, Singh J, Pimenov DY, Giasin K (2021) An innovative agile model of smart lean–green approach for sustainability enhancement in industry 4.0. J Open Innov Technol 1–20 Narwane VS, Raut RD, Yadav VS, Singh AR (2020) Barriers in sustainable industry 4.0: a case study of the footwear industry. Int J Sustain Eng 1–15 Bag S, Yadav G, Dhamija P, Kataria KK (2021) Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: an empirical study. J Clean Prod Luthra S, Mangla SK, Yadav G (2019) An analysis of causal relationships among challenges impeding redistributed manufacturing in emerging economies. J Clean Prod 1–36 Jayashree S, Reza MN, Malarvizhi CA, Gunasekaran A, Rauf MA (2022) Testing an adoption model for Industry 4.0 and sustainability: a Malaysian scenario. Sustain Prod Consumption 313–330 Sony M (2020) Pros and cons of implementing Industry 4.0 for the organizations: a review and synthesis of evidence. Prod Manuf Res 244–272 Rajput S, Singh SP (2019) Industry 4.0—challenges to implement circular economy. Benchmarking: Int J Chauhan C, Singh A (2019) A review of Industry 4.0 in supply chain management studies. J Manuf Technol Manage Rajput S, Singh SP (2019) Connecting circular economy and industry 4.0. Int J Inf Manage 98–113 Kumar S, Suhaib M, Asjad M (2020) Narrowing the barriers to industry 4.0 practices through PCA-Fuzzy AHP-K means. J Adv Manage Res Kamble S, Gunasekaran A, Dhone NC (2020) Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int J Prod Res 1–20 Caiado RG, Scavarda LF, Azevedo BD, de Mattos Nascimento DL, Quelhas OL (2022) Challenges and benefits of sustainable industry 4.0 for operations and supply chain management—a framework headed toward the 2030 agenda. Sustainability 1–26 Kumar R, Singh RK, Dwivedi YK (2020) Application of industry 4.0 technologies in SMEs for ethical and sustainable operations: analysis of challenges. J Clean Prod Kaswan MS, Rathi R (2021) Investigation of life cycle assessment barriers for sustainable development in manufacturing using grey relational analysis and best worst method. Int J Sustain Eng 1–15 Raut RD, Mangla SK, Narwane VS, Gardas BB, Priyadarshinee P, Narkhede BE (2019) Linking big data analytics and operational sustainability practices for sustainable business management. J Clean Prod 10–24 Bag S, Pretorius JH (2022) Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. Int J Organizational Anal Soto-Acosta P, Cismaru DM, Vătămănescu EM, Ciochină RS (2016) Sustainable entrepreneurship in SMEs: a business performance perspective. Sustainability Dafflon B, Moalla N, Ouzrout Y (2021) The challenges, approaches, and used techniques of CPS for manufacturing in Industry 4.0: a literature review. The Int J Adv Manuf Technol Nhamo G, Nhemachena C, Nhamo S (2019) Using ICT indicators to measure readiness of countries to implement industry 4.0 and the SDGs. Environ Econ Policy Stud Sony M, Naik S (2020) Critical factors for the successful implementation of industry 4.0: a review and future research direction. Prod Plan Control 1–18 Harikannan N, Vinodh S, Gurumurthy A (2020) Sustainable industry 4.0—an exploratory study for uncovering the drivers for integration. J Model Manage Javaid M, Haleem A, Singh RP, Suman R (2022) Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain Oper Comput 203–217 Beltrami M, Orzes G, Sarkis J, Sartor M (2021) Industry 4.0 and sustainability: towards conceptualization and theory. J Clean Prod 1–21 Goni FA, Gholamzadeh Chofreh A, Estaki Orakani Z, Klemeš JJ, Davoudi M, Mardani A (2021) Sustainable business model: a review and framework development. Clean Technol Environ Policy Sharma M, Kamble S, Mani V, Sehrawat R, Belhadi A, Sharma V (2021) Industry 4.0 adoption for sustainability in multi-tier manufacturing supply chain in emerging economies. J Clean Prod Cezarino LO, Liboni LB, Oliveira Stefanelli N, Oliveira BG, Stocco LC (2019) Diving into emerging economies bottleneck: industry 4.0 and implications for circular economy. Diving into emerging economies bottleneck Lacasa E, Santolaya JL, Biedermann A (2016) Obtaining sustainable production from the product design analysis. J Clean Prod 1–22 Ejsmont K, Gladysz B, Kluczek A (2020) Impact of industry 4.0 on sustainability—bibliometric literature review. Sustainability1–29 Contador JC, Satyro WC, Contador JL, Spinola MD (2020) Flexibility in the Brazilian industry 4.0: challenges and opportunities. Global J Flexible Syst Manage Reis JS, Espuny M, Nunhes TV, Sampaio NA, Isaksson R, Campos FC, Oliveira OJ (2021) Striding towards sustainability: a framework to overcome challenges and explore opportunities through industry 4.0. Sustainability1–28 Gupta H, Kumar A, Wasan P (2021) Industry 4.0, cleaner production and circular economy: an integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. J Clean Prod 1–18 Yadav G, Luthra S, Jakhar SK, Mangla SK, Rai DP (2020) A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: an automotive case. J Clean Prod 2–15 Rad FF, Oghazi P, Palmié M, Chirumalla K, Pashkevich N, Patel PC, Sattari S (2022) Industry 4.0 and supply chain performance: a systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Indus Market Manage 268–293 Nara EO, da Costa MB, Baierle IC, Schaefer JL, Benitez GB, do Santos LM, Benitez LB (2021) Expected impact of industry 4.0 technologies on sustainable development: a study in the context of Brazil’s plastic industry. Sustain Prod Consumption 102–122 Machado E, Scavarda LF, Caiado RG, Thomé AM (2021) Barriers and enablers for the integration of industry 4.0 and sustainability in supply chains of MSMEs. Sustainability1–31 Seth D (2016) An empirical investigation of critical success factors and performance measures for green manufacturing in cement industry. J Manuf Technol Manage Mio C, Costantini A, Panfilo S (2021) Performance measurement tools for sustainable business: a systematic literature review on the sustainability balanced scorecard use. Corporate Soc Responsibility Environ Manage 367–384 Castagnoli R, Büchi G, Coeurderoy R, Cugno M (2021) Evolution of industry 4.0 and international business: a systematic literature. Eur Manage J 1–18 Machado CG, Winroth M, Carlsson D, Almström P, Centerholt V, Hallin M (2019) Industry 4.0 readiness in manufacturing companies: challenges and enablers towards increased digitalization. In: 52nd CIRP conference on manufacturing systems Pasi BN, Mahajan SK, Rane SB (2021) The current sustainability scenario of industry 4.0 enabling technologies in Indian manufacturing industries. Industry 4.0 Enabling Technol 1–32 Kayapinar Kaya S, Aycin E (2021) An integrated interval type 2 fuzzy AHP and COPRAS-G methodologies for supplier selection in the era of industry 4.0. Neural Comput Appl 10515–10535 Khanzode AG, Sarma PR, Mangla SK, Yuan H (2020) Modeling the industry 4.0 adoption for sustainable production in micro, small & medium enterprises. J Clean Prod Ullah H, Wang Z, Mohsin M, Jiang W, Abbas H (2022) Multidimensional perspective of green financial innovation between green intellectual capital on sustainable business: the case of Pakistan. Environ Sci Pollut Res Yadav G, Kumar A, Luthra S, Garza-Reyes JA, Kumar V, Batista L (2020) A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers. Comput Industry 1–13 Download references Author informationAuthors and affiliations. Department of Industrial and Production Engineering (IPE), SGSITS, Indore, MP, India Pritesh Shukla, Kumar Rohit, Avadhesh Dalpati & Ramesh Chandra Gupta You can also search for this author in PubMed Google Scholar Corresponding authorCorrespondence to Pritesh Shukla .  Editor informationEditors and affiliations. Department of Applied Mathematics and Scientific Computing, IIT Roorkee, Roorkee, Uttarakhand, India Millie Pant Department of Mathematics, Indian Institute of Technology Roorkee, Roorkee, India School of Mathematics, Computer Science and Engineering, Liverpool Hope University, LIVERPOOL, UK Atulya Nagar Rights and permissionsReprints and permissions Copyright information© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd. About this paperCite this paper. Shukla, P., Rohit, K., Dalpati, A., Gupta, R.C. (2024). Insights from Deploying Industry 4.0 Technologies Toward Sustainable Business Performance: A Study Based on Applied Methodology of SLR. In: Pant, M., Deep, K., Nagar, A. (eds) Proceedings of the 12th International Conference on Soft Computing for Problem Solving. SocProS 2023. Lecture Notes in Networks and Systems, vol 995. Springer, Singapore. https://doi.org/10.1007/978-981-97-3292-0_34 Download citationDOI : https://doi.org/10.1007/978-981-97-3292-0_34 Published : 01 July 2024 Publisher Name : Springer, Singapore Print ISBN : 978-981-97-3291-3 Online ISBN : 978-981-97-3292-0 eBook Packages : Intelligent Technologies and Robotics Intelligent Technologies and Robotics (R0) Share this paperAnyone you share the following link with will be able to read this content: Sorry, a shareable link is not currently available for this article. Provided by the Springer Nature SharedIt content-sharing initiative Policies and ethics - Find a journal

- Track your research

Academia.edu no longer supports Internet Explorer. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser . Enter the email address you signed up with and we'll email you a reset link.  Literature review of Industry 4.0 and related technologies 2018, Journal of Intelligent Manufacturing Related PapersSamrudhi Deshmukh The manufacturing industry is a sector of our society which constantly faces challenges with the variation in demand and supply. Optimization in such a dynamic environment becomes difficult for any industry. Advanced approaches constantly attempt to balance the profit of the supplier as well as contentment level of the customer. Automation in the industry assures that mass production will maintain the supply proportional to the demand. In order to take the automation to the next level, Industry 4.0 allows for a more flexible production environment by introducing the concept of digitalization through a cyber-physical system or CPS. It also becomes an attempt to keep the manufacturing sector updated with the advances in technology of this 21st Cy. This article attempts to list out the concepts of this next generation approach towards a more sustainable model of the manufacturing industry. Moreover, the research will also investigate the advantages and limitations of such a concept in ...  International Journal for Research in Applied Science and Engineering Technology IJRASET IJRASET Publication The objective of this paper is to visualize and to show the direction of Industry 4.0 to develop smart factories in future. The application of new techniques and technologies which are based upon the Internet of things (IOT) ,block chain technology, cloud computing and cyber physical system have paved the path of significant improvement such as increase of automation, quality of production and reduced the time between the development of new products and its launch. Ahmed Elkaseer The arrival of Industry 4.0 has popularised the concept of smart interactions between humans and the physical world that could realise the synergistic integration of intelligent manufacturing assets. However, a systematic and cogent approach to the practical and profitable application of Industry 4.0 is still missing. This paper presents practical approaches to the application of Industry 4.0 to manufacture with the aim of strengthening its competitiveness and meeting the growing serious challenges that threaten its profitability and survival. Precision Additive Metal Manufacturing is utilised in this study for demonstration purposes. A conceptual framework combined with two practical modules available in the market, a "native-design" and "Plug and Play", is proposed. These approaches offer flexible prototypes with sequential procedures that ultimately would allow for easy employment of Industry 4.0, and will help remove technical barriers to the development of m... BEATRICE SANTOS The evolution of information and communication technologies and its introduction into production processes are transforming traditional industry, bringing it to a new level of organizational development. In order to avail the benefits of these technologies to strengthen competitiveness in the global market, a new paradigm is being discussed worldwide. Industry 4.0 or 4th Industrial Revolution are some of the terms used to describe the implementation of "smart" devices that can communicate autonomously along the value chain. In this approach, machines use self-optimization, self-configuration, and artificial intelligence to provide better quality goods and services. In this context, the overall goal of the study is to intensify the discussion and provide an overview of Industry 4.0 to show how combination of advanced technologies and internet can create new opportunities to overcome the current industrial challenges. MOHD SUHAIB Received: 25 January 2019 Abstract Accepted: 14 August 2019 Low cost manufacturing of quality products remains an essential part of present economy and technological advances made it possible. Advances and amalgamation of information technology bring the production systems at newer level. Industry 4.0, factory for future, smart factory, digital manufacturing, and industrial automation are the new buzz words of industry stalwarts and academicians. These new technological revolutions bound to change not only the complete manufacturing scenarios but many other sectors of the society. In this paper an attempt has been made to capture the essence of Industry 4.0 by redefining it in simple words, further its complex, disruptive nature and inevitability along with technologies backing it has been discussed. Its enabling role in manufacturing philosophies like Lean Manufacturing, and Flexible Manufacturing are also reported. At last the challenges its adoption and future research areas are ... The Journal of Engineering and Exact Sciences LIZANDRA VERGARA The concept of Industry 4.0 emerged in Germany as a strategy for innovation and recovery of economic performance and has spread worldwide. The digital transformation proposed by Industry 4.0 is driven by intelligent manufacturing processes, digitalization, flexibility, integration of systems, and real-time analysis of big data generating intelligent processes and services oriented to customer needs. However, despite the opportunities produced by technological innovation, the fourth industrial revolution has established an environment of uncertainty in the labor market and business models reflected throughout the social sphere. Thus, this study aimed to identify the potential impacts and challenges of Industry 4.0 through a systematic literature review (SLR). Our findings pointed to seven potential impacts of Industry 4.0 on manufacturing: (i) environmental, (ii) competitive, (iii) economic, (iv) education, (v) labor market, (vi) business models, and (vii) social. Additionally, six p... Renewable and Nonrenewable Energy M.vijaya Lakshmi , Dr. Ramachandran Manickam , Sathiyaraj Chinnasamy , A PAVITHRA Industry 4.0 Wireless Supported by connectivity and sensors Factories has machines. These sensors Display the entire production line and monitor and can make its own decisions are integrated into one system. Industry 4.0 Smart production Uses processes to produce essential waste products to meet the COVID-19 epidemic shortage. Patients need themselves Essential medical supplies to get on time, during this crisis Medical disposable items and Smart supply chain of equipment it provides Industry is 4.0 as a flexible product line Smart system used. Intelligence (I) by RTC, real-time information on Internet of Things (Yoda) and almost all other digital technologies for the entire production process. Any medical area Design and upgrade pre-designed Using software is done quickly and to print the required components Digital production such as 3D printing Uses technologies. Industrial 4.0 Technologies COVID-19Diagnose symptoms of, It is related to this disease Helps to avoid the chances of getting sick Can predict. Possible health problems and expected recovery Helps keep track of opportunities. Govt for 19 explosions Assistive Industry 4.0 Notable Technologies. Cross New Business Opportunities Is open. However, flexibility, Performance and product customization the requirements of Real to handle value creation Procedures no longer apply. Industrial 4.0, (Fourth Industrial Revolution) is a term coined in Germany; more important ideas were first published in 2011.It is the internet of future technologies Physical systems (CPS), Integration in the Internet and production systems as defined. Control computers in real time, Plan and predict Helps. In the field of technology, in the production of this concept causing revolution and related services have been discussed in research for many years. One of the basic principles for creating an industrial 4.0 environment is to connect organizations and Working value chain individually and Control each other arbitrarily. Research Expression is an interdisciplinary biannual and bilingual research journal published by Government VYT Post Graduate Autonomous College Dr. Ashok D . Gaur Technology has changed the face of the industrial and manufacturing world. This is the age of the fourth industrial revolution, commonly known as Industry 4.0. It means the introduction of automation and data exchange in manufacturing technologies like Cyber-Physical Systems, Internet of Things, big data and analytics, augmented reality, additive manufacturing, simulation, horizontal and vertical system integration, autonomous robots as well as cloud computing. It links between man and machine by integrating and combining artificial intelligence in machines. The main aims of Industry 4.0 to initiate transformation in industrial manufacturing through digitalization and exploitation of the potentials of new technologies. In essence, Industry 4.0 is related to the creation of creates "smart factory". Amazon, Uber, Facebook, "smart factories" and 3D printing, are among modern pioneers of the new industrial revolution. But with a great opportunity, comes great challenges. The aim of this paper is to present and facilitate an understanding of Industry 4.0 concepts, its drivers, enablers, goals, and limitations. Sarah El Hamdi The industrial sector has historically been linked to the prosperity, development and evolution of nations, hence to the genesis of the philosophy of competitiveness, mainly at the manufacturing level. An environment is in perpetual adaptation to trends, and the best example is the change of industrial ideology, as was the case in the past. The global society is facing the same challenges. Customer demands are becoming more and more specific and personalized, which means that factories have to innovate in terms of production and management of mudas in an eco-environmental context closely followed by several global organizations. Information and communication technologies have become the joker to master in order to stay in a market that is global and very competitive. At the heart of this evolution is the emergence of the Industry 4.0 concept, which includes a key element that is intelligent production in factories of the future that can meet different obstacles. The purpose of the c... Industry 4.0 - Current Status and Future Trends Ercan Oztemel Loading Preview Sorry, preview is currently unavailable. You can download the paper by clicking the button above. RELATED PAPERSIOP Conference Series: Earth and Environmental Science Shahryar Sorooshian Belmont Press Dr.adel aneiba Annual Reviews in Control Hervé Panetto International Journal of Online Engineering (iJOE) juan david diaz IntechOpen Limited - London Meisam Gordan International Journal of Scientific Research in Science and Technology International Journal of Scientific Research in Science and Technology IJSRST Mobility and Vehicle Mechanics edina karabegovic Dimitrios Koulouriotis THE IJES Editor Zenodo (CERN European Organization for Nuclear Research) RACH MERVEILLE Journal of Intelligent Manufacturing Ahmad Barari IFAC-PapersOnLine Václav Kaczmarczyk IJAERS Journal IRJET Journal , Dr. Surabhi shanker IRJET Journal Technical, Economic and Societal Effects of Manufacturing 4.0 karl-erik michelsen GIS SCIENCE JOURNAL shimol philip Aparna Unnikrishnan RELATED TOPICS- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Login to your accountChange password, your password must have 8 characters or more and contain 3 of the following:. - a lower case character,

- an upper case character,

- a special character

Password Changed SuccessfullyYour password has been changed Create a new accountCan't sign in? Forgot your password? Enter your email address below and we will send you the reset instructions If the address matches an existing account you will receive an email with instructions to reset your password Request UsernameCan't sign in? Forgot your username? Enter your email address below and we will send you your username If the address matches an existing account you will receive an email with instructions to retrieve your username  - This Journal

-

- Institutional Access

Cookies NotificationOur site uses javascript to enchance its usability. you can disable your ad blocker or whitelist our website www.worldscientific.com to view the full content., select your blocker:, adblock plus instructions. - Click the AdBlock Plus icon in the extension bar

- Click the blue power button

- Click refresh

Adblock Instructions- Click the AdBlock icon

- Click "Don't run on pages on this site"

uBlock Origin Instructions- Click on the uBlock Origin icon in the extension bar

- Click on the big, blue power button

- Refresh the web page

uBlock Instructions- Click on the uBlock icon in the extension bar

Adguard Instructions- Click on the Adguard icon in the extension bar

- Click on the toggle next to the "Protection on this website" text

Brave Instructions- Click on the orange lion icon to the right of the address bar

- Click the toggle on the top right, shifting from "Up" to "Down

Adremover Instructions- Click on the AdRemover icon in the extension bar

- Click the "Don’t run on pages on this domain" button

- Click "Exclude"

Adblock Genesis Instructions- Click on the Adblock Genesis icon in the extension bar

- Click on the button that says "Whitelist Website"

Super Adblocker Instructions- Click on the Super Adblocker icon in the extension bar

- Click on the "Don’t run on pages on this domain" button

- Click the "Exclude" button on the pop-up

Ultrablock Instructions- Click on the UltraBlock icon in the extension bar

- Click on the "Disable UltraBlock for ‘domain name here’" button

Ad Aware Instructions- Click on the AdAware icon in the extension bar

- Click on the large orange power button

Ghostery Instructions- Click on the Ghostery icon in the extension bar

- Click on the "Trust Site" button

Firefox Tracking Protection Instructions- Click on the shield icon on the left side of the address bar

- Click on the toggle that says "Enhanced Tracking protection is ON for this site"

Duck Duck Go Instructions- Click on the DuckDuckGo icon in the extension bar

- Click on the toggle next to the words "Site Privacy Protection"

Privacy Badger Instructions- Click on the Privacy Badger icon in the extension bar

- Click on the button that says "Disable Privacy Badger for this site"

Disconnect Instructions- Click on the Disconnect icon in the extension bar

- Click the button that says "Whitelist Site"

Opera Instructions- Click on the blue shield icon on the right side of the address bar

- Click the toggle next to "Ads are blocked on this site"

System Upgrade on Tue, May 28th, 2024 at 2am (EDT)Artificial intelligence applications for industry 4.0: a literature-based study. - Mohd Javaid ,

- Abid Haleem ,

- Ravi Pratap Singh , and

- Rajiv Suman

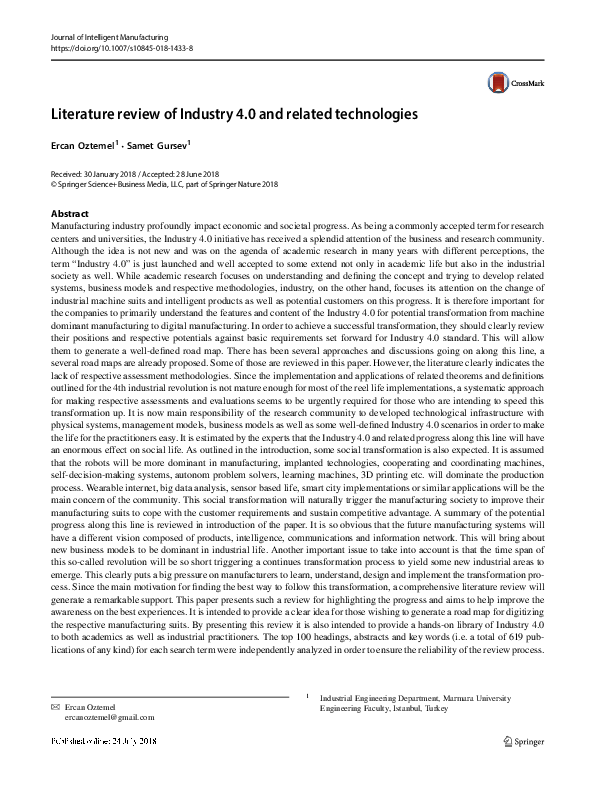

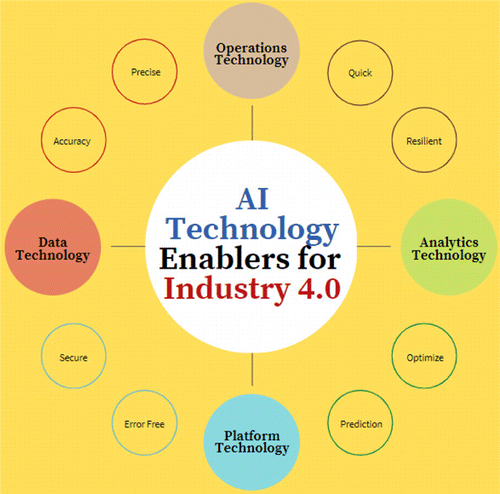

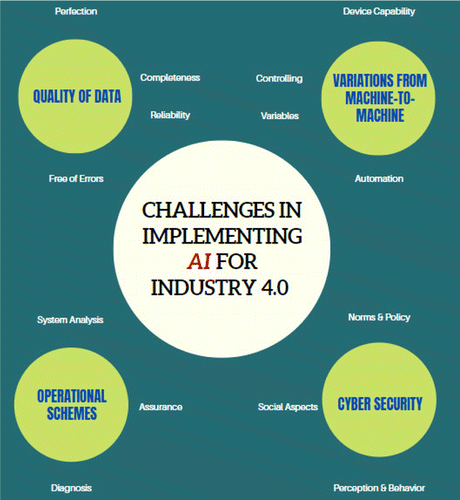

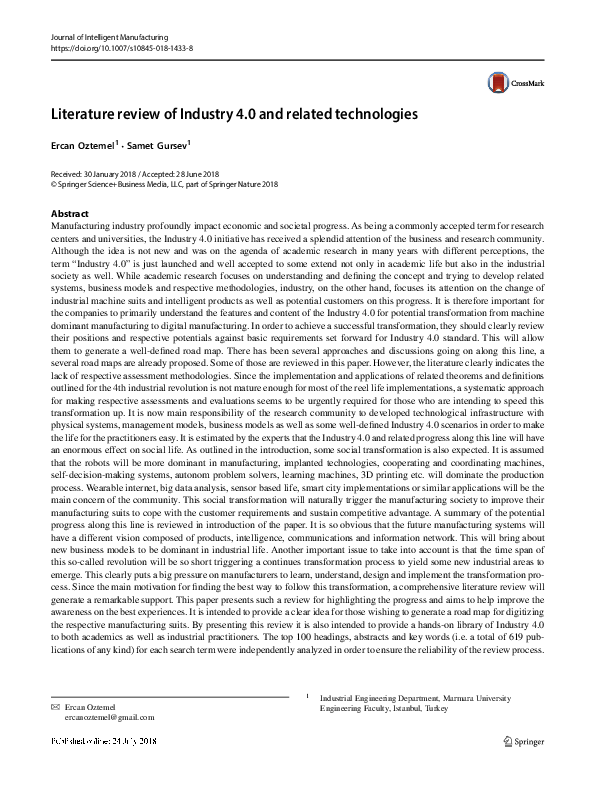

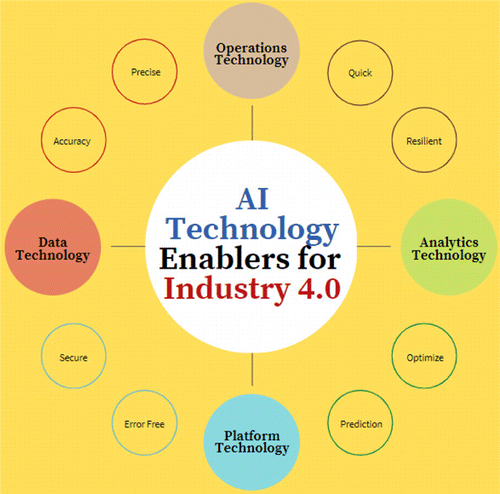

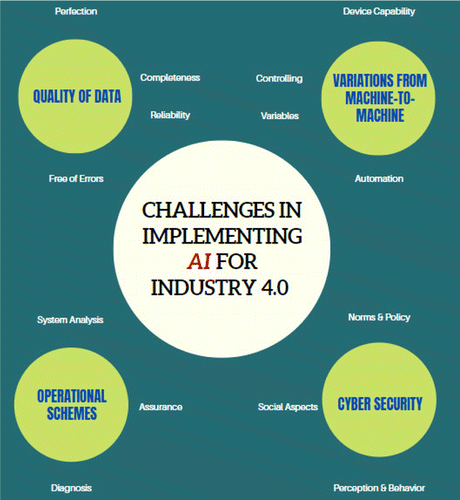

https://orcid.org/0000-0001-8871-2886 Department of Mechanical Engineering, Jamia Millia Islamia, New Delhi, India E-mail Address: [email protected] Corresponding author. Search for more papers by this author https://orcid.org/0000-0002-3487-0229 Department of Industrial and Production Engineering, Dr B R Ambedkar National Institute of Technology, Jalandhar, Punjab, India Department of Industrial and Production Engineering, G. B. Pant University of Agriculture and Technology, Pantnagar, Uttarakhand, India Artificial intelligence (AI) contributes to the recent developments in Industry 4.0. Industries are focusing on improving product consistency, productivity and reducing operating costs, and they want to achieve this with the collaborative partnership between robotics and people. In smart industries, hyperconnected manufacturing processes depend on different machines that interact using AI automation systems by capturing and interpreting all data types. Smart platforms of automation can play a decisive role in transforming modern production. AI provides appropriate information to take decision-making and alert people of possible malfunctions. Industries will use AI to process data transmitted from the Internet of things (IoT) devices and connected machines based on their desire to integrate them into their equipment. It provides companies with the ability to track their entire end-to-end activities and processes fully. This literature review-based paper aims to brief the vital role of AI in successfully implementing Industry 4.0. Accordingly, the research objectives are crafted to facilitate researchers, practitioners, students and industry professionals in this paper. First, it discusses the significant technological features and traits of AI, critical for Industry 4.0. Second, this paper identifies the significant advancements and various challenges enabling the implementation of AI for Industry 4.0. Finally, the paper identifies and discusses significant applications of AI for Industry 4.0. With an extensive review-based exploration, we see that the advantages of AI are widespread and the need for stakeholders in understanding the kind of automation platform they require in the new manufacturing order. Furthermore, this technology seeks correlations to avoid errors and eventually to anticipate them. Thus, AI technology is gradually accomplishing various goals of Industry 4.0. - Artificial intelligence (AI)

- Industry 4.0

- applications

- advancements

1. IntroductionThe applications of artificial intelligence (AI) technologies enhance the capabilities significantly in the manufacturing sector as it works across various business lines and levels, from staff planning to product design, maximizing performance, product quality and employee well-being. Advances in AI are central to various advancements, allowing robots to manage more computational tasks and make independent decisions based on environmental data in real time for Industry 4.0. It includes managing different criteria such as content types, manufacturing methods, budget limits and time constraints. The ideas and other essential tasks can be managed and evaluated using machine learning (ML), providing further insight into the latest designs. AI is used in factories to allow the predictive management of sensitive industrial machineries to predict asset failure in Industry 4.0. The administration is helped to timely rehabilitate the facilities to avoid expensive unplanned downtime ( Yao et al. , 2017 ; Lee et al. , 2018 ; Bécue et al. , 2021 ). AI algorithms help businesses to predict shifts in the markets to maximize production supply chains. This offers management an enormous benefit from a reactionary to a competitor. AI algorithms estimate market demands by searching for position trends, socio-economic and macroeconomic variables, environmental patterns, status policy, customer behavior and more. This development would allow manufacturers to reduce production downtime and optimize their manufacturing lines’ overall operating effectiveness. In addition, AI and computer training increase quality management and standardization by producing a predictive analysis of the equipment’s features and streamlining production lines ultimately. With AI implementation, industries can now take fast, data-driven decisions, simplify production processes, minimize operating costs and enhance customer service ( Dal Mas et al. , 2019 ; Haenlein et al. , 2019 ; Gupta et al. , 2021 ). With an AI-compatible smart plant, manufacturing will work unprecedentedly, reduce costs and improve customer service. Industries can avoid downtimes by forecasting delays, control inventory by tracking stocks, anticipate the delivery speed and provide the highest quality goods. In order to monitor the production process and detect mistakes such as the microscopic crack in production facilities, computing vision may be used. AI may alert companies to production line problems that may lead to quality problems. The serious ones can be avoided in the early stages of the overall development level of Industry 4.0 ( Javaid and Haleem , 2019 ; Ibrahim and Hassan , 2019 ; Sanchez et al. , 2020 ). Advanced AI algorithms in deep learning and artificial neural networks are used for repair prediction to formulate asset failure predictions. Quality requires AI algorithms to report evolving production defects to manufacture teams that can trigger product quality problems. This can analyze slight machine behavior abnormalities, changes in raw materials, etc. In order to ensure that a maximum algorithm produces values within the given interval, the product designer often establishes minimum and maximum limits. The results given are solutions that can be evaluated further with the help of ML to obtain insights into which architecture satisfies standards. AI algorithms are used for quality management to alert production units of possible production faults, leading to problems with product quality ( Cheng et al. , 2016 ; Koh et al. , 2019 ; Bousdekis et al. , 2020 ). Manufacturing industries use this technology to produce a virtual representation that replicates factory, product or physical characteristics. By using cameras, sensors and other data collection techniques, this reflects real-time knowledge. Combining interactive and physical environments makes it possible to track plants, analyze data and solve issues proactively. The flaw detecting method in production lines becomes smarter in manufacturing. A computerized device can detect various surface defects such as scratches, cracks and leaks and others with deep neural network integrations. Data scientists teach visual inspection systems to identify defects according to their mission by applying image recognition, object identification and instance segmentation algorithms ( Haleem et al. , 2020 ; Massaro et al. , 2020 ). ML modeling will forecast energy demand in the future by handling historical data on consumed energy. The popular ML method is focused on sequential data measurements to forecast energy consumption. AI can permit systems to monitor themselves to reduce downtimes, maximize resource uses and anticipate failures ( Mazurek and Małagocka , 2019 ; Chen et al. , 2020 ). It can aid decision-makers in testing environments, increase the efficiency of assets and prevent system failures. It will help organizations appreciate their products by visualizing the performance of their products in their factory environment and in real time by the workforce. The information obtained from the simulated reality will be used to turn the product concept into potential goods in the real universe ( Bortolini et al. , 2017 ; Milward et al. , 2019 ). 2. Research MethodThis is review-based research reporting from different research papers, blogs and other research platforms by searching the keyword as “artificial intelligence”, “Industry 4.0”. This paper addresses the following research objectives: | • | To brief about AI for Industry 4.0 and discuss technological features and traits of AI for Industry 4.0; | | • | To study significant advancements of AI and discuss various challenges in implementing the AI concept for Industry 4.0; | | • | To study diversified sets/subsets of AI for Industry 4.0; | | • | To identify significant applications of AI for Industry 4.0. |