Lean Six Sigma Training Certification

- Facebook Instagram Twitter LinkedIn YouTube

- (877) 497-4462

Lean Six Sigma A3 Process Keeps Problem Solving Organized

December 18th, 2017

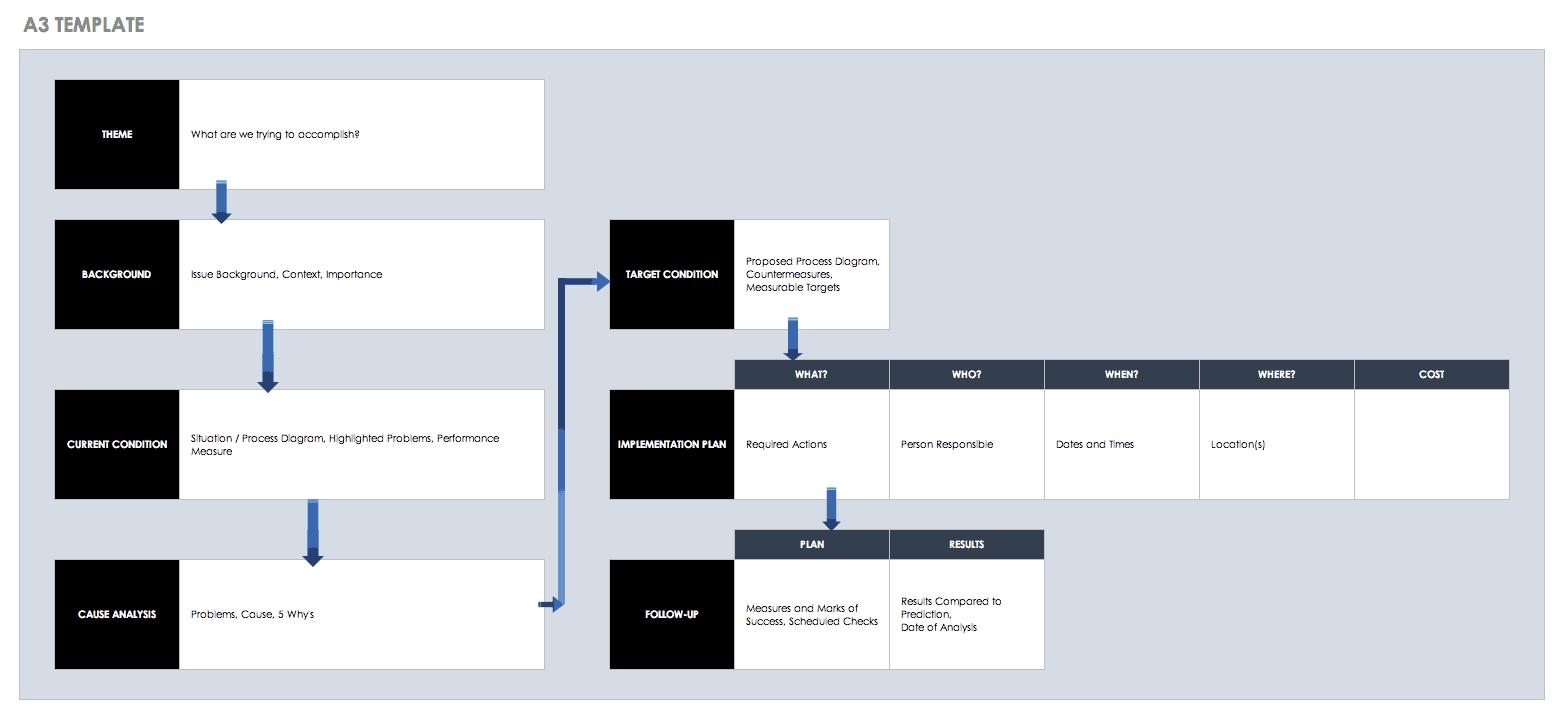

When problem-solving, staying in an organized systematic path is extremely important, otherwise, new issues could arise. That’s why the Lean Six Sigma approach called A3 is so genius. Basically, the A3 process is a structured template for solving problems in a continuous matter.

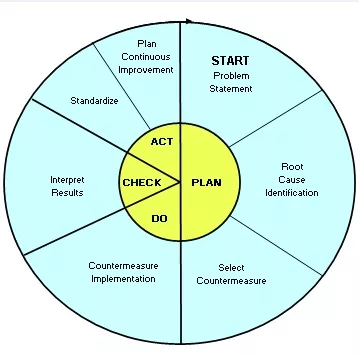

The A3 approach is also known as SPS, which stands for Systematic Problem Solving. This approach is based on the principles of PDCA (Plan, Do Check, Act).

The reason for the A3 approach is to provide structure to problem-solving and helps determine what caused the problem.

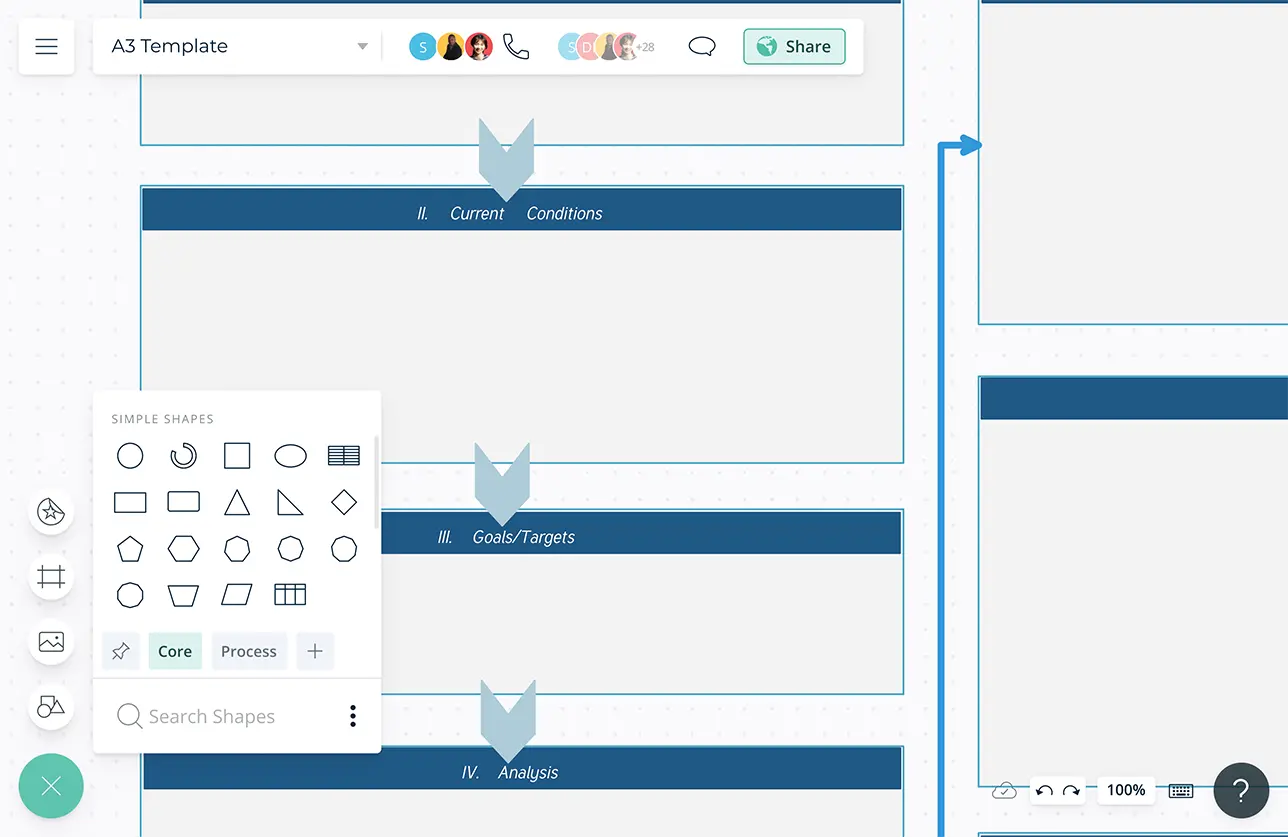

(Systematic Problem Solving) A3 Process of Problem Solving

Background :.

Select an issue you want to resolve. State how this issue impacts your business, your customers, and processes, and of course your bottom line or financials.

Problem Statement :

Make a detailed statement of the issue. Quantify the exact issue and define detailed specifics so that the impact of the issue is communicated to others.

Goal Statement:

Make a goal statement and what you want to accomplish by taking on this A3 project. You can map out what exact goals you will accomplish. Include timeframe for accomplishing this goal.

Root Cause Analysis :

Conduct a thorough analysis as to what might be causing this particular issue.

Countermeasures:

These are the steps that you are going to take to make the necessary changes. Make sure you are addressing the root causes that you have found.

Develop the New Target State:

Illustrate how you will address the root causes of the issue. You will use a diagram on how the newly proposed process will work. When communicating your countermeasures, make sure you note the projected or expected improvements.

Implementation Plan:

This is your well-thought-out workable plan. Include a list of actions that need to get done so that the countermeasures can take place and improvement can be obtained.

Follow-up Plan:

This is to make sure that the target goal was met. Check on it at a regularly scheduled time to make sure the target has been met.

Discuss with Affected Parties:

You must communicate all changes to those it affected and see how the progress has improved. Here is where concerns should be addressed if there are any.

Get Approval:

Make sure everyone is on board with the new plan.

Implementation:

Execute the new implementation plan.

Evaluate the Results:

Measure the results and make sure you hit your goal if you haven’t hit it.

Your goal is to then repeat the implementation plan until the goal is met.

Afterthought

Problem-solving is a routine chore that businesses need to deal with to cut profit margins. Systematic Problem Solving (the A3 process) introduces concepts of project definition, development of root cause, and implementation of the solution, allowing you a way to achieve successful business transformation.

For more information on our Six Sigma training courses or services, please visit 6sigma.us .

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs

SixSigma.us Accreditation & Affiliations

Monthly Management Tips

- Be the first one to receive the latest updates and information from 6Sigma

- Get curated resources from industry-experts

- Gain an edge with complete guides and other exclusive materials

- Become a part of one of the largest Six Sigma community

- Unlock your path to become a Six Sigma professional

" * " indicates required fields

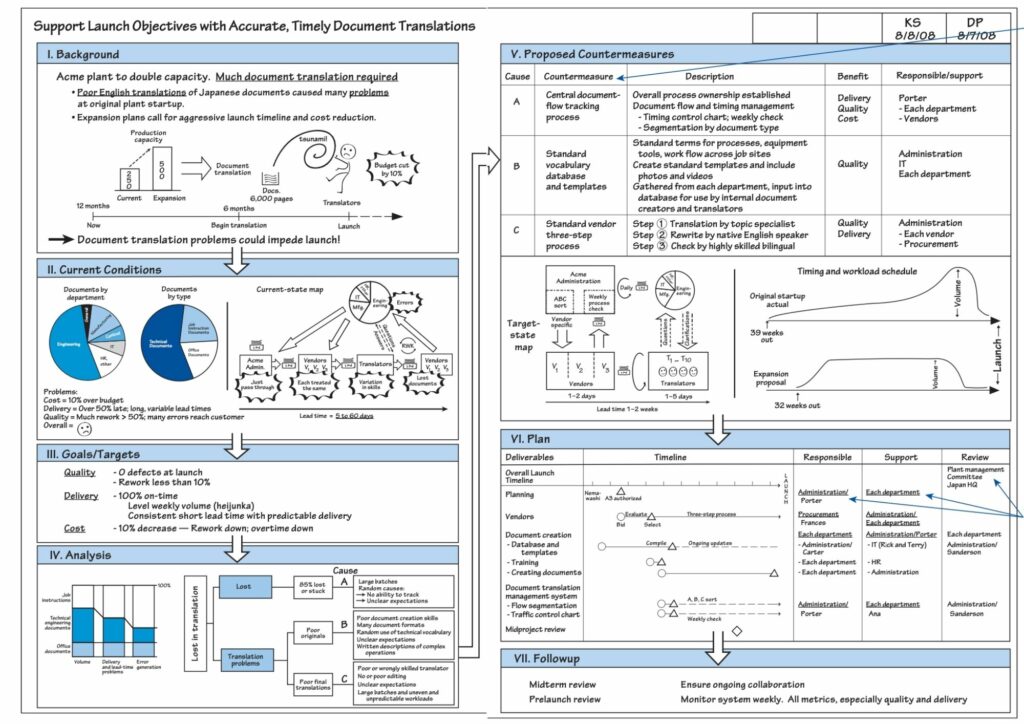

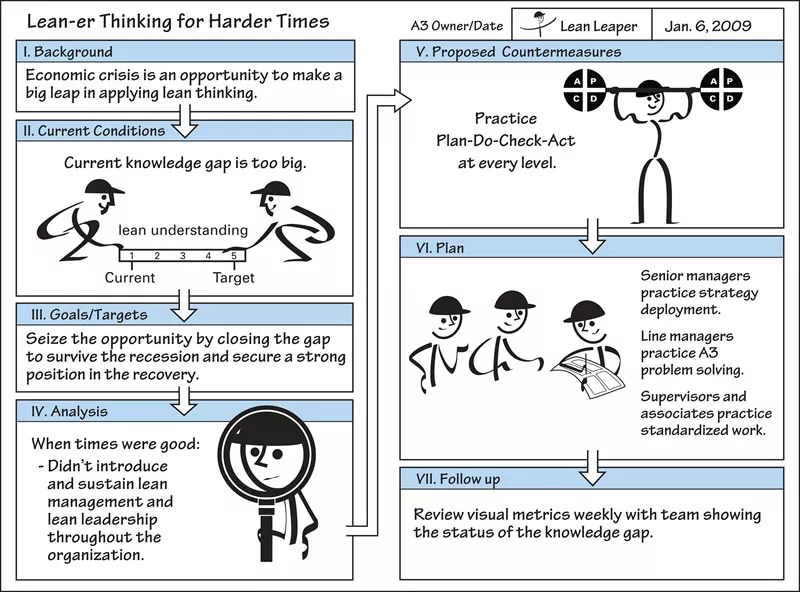

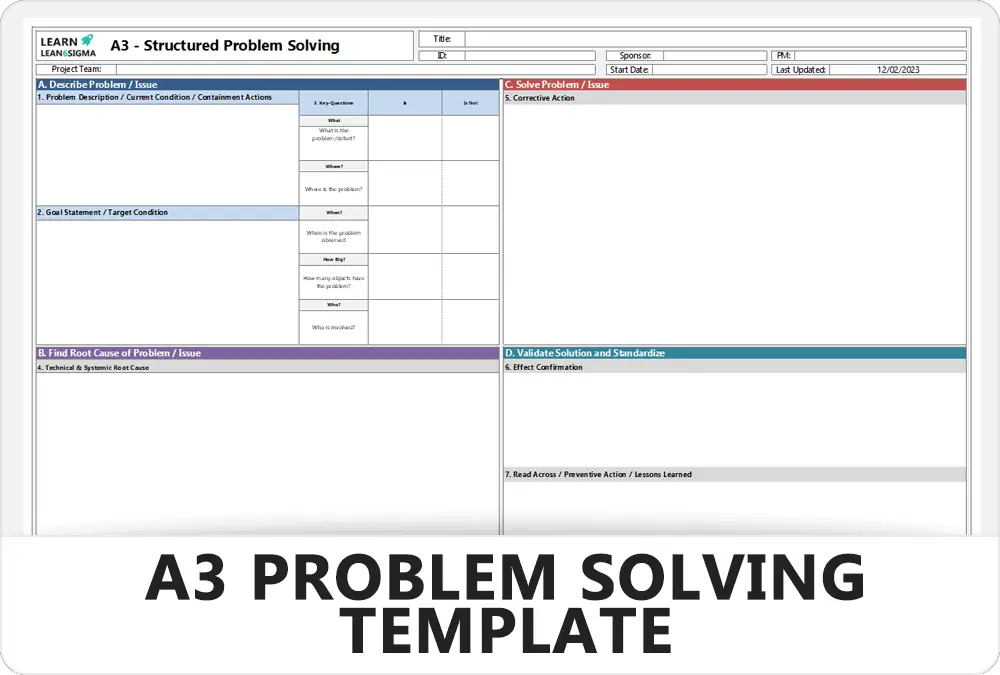

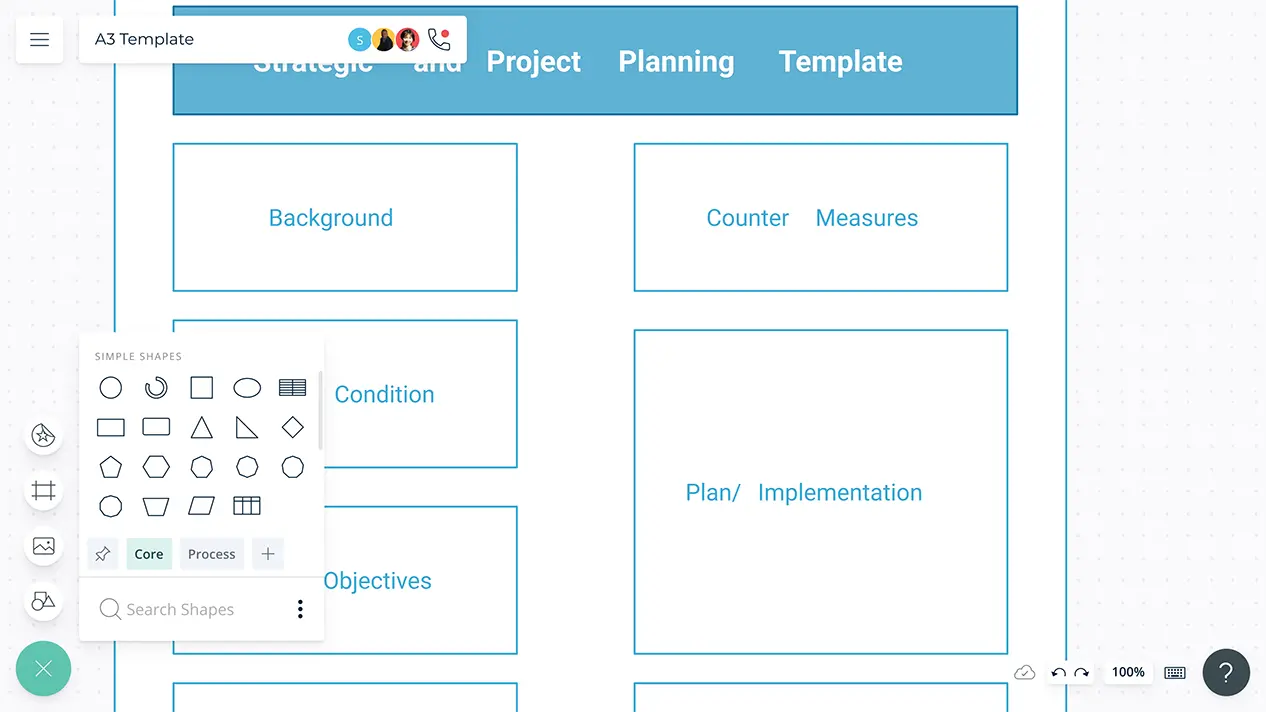

An A3 Report is a Toyota-pioneered practice of getting the problem, the analysis, the corrective actions, and the action plan down on a single sheet of large (A3) paper, often with the use of graphics. At Toyota, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

But it is much more than a sheet a paper with facts and figures. It is a management process learned through dialogue about concrete problems. It does this by means of a dialogue between a lean manager and a subordinate who learns lean management and leadership as she solves an important problem.

This process of solving problems while creating better employees—A3 analysis—is core to the Toyota management system. An A3 report guides the dialogue and analysis. It identifies the current situation, the nature of the issue, the range of possible counter- measures, the best countermeasure, the means (who will do what when) to put it into practice, and the evidence that the issue has actually been addressed.

The lean leader’s job is to develop people. If the worker hasn’t learned, the teacher hasn’t taught. Training Within Industry Report (Washington, DC: War Manpower Commission, Bureau of Training, 1945).

Effective use of the A3 process can facilitate the shift from a debate about who owns what (an authority-focused debate) to a dialogue around what is the right thing to do (a responsibility-focused conversation). This shift has a radical impact on the way decisions are made. Individuals earn the authority to take action through the manner in which they frame the issue. They form consensus and get decisions made by focusing relentlessly on indisputable facts that they and their peers derive from the gemba.

As a result, A3 management can best be understood as neither “top-down” nor “bottom-up.” The process clarifies responsibility by placing ownership squarely on the shoulders of the author-owner of the A3, the individual whose initials appear in the upper right-hand corner of the paper. This person may not have direct authority over every aspect of the proposal. Yet this owner is clearly identified as the person who has taken or accepted responsibility to get decisions made and implemented .

Example A3s

The Many Facets of A3

- A standard paper size: At its most fundamental, “A3” is the international term for a sheet of paper 297 millimeters wide and 420 millimeters long. The closest U.S. paper size is the 11-by-17-inch tabloid sheet.

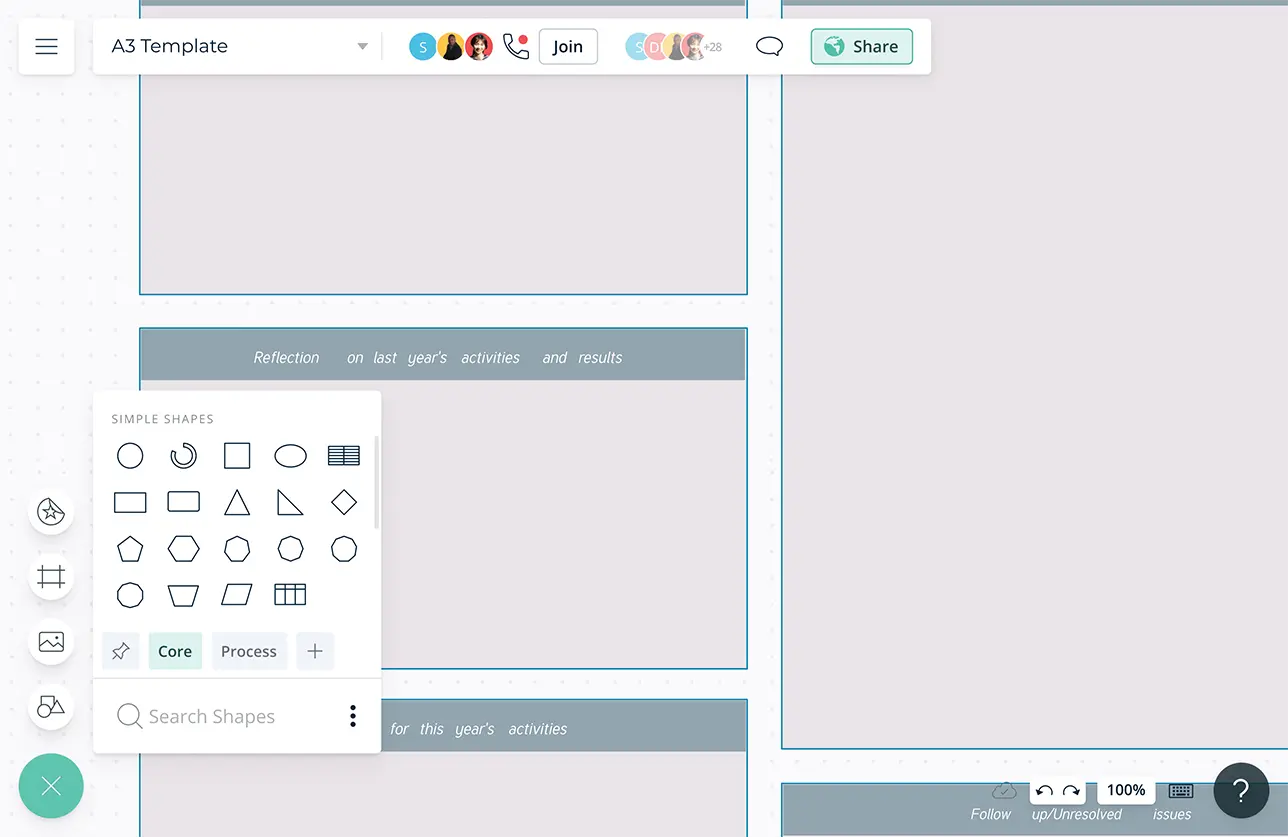

- A template: Many companies and individuals use an A3-sized document pre-printed with the steps needed to conduct lean problem-solving or improvement efforts, with generous white space for “A3 owners” to record their progress. While they refer to this document as a template, an “A3” is not a template.

- A storyboard: As users record their problem-solving or improvement project’s progress, the A3 becomes a storyboard used to facilitate communication, collaboration, and coordination with other stakeholders affected by the goal the A3 owner is working toward (e.g., solving a problem or improving a process ). By having all the facts about the effort in one place, logically presented and summarized, the A3 owner is better able to gain buy-in from other stakeholders for recommended process changes.

- A report: Once the A3 problem-solving effort concludes, the A3 storyboard serves as a report of the problem-solving or improvement initiative, including the facts and data gathered, hypotheses considered, countermeasures tried, experiment results, corrective actions taken, and the overall thinking of the A3 owner and stakeholders. At Toyota and elsewhere, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

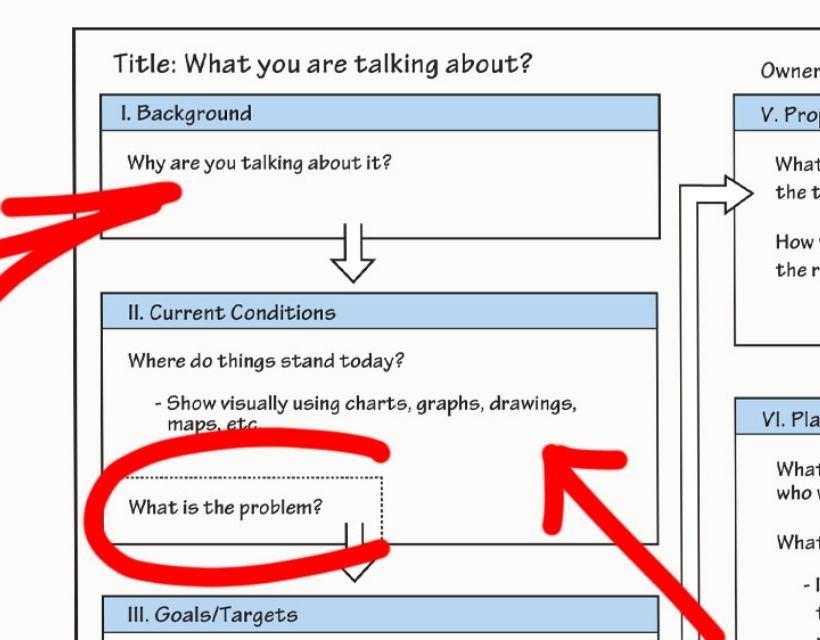

- A problem-solving methodology (or process): Most lean practitioners know “the A3” as a problem-solving process guided by specific steps or questions. The left side of the A3 focuses on various elements of the problem or current condition, and the right on the countermeasures considered, tested, and chosen that resolves the issue or creates a higher standard.

- A management discipline (or process): At a higher level, lean leaders, managers, and supervisors use “the A3” as a means by which they oversee and guide subordinates while simultaneously helping them develop their lean thinking and practice — particularly lean leadership and problem-solving — capabilities. With A3 management, leaders challenge their direct reports to solve a problem. Then, with the A3 report guiding the dialogue and analysis, leaders coach them through the problem-solving process. Importantly, leaders coach by asking questions versus providing answers, ensuring responsibility remains with the subordinate to solve the problem by pursuing facts and building consensus. Through this interaction, subordinates address the issue, allowing them to make progress toward the objective and, in so doing, learn the lean approach to leadership and management and gain problem-solving capability.

- A3 thinking (or analysis): Most A3 coaches and advanced lean practitioners refer to “the A3” as a thinking process. In this case, the term refers to a systematic approach to resolving problems or improving work processes. Someone can follow this systematic approach, regardless of whether they are guided by or record their findings on an A3 document.

- An alignment tool: Advanced lean organizations that have incorporated lean thinking and practices throughout their operations use “A3s” as part of their strategy deployment and execution efforts. In this case, the A3 process ensures a standard approach to managing and coaching people, all directed toward solving problems that help achieve corporate objectives.

Additional Resources

How Do I Start My A3?

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start the A3 by recognzing it as a thinking process.

Don’t Present Your A3: Share Your A3

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start by recognizing it as a thinking process.

Related Books

Related Online Courses

Intro to Problem Solving

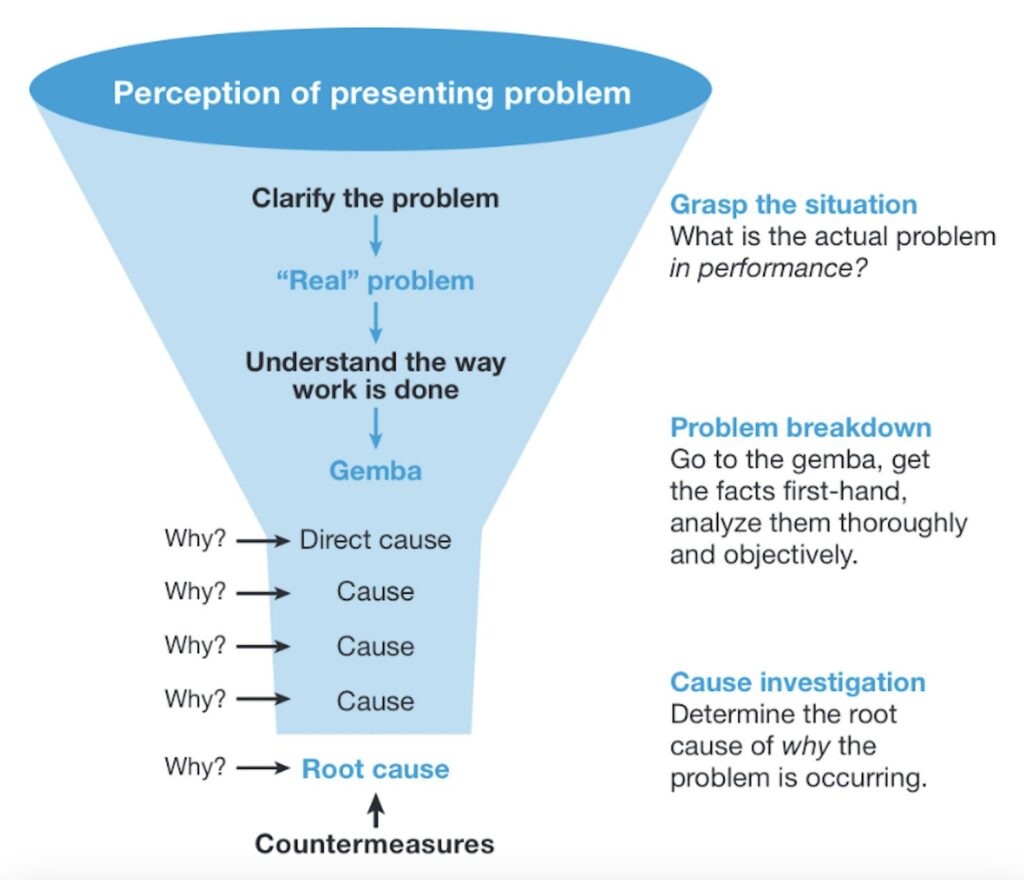

Problem-solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all of your senses to understand what is truly happening.

See: Value Stream Mapping

Privacy Overview

- Consultancy

- Online Courses

- Lean , Lean Culture , Lean Training , Lean Wiki , Tools

A Deep Dive into the A3 Problem-Solving Approach

- 11 mins to read

- June 20, 2023

- By Reagan Pannell

In today’s fast-paced and fiercely competitive business world, organisations must find ways to continuously adapt, evolve, and excel. Amidst the myriad methods and techniques for achieving improvements and driving continuous improvement , few have proven as profound and transformative as Toyota’s A3 problem-solving approach.

A significant driving force behind the company’s rise to global prominence, the A3 process fosters a culture where problems are embraced as opportunities for growth and learning. In this article, we’ll explore the origins and underlying principles of the A3 approach and uncover the secrets to its success in unlocking the power of improvements.

Understanding the A3 Approach

The A3 methodology is an integral part of the Toyota Production System (TPS), a set of principles and practices that have shaped the company’s approach to manufacturing, management, and continuous improvement over the years. Named after the A3 sheet of paper that was historically used to capture the plan, analysis, and follow-up on a single sheet of paper, typically an A3-sized sheet, the A3 process represents a simple, yet powerful, tool for addressing complex challenges and discovering lasting solutions.

At its core, the A3 approach is rooted in three key elements:

Thorough problem analysis : The foundation of the A3 process lies in digging deep to diagnose the true nature and root cause of an issue, rather than jumping to hastily devised fixes that merely address symptoms.

Structured documentation: The A3 report serves as both a communication tool and an iterative planning device, with each section building on the previous ones to guide problem solvers through a comprehensive analysis, solution development, and execution process. It’s the foundation of good continuous improvement.

Cyclical learning and improvement: Leadership and employees alike are encouraged to commit to hypothesis-driven inquiry, observation, experimentation, and reflection, leading to a culture that actively seeks and leverages opportunities for growth by solving problems.

How to Implement the A3 Process in Your Organisation

The Lean Thinking A3 approach can be distilled into seven essential steps:

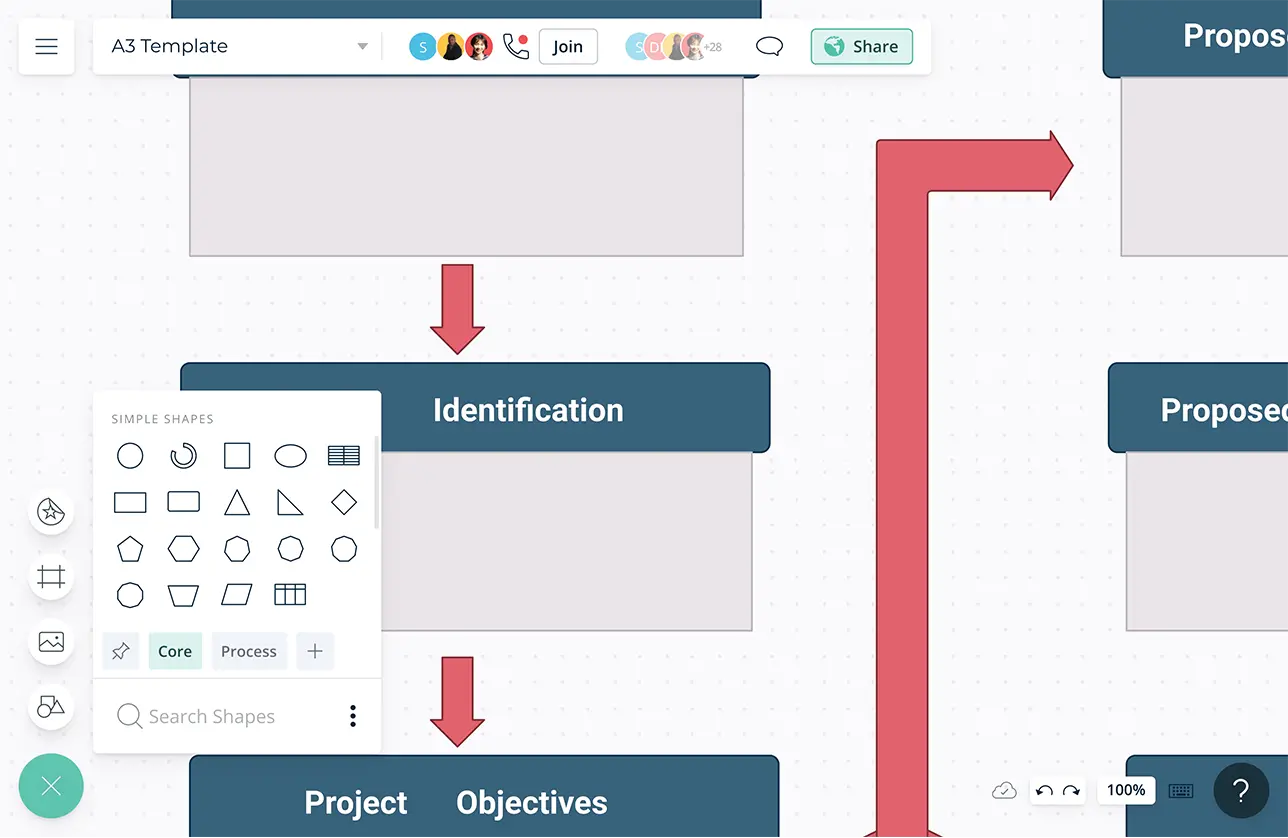

1. Identify the problem:

Clearly articulate and define the issue at hand, avoiding the temptation to jump to solutions or assume important facts to be self-evident..

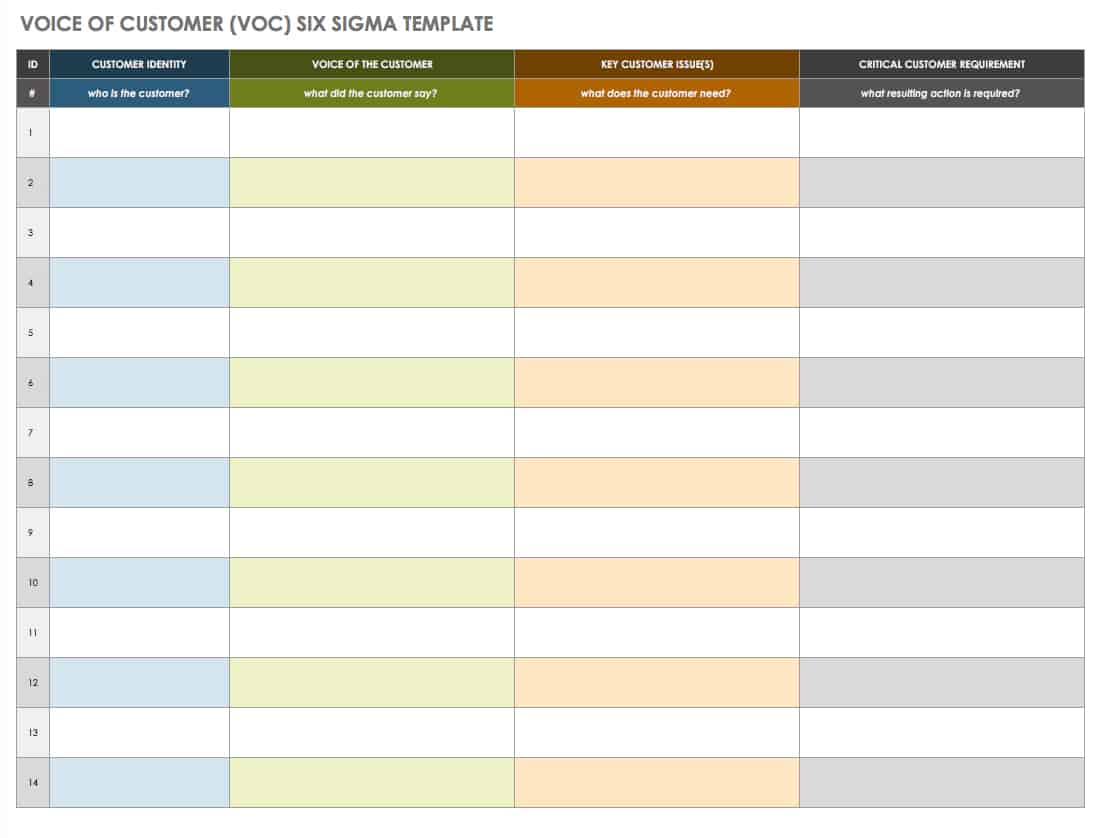

When identifying the problem, it is important to ensure that all relevant stakeholders in the organisation are consulted. This helps to ensure that the issue is accurately described and understood from multiple perspectives. A thorough problem analysis should also include conducting research into possible causes or root issues, and clearly documenting any observed symptoms of the problem. Additionally, it is essential to identify any major risks associated with not finding a solution and recognise any constraints (both external and internal) that may exist which could limit potential solutions. Lastly, it is important to consider any potential opportunities which may arise from addressing the issue that may have been overlooked at first glance. This is the problem statement part which is a critical component that identifies the difference between the current condition and the target condition.

At this stage, we are not looking at how to solve problems being faced or at the potential solution to solving problems. It’s about developing a good understanding of how the actual results differ from the expected results and providing an in-depth systematic approach to process improvement and developing problem-solving skills.

2. Establish the context and background:

Provide a high-level overview of the problem, describing the stakeholders involved, relevant data, and the broader organisational context in which the challenge has arisen..

It is important to ensure that all stakeholders are properly considered when identifying any potential solutions as their perspectives can play a vital role in determining an effective solution. All related data should be thoroughly analysed to understand the full scope of potential solutions. This includes resources, costs, timelines, and any legal or regulatory issues that may need to be considered. Additionally, it is important to consider how well-proposed solutions fit within existing organisational policies and procedures as this could impact implementation success. Finally, understanding how proposed solutions would interact with other initiatives or processes currently taking place in the organisation can help inform decisions about whether or not they are viable options. It may include conducting some value stream mapping to dig deeper into the current state.

It is important to fully explore any underlying factors that may be contributing to the issue at hand and ensure in-depth problem analysis. This includes looking deeper into existing systems, structures, and processes related to the problem in order to identify potential areas of improvement or optimisation. Additionally, it is essential to consider any relevant industry trends or external influences that could impact how the problem manifests within the organisation.

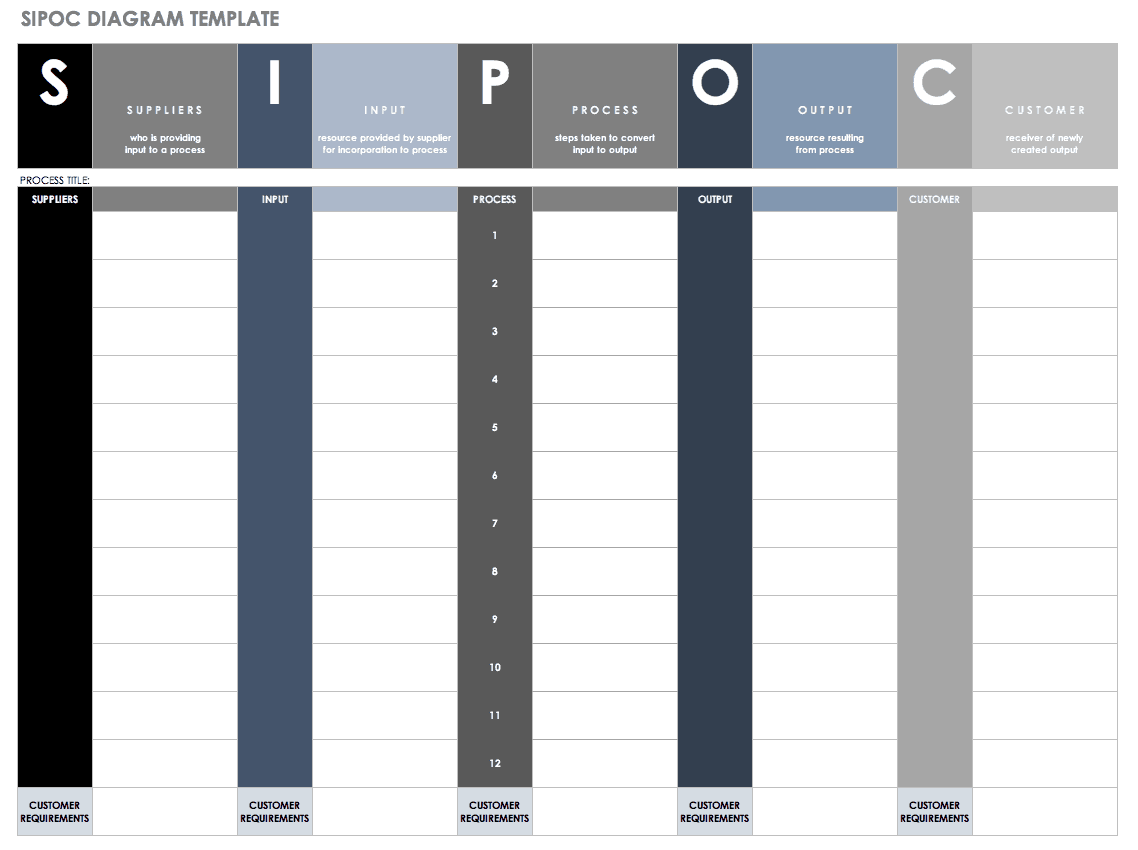

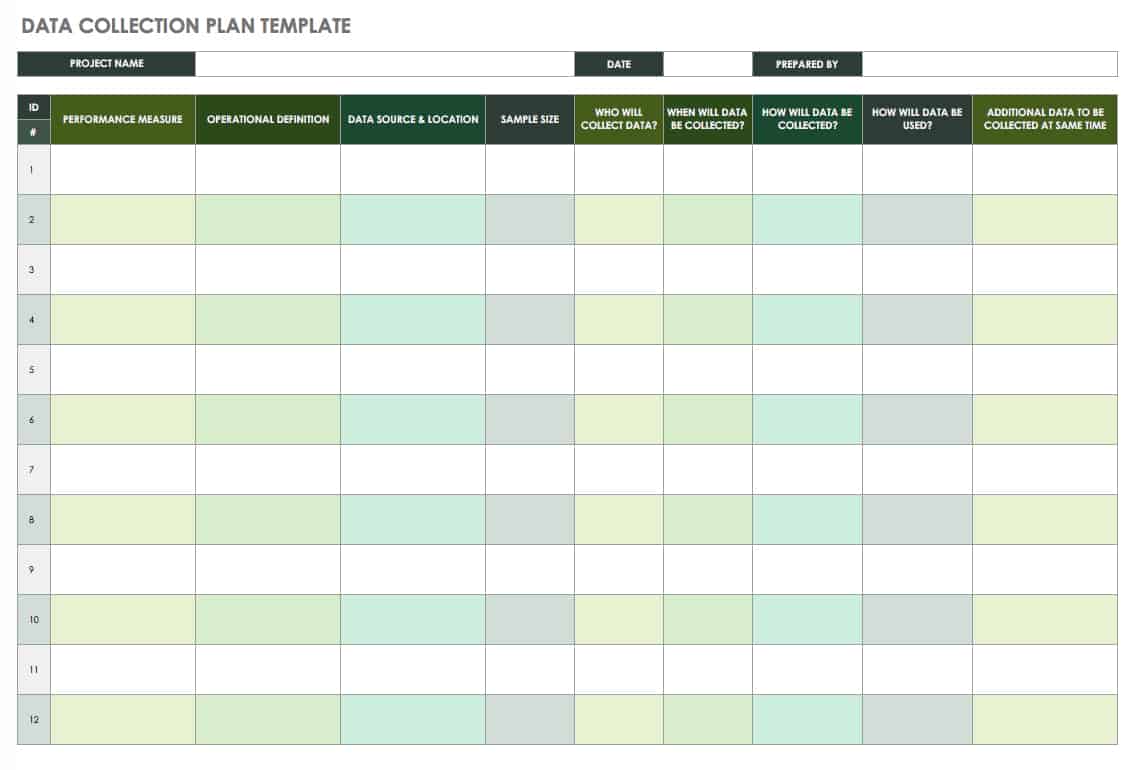

When analysing a problem, collecting data from various sources is important to get a more comprehensive understanding of how a particular issue can be addressed. This includes mapping the current process using the VSM, SIPOC , Process Mapping or Flowcharting techniques. Additionally, interviews and surveys can be conducted with stakeholders to gain insights into how they perceive the issue and their perspectives on potential solutions. Lastly, it is important to observe any real-world activities related to the problem to uncover key areas where time, effort, resources, money etc is being wasted. This is the time improvement that may not have been identified otherwise.

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, fundamentals of lean.

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LEAN SIX SIGMA GREEN BELT

Get 3-days free access to our green belt course, accelerate your career, 3. set a goal:, now that you have identified the problem and outlined the relevant context, it is time to set a project goal or outcome..

This involves clearly articulating the desired state of affairs and any key deliverables of the proposed solution. Whether it is reducing operational costs, increasing efficiency, improving customer experience, or something else entirely – defining specific objectives with measurable metrics can help ensure that project teams stay focused and remain aligned on their ultimate destination.

At this stage, it is also important to consider how long it will take to reach the desired outcome. Establishing an implementation timeline will help safeguard progress and provide a framework for tracking results along the way. Setting milestones for achieving particular goals at certain points in time can be especially helpful in keeping teams accountable throughout the process. Additionally, having a plan for evaluating success after reaching the end target will allow stakeholders to gain further insights into how effective their approach has been in addressing underlying problems, as well as how well-proposed solutions have fared once implemented.

4. Investigate root causes:

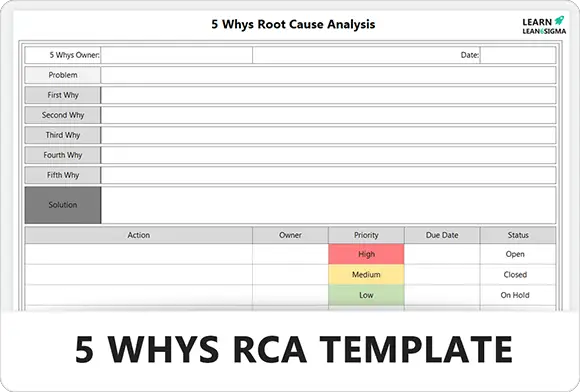

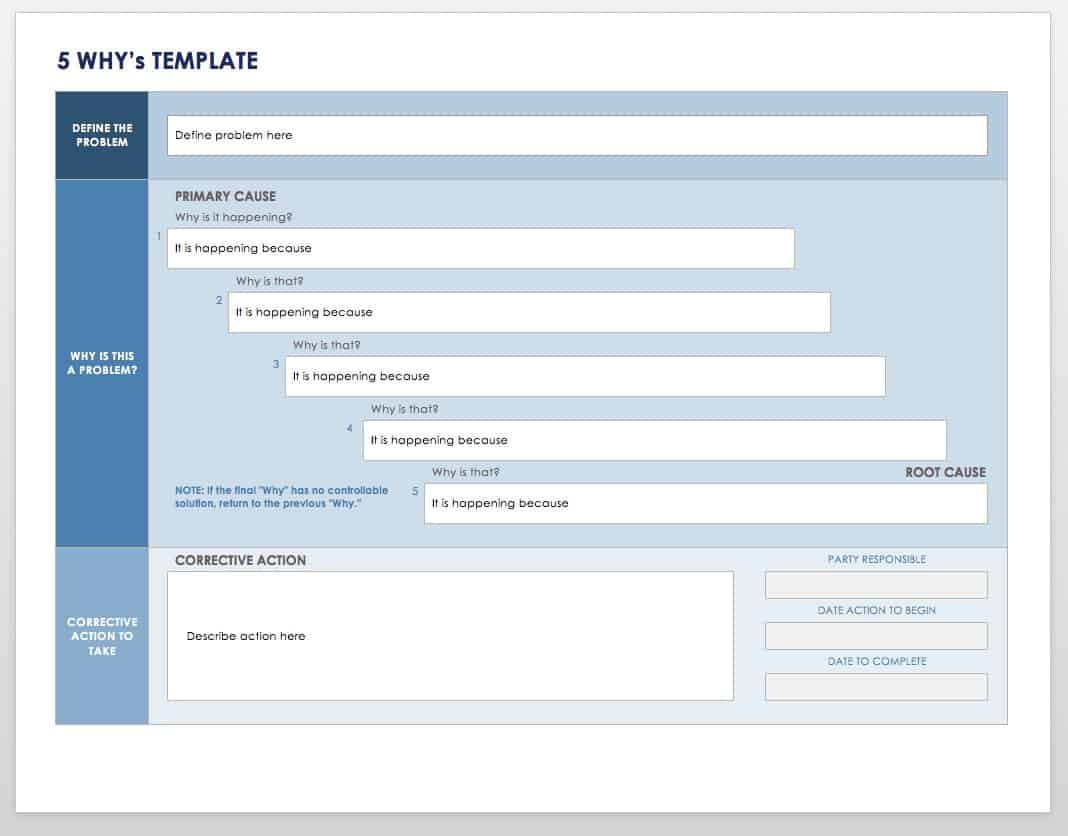

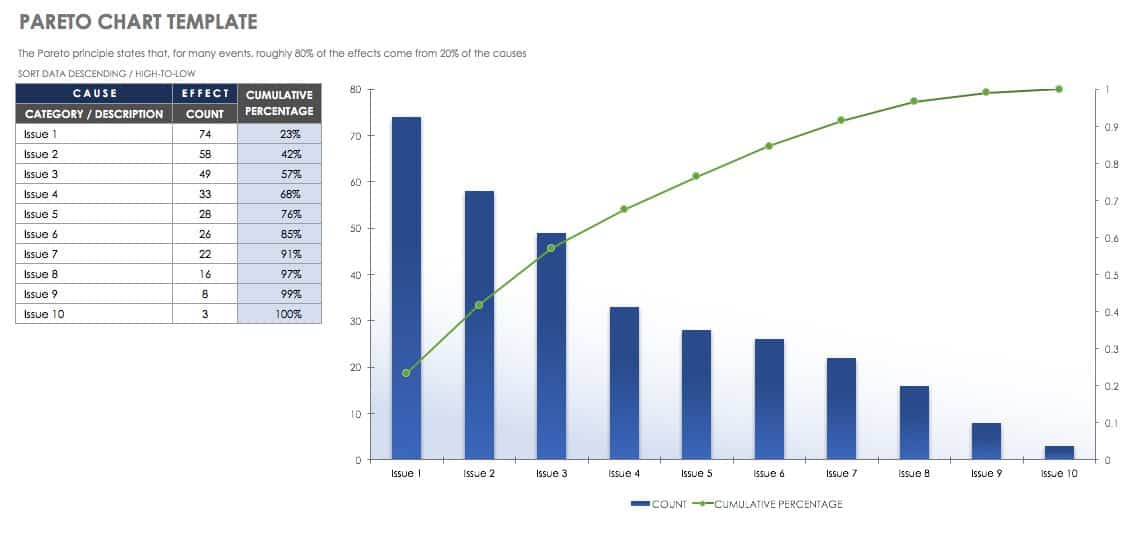

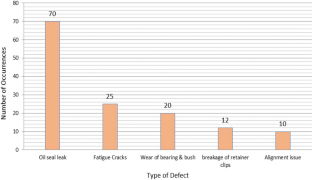

Use a variety of techniques (e.g., the 5 whys, fishbone diagrams, pareto charts) to probe the problem’s underlying causes and avoid settling on proximate reasons..

The process of identifying root causes is essential when using data-driven tools. We always want to find the simplest root cause approach.

One of the most widely used methods for root cause analysis is the ‘5 Whys’ technique. This method involves asking a series of ‘why’ questions to determine the underlying cause of a particular symptom or issue. The goal is to keep asking “Why?” until you reach an answer that can provide insight into how to address the problem and prevent it from occurring in the future.

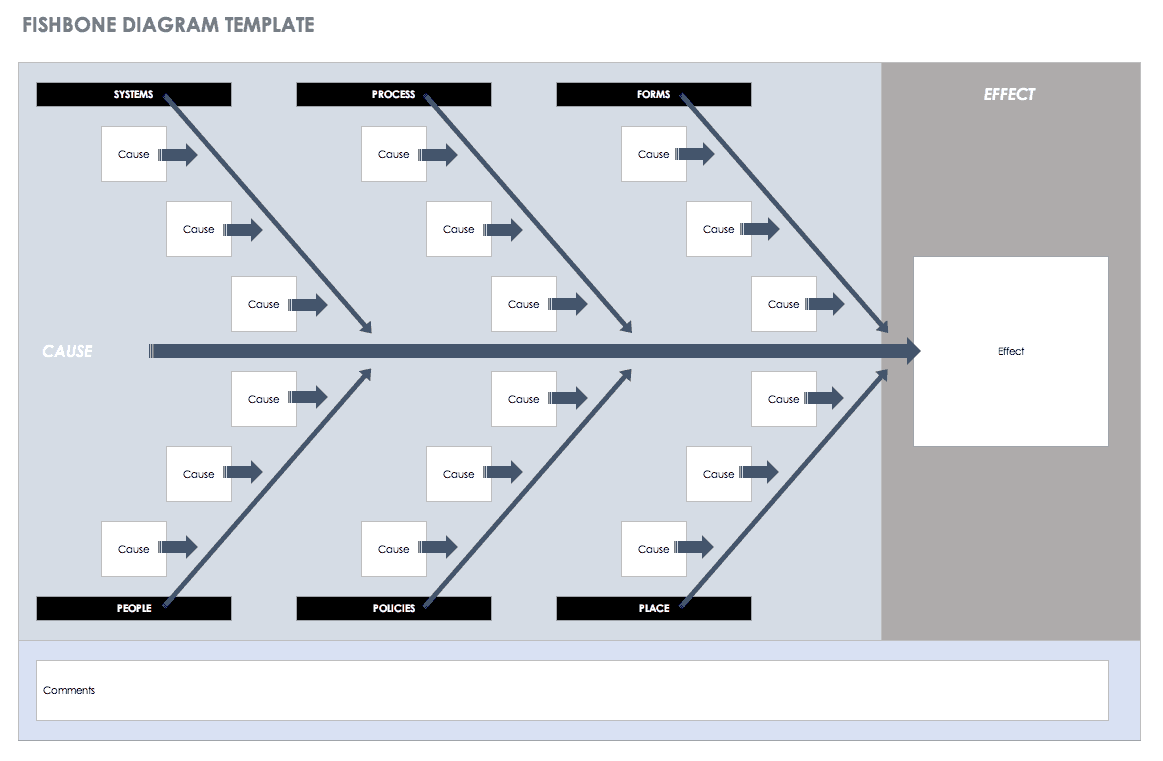

Another commonly used tool for root cause analysis is the fishbone diagram (also known as Ishikawa diagrams). This approach involves visualising all potential causes which could be causing a symptom or issue in a logical format, allowing users to identify patterns and uncover links between root causes and their respective effects. This technique can be helpful in identifying and focusing on key areas for improvement, as well as helping to identify interdependencies between components within an organisation’s systems.

Finally, Pareto Charts are useful for analysing data collected from surveys, interviews, observations, etc., concerning the severity or frequency of occurrence. This type of chart helps users quickly identify which factors are contributing most significantly towards an issue, allowing them to focus resources towards addressing those areas first and foremost. Additionally, Pareto charts can also be used to prioritise different solutions based on their estimated effectiveness in addressing an issue.

In conclusion, understanding the root cause of an issue through rigorous techniques such as 5 Whys, fishbone diagrams, and Pareto charts provides invaluable insight into how best to address it effectively while preventing it from reoccurring in the future. By leveraging these tools along with other data-led approaches such as process mapping and flowcharting, organisations can ensure that any proposed solutions are well-informed by both qualitative and quantitative data sources as well as ensure they are building consensus across the entire organisation.

5. Countermeasures:

Identify the right countermeasures (corrective actions) to implement that will directly impact the root causes identified..

Brainstorming is a useful tool for identifying potential improvements. It involves coming up with ideas and solutions in an open and collaborative manner, without judgement or criticism. By allowing team members to share their thoughts freely, brainstorming can help uncover innovative solutions that may have otherwise gone unnoticed. Additionally, looking at how waste reduction, flow and pull can be used to improve processes can also provide valuable insights into where improvement opportunities lie.

Brainstorm potential solutions that directly target the root causes and create detailed action plans for implementation, complete with assigned roles, responsibilities, and timelines.

Once the countermeasures are identified, it is important to design an implementation plan and assign roles & responsibilities. This will help ensure that all stakeholders understand their part in the implementation and can work together to achieve the desired outcome. Additionally, it is important to track progress along the way – setting measurable milestones that can be tracked against goals established during the initial problem-solving phase will help keep teams accountable and allow for course corrections if needed.

By utilising A3 Problem Solving Tools such as a template, organisations can easily document and share their analyses with relevant stakeholders throughout each stage of the project. Having detailed record-keeping like this also helps teams stay on target over time while providing insights into how proposed solutions may need to be re-evaluated down the line. This implementation plan provides the entire organisation with a clear project status on a one-page report.

6. Evaluate the results:

Measure the impact of your countermeasures against the problem, using well-defined success criteria, key performance indicators, or other relevant metrics..

Once the countermeasures have been implemented, it is essential to measure and evaluate their success. This can be done by tracking performance against the initial objectives established during the goal phase, as well as establishing key performance indicators to gauge how well the proposed solutions have fared.

Additionally, stakeholders should also consider conducting a post-implementation evaluation in order to assess how successful their approach has been in addressing underlying issues and determining what lessons can be learned from the experience. This will enable teams to identify strengths and weaknesses within their existing processes and make any necessary adjustments going forward. By understanding the outcomes of their improvements, organisations are able to gain valuable insights into how well they’ve succeeded in achieving their goals and ensure continued success moving forward.

Once the countermeasures have been implemented and their success measured, it is important to compare the results against the initial objective. This can be done in a variety of ways, including graphical analysis such as charts, process maps or flow diagrams. Graphical analysis helps to visualise the differences between results achieved before and after the implementation of new measures in a meaningful way. It also provides an increased level of clarity when assessing whether the desired outcomes have been achieved or not.

Process maps can be useful in understanding how changes made during the improvement phase have impacted processes within an organisation. By mapping out existing processes and then comparing them against those following implementation of countermeasures, teams can easily pinpoint where improvements were made and analyse how they led to improved performance overall.

Charts, on the other hand, enable users to quickly identify trends that may have emerged from data collected during the project. For example, if performance metrics are tracked before and after countermeasures are implemented, users can use charts and graphs to more clearly observe any patterns that may indicate an improvement or regression in performance over time – providing further insights into which areas need further attention or adjustment moving forward.

Finally, dashboard views provide an effective means of displaying results at a glance while highlighting any anomalies that might warrant further investigation. Dashboards allow stakeholders to gain access to important information quickly and easily while also helping them keep track of progress towards goals set out during initial problem-solving phases. Additionally, because dashboards support data visualisation capabilities they offer a highly interactive user experience which can help teams understand underlying trends with greater clarity and precision.

7. Standardise and share:

If a countermeasure proves successful, integrate it into the organisation’s standard operating procedures and share it with other teams as a best practice..

Once the countermeasures have been successfully implemented and measured against the initial objectives, these changes need to be integrated into the organisation’s standard operating procedures (SOPs) and shared with other teams as best practices. This will ensure that any improvements made during the problem-solving phase are consistently applied across all teams within the organisation.

In order to ensure that these improvements become part of the organisation’s long-term strategy, process maps should be updated to reflect the new improved way of working. Process maps provide a visual representation of how workflows are structured within an organisation, and by updating them in line with newly-implemented countermeasures, organisations can ensure that their processes continue to remain up-to-date and efficient moving forward. It may also be necessary to build a follow-up plan if not all tasks are fully completed as well as develop a Lean-focused PDCA cycle to ensure long-term effective collaboration on the solutions that were implemented.

Process documentation should also be updated in order to keep track of changes made during problem-solving. By documenting not just the solutions that were proposed but also why they were proposed, teams can gain valuable insights into their decision-making process which they can leverage for similar future problems.

Furthermore, it is important to update key performance indicators (KPIs) to accurately reflect any progress made during problem-solving. By tracking performance against objectives established before and after countermeasures were implemented, organisations will be able to identify any areas that may still need improvement or require further adjustment going forward. Additionally, tracking KPIs over time will help teams understand whether or not their current strategies are leading them towards meeting their goals in a timely manner or if additional measures may need to be taken in order to achieve desired results more quickly.

Finally, organisations should share successful solutions with other teams in order to promote collaboration and knowledge sharing amongst stakeholders throughout different parts of the business. This will allow for ideas generated through one team’s problem-solving efforts to benefit multiple departments – helping foster creativity and innovation while ensuring that everyone is on board with necessary changes being made throughout the organisation. The last step is key to Toyota’s PDCA management system designed for the entire organisation.

By breaking down the problem-solving process into these seven discrete stages, the A3 method offers practitioners a comprehensive, end-to-end framework for tackling complex challenges and driving improvements in any organisation.

- Lean Consultancy

- Corporate Training

Training the team on A3

To get A3 started, everyone in the entire organisation needs to learn how to use this single-sheet or single-page document. This means training people across all parts of the company so that everyone knows how to use the A3 Problem Solving Tool and A3 template. Training will help make sure that everyone follows a structured approach when using an A3 problem solving method, which is derived from Lean management and Six Sigma methodologies.

Getting the organisation fully onboard with A3 Problem Solving is not an easy task and will require a dedicated effort to ensure its successful implementation. To this end, it is important to start with specific areas of the business – whether it be operations, finance or marketing – by setting up targeted training sessions for both operational teams and senior managers. This will help everyone understand how and why A3 is used, as well as the potential benefits it can bring to their business.

Once everyone has mastered the basics of working with an A3 template, companies should look to regularly review and evaluate its effectiveness. This could include setting up quarterly reviews or running workshops where teams discuss successes and areas for improvement when using the A3 tool. Doing this will ensure that any issues are identified early on, allowing the team to quickly adjust accordingly.

At Leanscape, we understand that transitioning to A3 Problem Solving can be a daunting task. With our team of specialists, we can provide your teams with the necessary training and coaching to ensure that they are able to adapt quickly and efficiently. Our comprehensive approach to A3 will equip your team with the knowledge and skills needed to successfully use this powerful tool for improving performance in all areas of your business.

We are committed to helping you develop a culture of continuous improvement within your organisation by teaching best practices and providing guidance through every step of the problem-solving process. Through our specialised training programs, we will help your teams learn how to use the A3 template more effectively, as well as how to interpret data visualisations quickly and accurately – enabling them to take action swiftly when required. Our experienced coaches will also share insights from industry experts on how best to integrate countermeasures into standard operating procedures (SOPs) and process maps, keeping up-to-date with industry trends in order to stay ahead of the competition.

By leveraging Leanscape’s expertise in A3 Problem Solving, you can rest assured knowing that your team is in good hands. Our team is dedicated to providing you with the support needed for successful implementation so that you can achieve sustained performance improvements over time.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Lean Six Sigma Yellow Belt Certification Course

The implementation of A3 Problem Solving provides a comprehensive framework for organisations looking to successfully address complex problems in an efficient and cost-effective manner. By breaking down the problem-solving process into seven distinct stages, users can structure their approach and track the progress of their countermeasures over time.

In order to ensure successful implementation, organisations should dedicate time towards training their teams on how to use the A3 Problem Solving Tool and A3 template. This will give everyone a solid foundation for carrying out future problem-solving activities more effectively, as well as provide insights into the effectiveness of certain countermeasures over time.

Through Leanscape’s specialised training programs, you can ensure that your team is fully equipped with the necessary skills to successfully adopt and incorporate A3 problem-solving into all areas of your business. Our experienced coaches are committed to helping you develop a culture of continuous improvement within your organisation – providing guidance through every step of the process.

Final Thoughts

The A3 approach is an invaluable tool for unlocking the power of improvements within any organisation. By leveraging its structured framework and cyclical learning approach, businesses can remain agile and responsive to ever-changing conditions, allowing them to navigate change more successfully and emerge stronger than ever before. Ultimately, this makes Toyota’s A3 problem-solving process one of the most effective ways to ensure long-term success in today’s fast-paced and competitive market.

Stay current with our latest insights

- Lean Six Sigma Yellow Belt Course

Our Training Courses

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, leanscape announces leadership coaching services, unlock business innovation with the lean business model canvas, 2024 recommended reads for transformative thinking, 10 best books on agile, scrum and design thinking, the ultimate guide to lean and manufacturing: boosting efficiency and productivity, 10 best management books for leaders and change makers, view all articles, green belt course, other articles, what is kanban explained in 10 minutes, using the probability plot | probability distribution tool, problem solving is a must have in the workplace, here is why, empowering leaders: the imperative for problem-solving training, an introduction to correlation and regression analysis, histogram: a comprehensive guide, principle 7: visual management in lean | the 3 second rule, how business and management are connected, poka yoke: the lean concept of mistake proofing, total preventive maintenance: the importance of tpm – leanscape, an operational excellence training program delivers $4m in costs savings, what are objectives and key results (okrs) ensuring execution.

- | lean , lean thinking , problem solving , toolkit , tools

Related Articles

The vital role of successfully adopting lean in driving operational improvement, from chaos to clarity: how gantt charts can streamline your project management, how lean six sigma yellow belt will accelerate your career, kaizen vs kaikaku – understanding the difference, which six sigma certification is most recognized in the uk, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

Six Sigma Mania

Download many Lean Six Sigma Templates

How to use A3 report – example and template for free

A3 report is one page report about project progress, its background, and challenges. It is easily explanation tool for broader audience, and stakeholders interested in the project.

this article contains:

What is A3 problem solving report?

A3 report out as a option, steps to create a3 report, a3 report example – restaurant improvement, a3 report at project start, a3 report as project progress, a3 report at project end.

- A3 report template download

Hot news, folks. In order to help you as much as I can in your improvement efforts, I have launched non-binding consultation program. I would like to help you with:

- Lean culture implementation in your organization

- Six Sigma projects consultations

- Lean Six Sigma trainings and certifications support

- Project management theory turn into practical usage

- Your career planning

First 30 minutes of consultation for free, every additional 1 hour 10 USD.

On a literal level, A3 refers to a paper size 29.7 x 42.0 in cm 11×17 in inches. In the lean six sigma world, we use this report out tool to show teams thinking, when addressing project goal. Use A3 during whole project life cycle. Create A3 right after project charter creation.

Six sigma tools to use in your (not just) first project – read here

Well, I suggest to agree with stakeholders, the way they want to see project report out. There are different ways possible. And A3 is one of possibilities.

So, no need to use A3 in every project. But be consistent, once using it.

A3 creation, preparation and updating is much faster, than creating presentation for example. It is simple to use and read. It is great tool, when presenting more projects updates in one meeting. A3 helps team focusing on the project goal and its deliverables, and makes it much simpler to review progress for those interested in the project.

5 simple Green belt project ideas – read here

A3 form template, is available for download in the end of this article. For free. Use it, share it.

These are areas should be filled at project beginning, as already mentioned.

- Project name,

- Current state pains

- Project goal, and the

- Section with team information

It takes some time with working on projects following DMAIC. But it worth it. So, do not jump into the solutions however attractive and tempting it would be. Try to understand current problem, identify your ideal state, and create a plan to reach it.

Here is a link to download project charter template for your usage, with the brief description of each section. You are free to share and distribute this list.

I do videos, blog posts, and all templates for free, in my free time. I will appreciate if you can donate me a cup of cofee, for more energy in my creation. (1 dollar counts, too 😉 Click on this link: I would like to support Erik in his effort

A3 sections to be updated this way..

- Create 4 sections prior project start, as mentioned.

- Develop high level activities and their schedule in project beginning together with team. It can be DMAIC phases at beginning. You can add more details as progressing with project.

- Update the rest of A3 areas with project progress. Do the update together with your team.

- Review A3 during one on one project progress review with sponsor, prior showing to stakeholders.

- Update stakeholders regularly. Minimally after finishing each project phase.

What are Six Sigma project types? (+templates) – read here

Let me share an A3 report example with you. A3 refers to my earlier video – improving fast food restaurant, called “Eating mania”.

OK, you can argue, that there is no real stakeholder in this project, to whom to report out. It is true statement. I will show correlations between project, and reporting out progress by A3.

Restaurant owner has a problem with very slow business growth. And he would like to develop process, that would bring 15% more customers in 3 months. This is perfect project goal.

Download DMAIC tools list, I suggest allways to follow.

22 green belt certification companies prices review – read here

And this is how A3 would look like when project starts:

Team have developed high level project plan right after project kick off. There are leaders of each step, time frame where each step should be addressed. It needs teams discussions to define those steps, when there is no experienced leader.

How to select your first green belt project? – read here

As team is progressing, accomplished tasks are updated with current status. Additional information, as Analysis, and project challenges is provided to the report. Use pictures, graphs or other visualization to show used tools in the analyze section.

Follow ups and challenges are here to share with stakeholders and sponsor, what difficulties team is facing. You might ask for helping hand in the case team is stuck up.

You can update any A3 section accordingly, as project goes on. It must reflect reality.

Construction DMAIC improvement example – read here

And this is A3 after finishing whole project. Note, there are project results showed in follow up, and analyze section. It is important to share positive things, as well as those, which did not run very well, and need some more attention, or different approach.

And there you are. Filled A3 report after project finalization.

A3 report template

What you will get, by downloading this file:

- A3 form Excel template

- Restaurant example – filled A3 report (above used pictures)

To download entire A3 report template –click on the link below

Do not forget to visit and subscribe my YouTube channel . I am uploading Six Sigma, Lean and Project oriented videos regurarly. So, stay tuned.

Yours sincerely Erik.

Related Post

Mastering A3 Problem Solving: The Essential Guide to Improving Processes and Solving Complex Problems

What is A3 Problem Solving?

A3 problem solving definition.

A3 problem solving is a Lean Six Sigma project management tool that uses a structured problem-solving approach to improve process efficiency and product quality. A3 problem solving is based on the A3 process, a problem-solving methodology developed by Toyota in the 1960s. The process was named after the A3-size paper that was traditionally used to document the problem-solving process. In this blog post, we will discuss the origins of A3 problem solving, its key components, steps to run the A3 Problem Solving process, A3 report preparation, some examples on the A3 Problem Solving, and common mistakes to avoid.

Origins of A3 problem solving

A3 problem solving was developed by Toyota as a means to improve the quality of their products and streamline their manufacturing processes. The methodology was developed in the 1960s by Toyota’s Chief Engineer, Taiichi Ohno. Ohno used the A3 process to document and solve problems within the manufacturing process. Over time, the A3 process became a key component of Toyota’s lean manufacturing philosophy and was adopted by other companies looking to improve their processes and products.

When and in What Situation to Apply A3 Problem Solving?

A3 problem solving is a structured approach that can be used to solve complex problems and improve processes. It can be applied in a wide range of situations across various industries. Here are some specific scenarios where A3 problem solving can be particularly useful:

- When faced with a significant problem or challenge that requires a structured approach to identify the root cause and develop effective solutions.

- When there is a need to improve the quality of a product or service, reduce defects or errors, or address customer complaints.

- When there is a need to streamline a process, reduce waste, or improve efficiency to save costs or improve productivity.

- When starting a new project or product development initiative and there is a need to identify potential issues and develop a plan to mitigate them.

- When there is a need to identify opportunities for continuous improvement and make incremental improvements to an existing process.

- When there is a need to implement changes in a process or system that affect multiple departments or stakeholders and there is a need to ensure that the changes are properly planned and executed.

Overall, A3 problem solving can be used in a wide range of situations where there is a need for a structured approach to problem solving and improvement. By following the A3 process, organizations can identify and address root causes, develop effective solutions, and implement changes that lead to continuous improvement and better outcomes.

Key components of A3 problem solving

A3 problem solving is a structured approach that follows a set of steps to identify, analyze, and solve problems. The key components of A3 problem solving include identifying the problem, gathering data, analyzing the data, developing a solution, implementing the solution, and monitoring the results. A3 problem solving also involves using A3 thinking, which is a mindset that encourages continuous improvement and problem-solving through collaboration and teamwork.

8 Steps to run the A3 Problem Solving process

Running A3 problem solving involves following a structured problem-solving approach to identify and solve problems within an organization. Here is a step-by-step guide on how to run the A3 problem solving process:

Step 1: Clarify the Problem

The first step in the A3 problem-solving process is to clearly define the problem. It’s important to gather all the relevant information, including when the problem occurred, where it occurred, and who was involved. This will help to ensure that everyone involved in the process has a clear understanding of the problem and can work together to find a solution.

Step 2: Break Down the Problem

After clarifying the problem, it’s time to break it down into manageable parts. This step involves analyzing the problem and identifying the specific areas that need improvement. This may involve creating a process map or a flowchart to better understand the issue.

Step 3: Set a Target

The next step is to set a target for what the ideal outcome would be. This involves identifying what success looks like and what metrics will be used to measure progress. The target should be specific, measurable, achievable, relevant, and time-bound (SMART).

Step 4: Analyze the Root Cause

To develop effective countermeasures, it’s important to understand the root cause of the problem. This step involves analyzing the data collected in steps one and two to identify the underlying cause of the problem. This may involve using tools such as the 5 Whys, Ishikawa diagrams, or Pareto charts.

Step 5: Develop Countermeasures

Once the root cause has been identified, it’s time to develop countermeasures to address the problem. This step involves brainstorming potential solutions and selecting the best course of action. It’s important to involve all stakeholders in this step to ensure buy-in and support for the chosen solution.

Step 6: Implement the Countermeasures

With a solution in place, it’s time to implement the countermeasures. This may involve testing the solution on a small scale to ensure it’s effective before rolling it out more broadly. It’s important to document the implementation process to ensure that everyone involved is on the same page.

Step 7: Evaluate Results

After implementing the countermeasures, it’s important to evaluate the results. This step involves measuring progress against the target set in step three and determining whether the countermeasures have been effective. If the results are not satisfactory, it may be necessary to go back to step four and analyze the root cause again.

Step 8: Standardize

The final step is to standardize the solution to ensure that the problem does not occur again in the future. This may involve creating a new standard operating procedure or updating an existing one. It’s important to communicate the new process to all stakeholders to ensure that everyone is on the same page.

In conclusion, the A3 Problem Solving process is an effective tool for addressing problems in any organization. By following the 8 steps outlined in this post, organizations can develop effective solutions that address the root cause of the problem and ensure that it doesn’t occur again in the future.

A3 report generation

One of the key outputs of the A3 process is the A3 Problem Solving report. In this blog post, we will provide a step-by-step guide on how to generate an A3 Problem Solving report based on the 8 steps of the A3 process.

The first section of the A3 report should clearly state the problem that needs to be addressed. It should describe the current situation, including the impact of the problem on the organization and the stakeholders involved.

The second section of the report should break down the problem into manageable parts. This may involve creating a process map or a flowchart to better understand the issue. The goal is to identify the specific areas that need improvement.

The third section of the report should set a target for what the ideal outcome would be. This involves identifying what success looks like and what metrics will be used to measure progress. The target should be specific, measurable, achievable, relevant, and time-bound (SMART).

The fourth section of the report should analyze the root cause of the problem. This involves analyzing the data collected in steps one and two to identify the underlying cause of the problem. This may involve using tools such as the 5 Whys, Ishikawa diagrams, or Pareto charts.

The fifth section of the report should describe the countermeasures that have been developed to address the problem. This may involve brainstorming potential solutions and selecting the best course of action. It’s important to involve all stakeholders in this step to ensure buy-in and support for the chosen solution.

The sixth section of the report should describe how the countermeasures will be implemented. This may involve testing the solution on a small scale to ensure it’s effective before rolling it out more broadly. It’s important to document the implementation process to ensure that everyone involved is on the same page.

The seventh section of the report should evaluate the results of the countermeasures. This involves measuring progress against the target set in step three and determining whether the countermeasures have been effective. If the results are not satisfactory, it may be necessary to go back to step four and analyze the root cause again.

The final section of the report should describe how the solution will be standardized to ensure that the problem does not occur again in the future. This may involve creating a new standard operating procedure or updating an existing one. It’s important to communicate the new process to all stakeholders to ensure that everyone is on the same page.

In conclusion, generating an A3 Problem Solving report requires following the 8 steps of the A3 process. By providing a clear description of the problem, breaking it down into manageable parts, setting a target, analyzing the root cause, developing effective countermeasures, implementing those countermeasures, evaluating the results, and standardizing the solution, organizations can solve problems in a structured and effective way. By using the A3 report as a tool for communication, organizations can ensure that all stakeholders are on the same page and working towards a common goal.

Examples of successful A3 problem solving

A3 problem solving has proven to be effective across a diverse range of industries. In the following, you’ll find three instances of A3 Problem Solving reports that showcase its success.

Example 1: A3 Problem Solving reports for High Scrap Rate

| Problem: High Scrap Rates |

|---|

| Current scrap rates are at 15% |

| Scrap is impacting profitability and customer satisfaction |

| Identified multiple sources of scrap including defective raw materials, incorrect machine settings, and operator error |

| Conducted a process map to understand the flow of materials and identify areas for improvement |

| Set a target to reduce scrap rates by 50% within 3 months |

| Conducted a Pareto analysis to identify the most significant sources of scrap |

| Used the 5 Whys to determine that operator error was a key root cause |

| Implemented additional training for operators to reduce errors |

| Implemented a quality control process to ensure raw materials meet specifications |

| Conducted training for all operators and quality control personnel |

| Updated standard operating procedures to reflect the new processes |

| Monitored scrap rates over a 3-month period |

| Scrap rates decreased from 15% to 7% |

| Updated standard operating procedures to reflect the new processes |

Example 2: A3 Problem Solving reports for Late Deliveries

| Problem: Late Deliveries |

|---|

| Delivery times are often delayed, causing customer dissatisfaction |

| Late deliveries are impacting profitability and customer satisfaction |

| Identified multiple factors contributing to late deliveries including inefficient transportation routes, lack of communication with customers, and delays in the production process |

| Conducted a process map to understand the flow of materials and identify areas for improvement |

| Set a target to improve on-time delivery to 95% or higher within 6 months |

| Conducted a Fishbone analysis to identify the root cause of the late deliveries |

| Identified that inefficient transportation routes and lack of communication with customers were the primary causes of late deliveries |

| Developed a new transportation plan that optimizes routes and reduces delivery times |

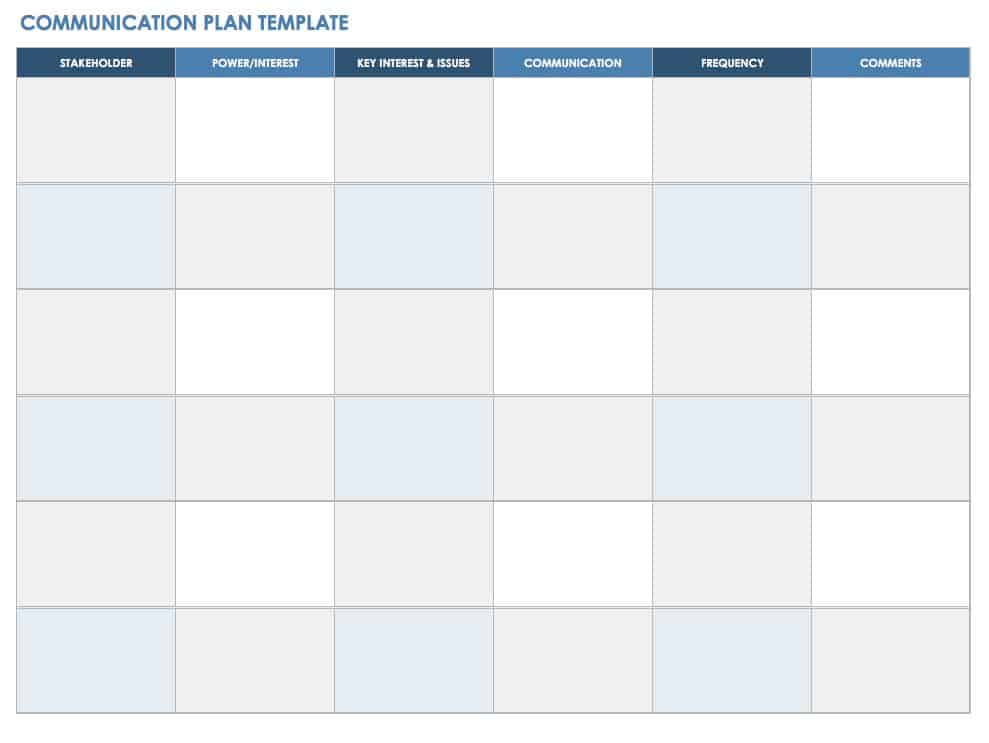

| Implemented a customer communication plan that provides regular updates on delivery status |

| Implemented the new transportation plan and customer communication plan |

| Conducted training for all employees on the new processes |

| Monitored on-time delivery rates over a 6-month period |

| On-time delivery rates increased from 80% to 95% |

| Updated standard operating procedures to reflect the new processes |

Example 3: A3 Problem Solving reports for Low Employee Morale

| Problem: Low Employee Morale |

|---|

| Employee satisfaction is low, leading to low productivity and high turnover rates |

| Conducted a survey to understand the factors contributing to low employee morale |

| Identified lack of recognition, poor communication, and limited opportunities for growth as key factors |

| Set a target to increase employee satisfaction by 25% within 6 months |

| Conducted a Fishbone analysis to identify the root causes of low employee morale |

| Identified that lack of recognition, poor communication, and limited opportunities for growth were the primary causes |

| Developed an employee recognition program that rewards employees for outstanding performance |

| Implemented regular team meetings to improve communication and collaboration |

| Developed a career development plan to provide employees with opportunities for growth and advancement |

| Launched the employee recognition program and conducted training for all employees and managers |

| Held regular team meetings and provided regular communication updates |

| Implemented the career development plan and conducted training for all employees and managers |

| Conducted a follow-up survey after 6 months to assess employee satisfaction levels |

| Employee satisfaction increased by 30% |

| Updated standard operating procedures to reflect the new processes |

Common mistakes to avoid when implementing A3 problem solving

There are several common mistakes that organizations make when implementing A3 problem solving:

- Lack of clarity: Not having a clear problem statement can lead to wasted time and resources. It’s important to spend time defining and clarifying the problem at the beginning of the A3 process.

- Skipping steps: The A3 process is designed to be followed in a specific order, and skipping steps can lead to incomplete or ineffective solutions. It’s important to resist the urge to jump ahead and stick to the process.

- Rushing the process: A3 problem solving requires time and effort to be effective. Rushing through the process or trying to cut corners can lead to subpar solutions that don’t fully address the problem.

- Focusing on symptoms instead of root causes: It’s easy to address symptoms of a problem without addressing the underlying root causes. It’s important to take the time to identify and address root causes to prevent the problem from recurring.

- Lack of cross-functional involvement: A3 problem solving involves multiple departments and stakeholders, and not involving all relevant parties can lead to incomplete or biased solutions. It’s important to involve all necessary parties from the beginning of the process.

- Overcomplicating the process: A3 problem solving is meant to be a simple and straightforward process, and overcomplicating it can lead to confusion and frustration. It’s important to keep the process as simple and clear as possible.

- Ignoring feedback and results: A3 problem solving requires ongoing evaluation and feedback to determine the effectiveness of the solutions. Ignoring feedback or failing to measure results can lead to missed opportunities for improvement.

- Lack of standardization: A3 problem solving should be standardized across an organization to ensure consistency and effectiveness. Failing to standardize the process can lead to confusion and inconsistency in results.

A3 problem solving is a powerful tool that can help organizations improve their processes and products. The methodology is based on a structured problem-solving approach that involves identifying the problem, gathering data, analyzing the data, developing a solution, implementing the solution, and monitoring the results. A3 problem solving offers several benefits to organizations, including improved problem-solving skills, increased productivity, reduced costs, improved quality, and enhanced customer satisfaction. By following the A3 process closely and avoiding common mistakes, organizations can successfully implement A3 problem solving and achieve significant improvements in their operations.

- Toyota Production System: An Integrated Approach to Just-In-Time by Yasuhiro Monden

- “Using A3 Thinking to Improve the Emergency Department Discharge Process” by J. T. Fingarson, D. K. M. Blackmore, and A. J. Auerbach

The Ultimate Guide to RACI Charts (RACI Matrix Examples): Boosting Accountability and Collaboration in Your Team

From Inputs to Outputs: How SIPOC Mapping Simplifies Process Understanding

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Reach out to us

Our proven process equips individuals with proven method and skills to create positive change and improve efficiency while reducing errors

© 2024 leansixsigmamadeeasy.com

A3 Problem Solving Tool

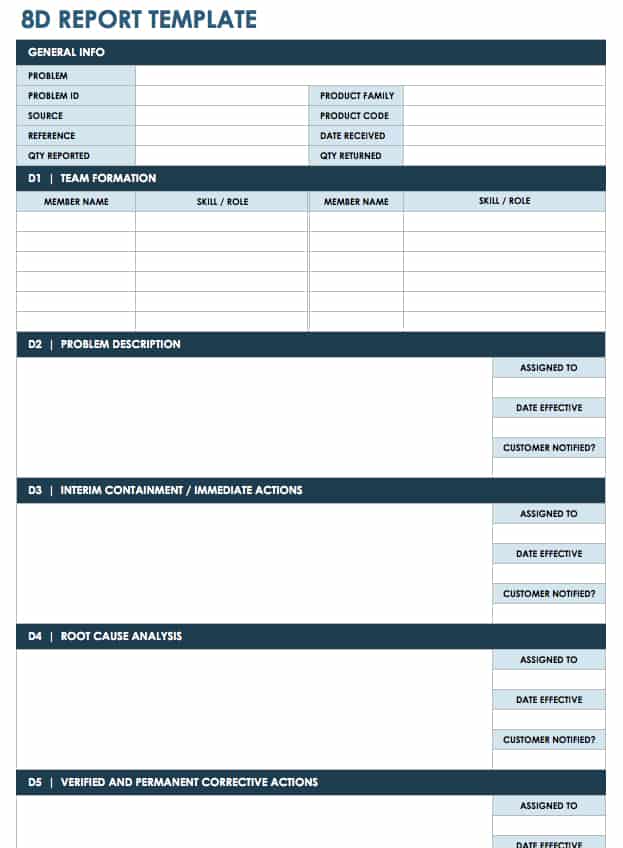

The A3 methodology is problem solving tool first introduced by Toyota and is more than a root cause indicator such as a Fishbone Diagram . Toyota's goal was to capture the problem, the analysis, corrective actions and tracking of action plans all onto one sheet of paper.

The A3 name comes from the size of the paper. It's an international term for paper measuring 297 mm wide by 420 mm in length. The closest paper size commonly used in the United States is 11"*17".

The A3 problem solving tool was widely used at Toyota to standardize and simply communication. In many cases it is used as that generally applies subjective analysis .

The A3 format is designed to have all the following on this one sheet of paper:

- Problem identification

- Clarification

A3 is a key component of Toyota problem solving process based on the PDCA cycle. It applies to all levels of the workforce. The Plan-Do-Check-Act cycle is fully encompassed in this tool from the scope to sustaining the gains and spreading them company wide.

It is a communication tool for workers to report problems and gain support to address issues and fix them. For that reason, the A3 is often created by hand and posted in highly visible area.

The A3 progress is typically reviewed (during audits or GEMBA walks) on a daily basis. It takes time to complete the tool, it isn't intended to be done in one sitting.

Like many of the Six Sigma and Lean tools, they won't be successful unless supported by the culture of continuous improvement and passion to embrace change, experiment, and have the genuine support from all levels within an organization.

A3 Structure

There are several variations of the flow within the sheet. Exactly how each sheet of paper may look, the tools used, depends on the problem. The general flow is show below however the most important thing is to capture the key relevant information, in sequential flow, on the paper...the exact location on the paper isn't as important.

Left Side of A3 - PLAN

Top Left Corner : Similar to a Project Charter. A background and statement of the current state along with a problem statement. A statement about the objective and desired final state.

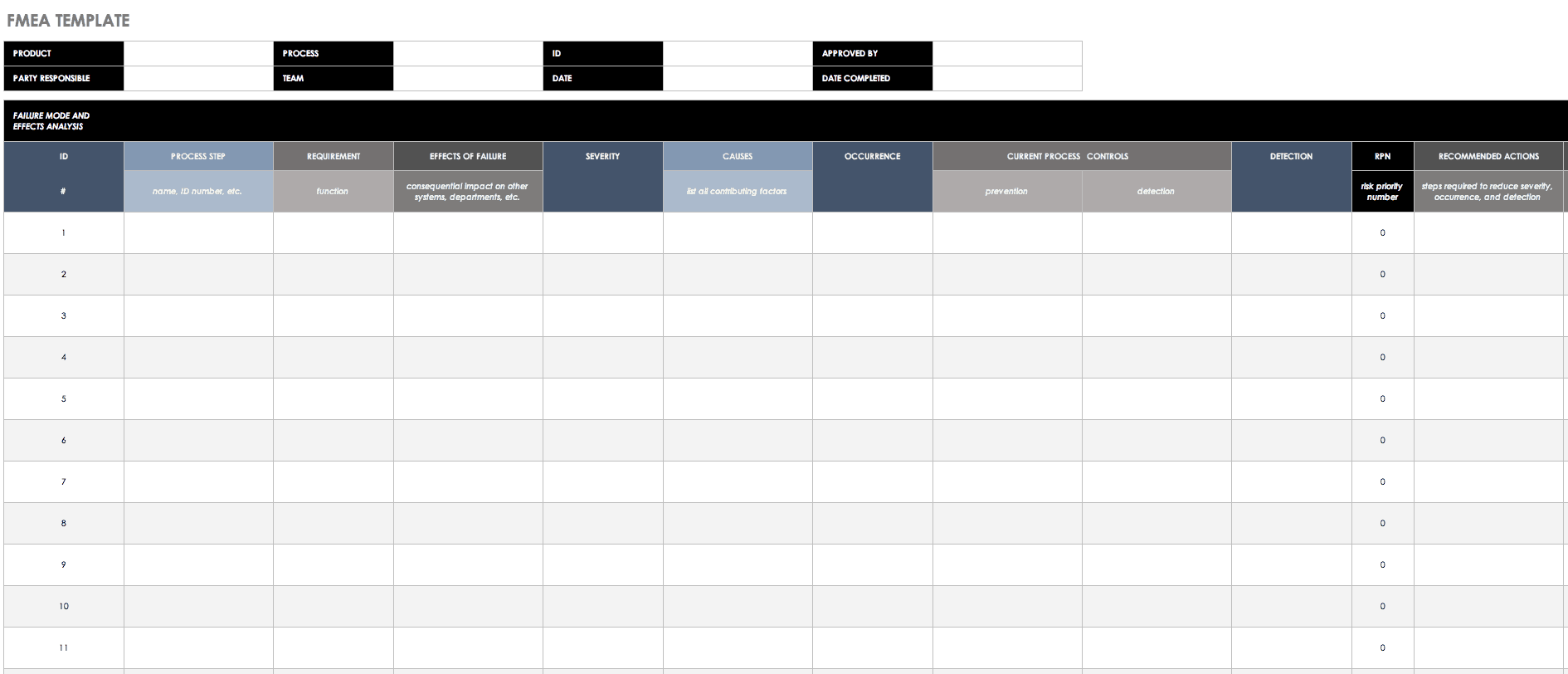

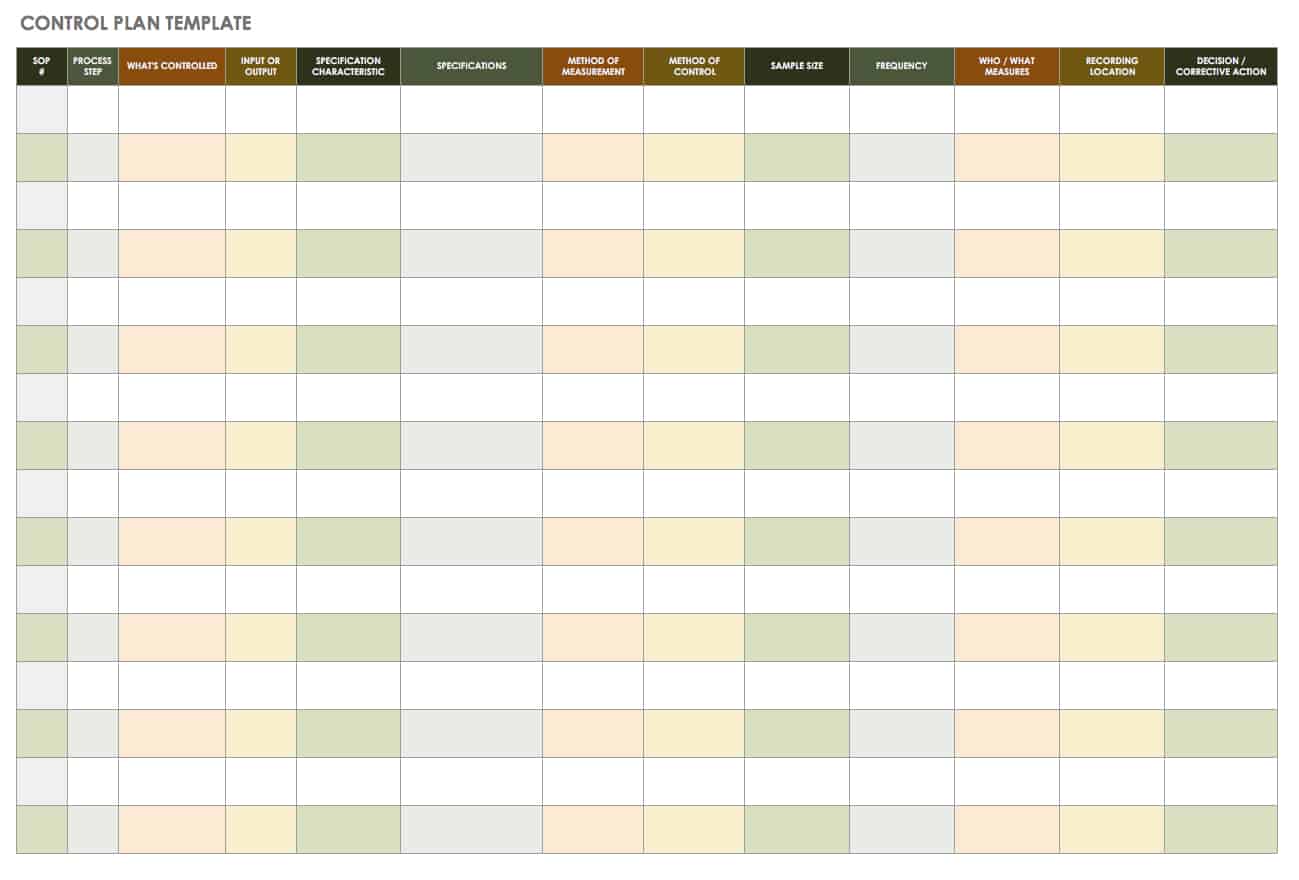

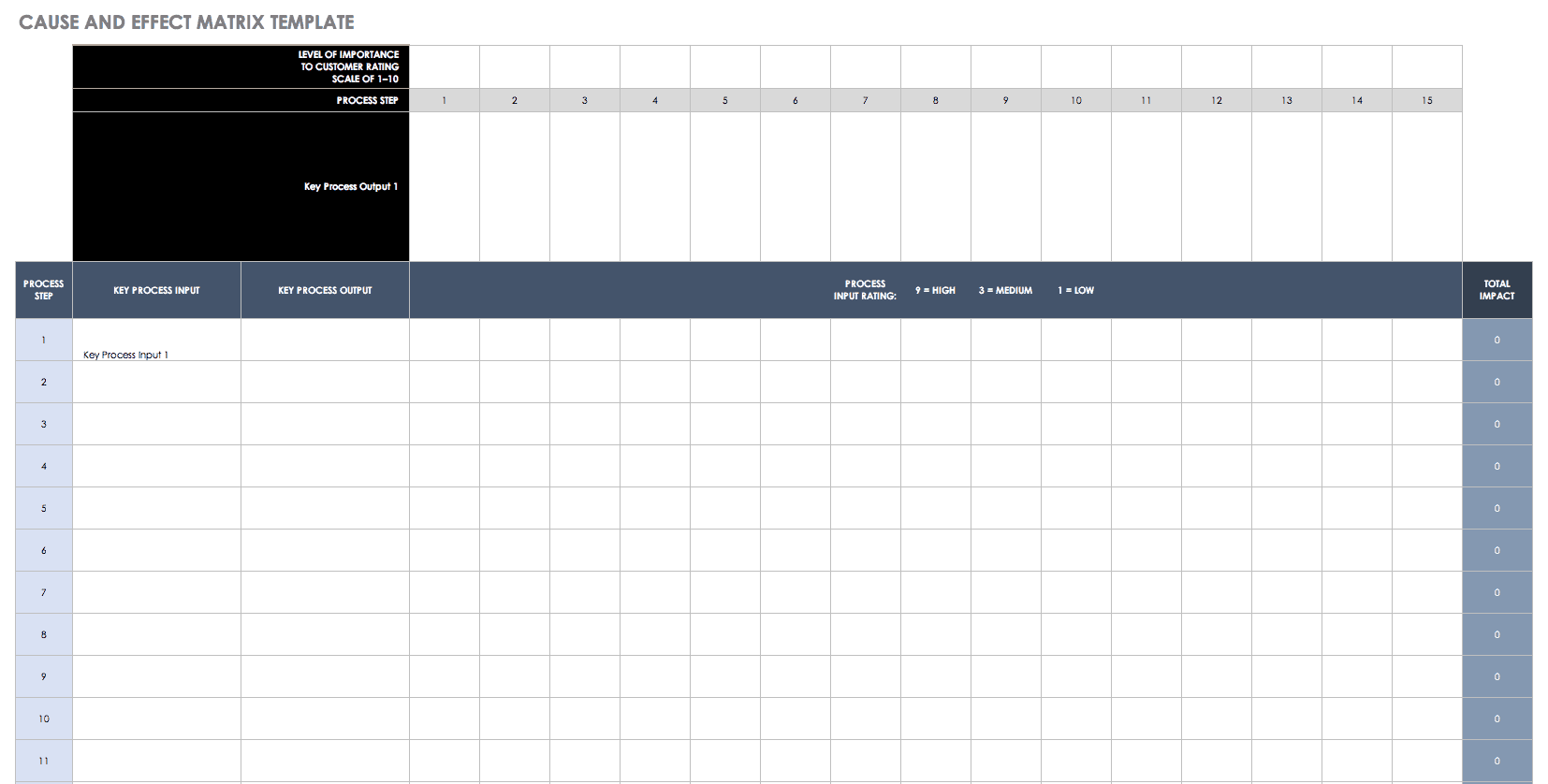

Bottom Left Corner : Support data such as Pareto Diagrams , Box Plots , Spaghetti Diagrams, Process Map , Time-Series Plot. The subjective root cause analysis usually involving a Fishbone Diagram and possible simple C&E Matrix and FMEA . Also possible use of the 5-Why methodology.

Right Side of A3 - DO / CHECK / ACT

Upper Right Corner : Action register with accountability and dates. Answer the who, what, when, where, and how.

Lower Right Corner : A measurement plan to verify the results and check them to ensure goals are met. Also a plan to sustain the gains and implement gains to other areas of the company.

A3 Template

| Download this free .zip file for an in Excel. |

Return to Lean Manufacturing

Return to DMAIC

More Templates, Tables, and Calculators

Return to the Six-Sigma-Material.com home page

- Templates + Calcs

- Training Slides

- Six Sigma Jobs

Practice Exam

- Six Sigma Courses

FULL Site Access

- Subscription

A few Member Pages

- Project Mgmt

Project Pitfalls

- Project Acceleration

- Power/Sample Size

- Hyp. Test Flowcharts

- Cost of Inventory

- Financial Savings

- Icebreakers

- Multi-Vari Study

- Fishbone Diagram

- Normalized Yield

- Spearman's Rho

- DEFINE Phase

- MEASURE Phase

- ANALYZE Phase

- IMPROVE Phase

- CONTROL Phase

- LEAN Manufacturing

Basic Statistics

- Predictive Maint.

Six Sigma Careers

- MBB Training

- BLACK BELT Training

- GREEN BELT Training

- YELLOW BELT Training

- Certifications

- Stats Software

- Quality Gurus

- Six Sigma Books

Recent Articles

Process capability indices.

Oct 18, 21 09:32 AM

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma, Six Sigma Training, Courses, Calculators, Certification

Aug 15, 21 10:27 PM

Site Membership LEARN MORE

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Cost of Quality

Process Mapping

Capability Studies

Cause & Effect Matrix

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

1-Way ANOVA

Correlation

Control Plan

MTBF and MTTR

Error Proofing

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

... and more

Need a Gantt Chart?

Copyright © 2024 Six-Sigma-Material.com. All Rights Reserved. | Privacy Policy

A3 Problem Solving Template

Subject: template.

A3 Problem Solving Excel Template

The A3 Project Report tool is ideal for systematically structuring and standardizing your problem-solving process. This free template aims to assist you in tackling workplace problems.

The A3 template is based on the A3 problem-solving method, which is a popular method for continuous improvement in Lean and Six Sigma methodologies. It walks you through a structured process of defining, analyzing, and resolving a problem, allowing you to communicate your findings and proposed solutions clearly.

The Template also includes an example of a complete A3 to use as benchmarking and as an example of how a complete A3 can look.

Learn how to conduct A3 problem solving with our in-depth A3 Problem Solving Guide .

Requirements

Training information.

Structured Approach: Based on the A3 problem-solving method, this template provides a step-by-step process for defining, analyzing, and resolving problems.

Customizable Fields: The template is fully customizable, allowing you to tailor it to your specific needs and requirements. Add or remove fields, adjust the formatting, and input your data with ease.

Root Cause Analysis: The template includes a comprehensive root cause analysis section, allowing you to gather and analyze data to identify the underlying causes of a problem.

Solution Development: The template guides you through the process of developing and evaluating possible solutions, helping you choose the most effective solution.

Implementation Plan: Once a solution has been selected, the template provides a plan for verifying its effectiveness and ensuring successful implementation.

Clear Communication: The template helps you to clearly communicate your findings and proposed solutions, making it easier for stakeholders to understand and support your efforts.

Microsoft Excel Format: The template has been developed in Microsoft Excel format, making it easy to use and accessible to a wide range of users familiar with the software.

Free to Download: Best of all, the A3 Problem Solving Excel template is completely free to download.

This template works on any recent Microsoft Excel software, including Office 365.

A full guide on how to use this template and complete A3 problem solving can be found in our guides section: A3 Problem Solving Guide.

Related Templates

5 Whys Template

5 Whys Excel Template Root Cause Analysis: The 5 Whys A powerful tool for quickly identifying and addressing the root…

Template: OEE Calculator

OEE Calculator Excel Template The OEE Calculator Excel Template is an invaluable tool designed for manufacturing professionals aiming for operational…

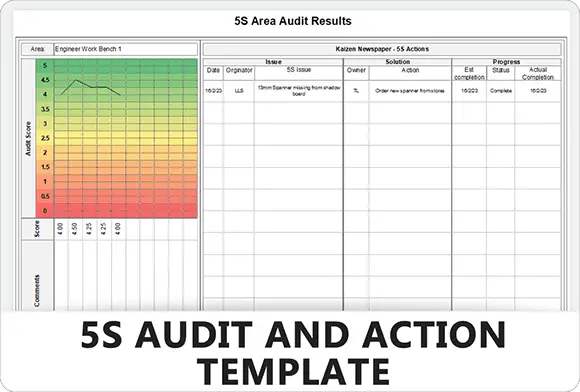

5S Audit and Action Template

5S Audit and Action Excel Template 5s Audit trend and action tracking Excel template, designed to help businesses streamline their…

Was this helpful?

Continuous Improvement Toolkit

Effective Tools for Business and Life!

A3 Thinking: A Structured Approach to Problem Solving

- 5 MINUTES READ

Also known as A3 Problem Solving.

Variants include 8D and CAPA.

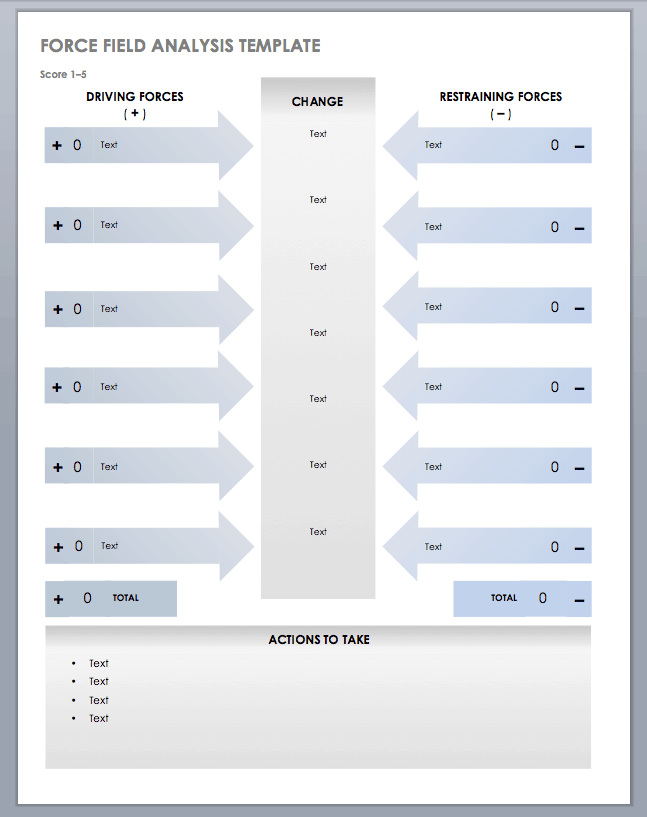

A significant part of a leader’s role involves addressing problems as they arise. Various approaches and tools are available to facilitate problem-solving which is the driving force behind continuous improvement. These methods range from the advanced and more complex methodologies like Six Sigma to the simpler and more straightforward A3 thinking approach.

The power of the A3 approach lies in its systematic and structured approach to problem-solving. Although it appears to be a step-by-step process, A3 is built around the PDCA philosophy. It relies on the principle that it is much better to address the real root-cause rather than trying to find a solution. Hence, it’s important not to jump to the solution when solving a problem as it is likely to be less effective.

A3 thinking provides an effective way to bring together many of the problem-solving tools into one place. For example, techniques such as the 5 Whys and fishbone analysis can be used during the ‘Analysis’ stage to help identifying the root causes. Additionally, visual aids and graphs are highly recommended in the A3 report, as they are more effective than text in communicating ideas and providing concise project updates.

A3 thinking involves the practice of consolidating the problem, analysis, countermeasures, and action plan onto a single sheet of paper, commonly an A3-sized sheet. This brief document serves as a summary of the project at hand and is regarded as a valuable storytelling tool for project communication. Utilizing the A3 approach doesn’t require any specialized software or advanced computer skills. You may however use readily available A3 templates , or rely on basic tools such as paper, pencil and an eraser as you will need to erase and rewrite several times.

One of the characteristics of the A3 approach is that it does not get into specific details. Detailed documents are usually attached to the A3 report to prevent overwhelming the reader with an excess of information.

The A3 process is typically structured in multiple stages based on the PDCA model. The primary focus is on developing understanding of the current situation and defining the desired outcome before thinking about the solution. While the exact number of stages may vary depending on the preference of the company, what truly matters is adhering to a structured approach to problem-solving.

A3 Seven Stages Model

An A3 process is often managed by an individual who should own and maintain the A3 report. This individual takes the lead in steering the process, facilitating team involvement, and preparing the A3 report with team input. One of the most common models for A3 thinking is the seven stages model which is described in the following.

1. Background – The first step is to identify the business reason for choosing this problem or opportunity. In this stage, you need to identify the gap in performance and the extent of the problem.

2. Current situation – The purpose of this stage is to document the current state of the problem. You may need to refer to the process map or go to the Gemba to truly understand the current situation.

3. Target – The purpose of this stage is to define the desired future state. Clearly identify the expected benefits from solving the problem, the scope, and the key metrics that will help measure the success of the project.

4. Analysis – The objective of this stage is to conduct an in-depth analysis of the problem and understand why it’s happening. It might involve tools like the 5 Whys and cause-and-effect analysis, as well as advanced statistical methods.

5. Countermeasures – Countermeasures are the actions to be taken to eliminate root causes or reduce their effects. The team should brainstorm and evaluate possible countermeasures based on the analysis conducted earlier.

6. Implementation Plan – To achieve the target, develop a workable plan to implement the countermeasures. Gantt charts are great ways to manage implementation plans very simply and easily. Once the action plan is finalized, the team should begin working on the activities needed to implement the countermeasures.

7. Follow-up – The final stage involves evaluating the implementation of the plan and the results achieved. Follow-up actions are important to ensure the benefits extend beyond the project’s completion.

A3 thinking is considered to be the practical form of the PDCA model.

There are many online templates that can be used to manage your problem-solving efforts. One of the simplest and most straightforward ways is to use this A3 problem solving template .

Wrapping Up

A3 thinking represents a logical and structured approach for problem solving and continuous improvement. This approach can be used for most kinds of problems and in any part of the business. Originating from the Toyota Production System (TPS), it has been adopted by many Lean organizations around the world.

A3 thinking not only provides a systematic approach for problem-solving. The development of a continuous improvement culture is at the core of A3 thinking. It has become one of the most popular Lean tools today where people and teams work together to solve problems, share results and learn from each other.

Other Formats

Do you want to use the slides in your training courses?

A3 Thinking Training Material – $18.85

Related Articles

Project Charter

Gantt Chart

Related Templates

A3 Problem Solving

Written by:

CIToolkit Content Team

Free Lean Six Sigma Templates

By Kate Eby | June 12, 2017

- Share on Facebook

- Share on LinkedIn

Link copied

Lean Six Sigma combines two methods that streamline business processes in order to reduce waste, improve quality, and increase efficiency and product value. Both approaches originated in the manufacturing industry - Lean by Toyota and Six Sigma by Motorola - but today they are used to improve many processes within an organization, from customer support to administration. The templates provided here are suitable for Yellow, Green, and Black Belts. You’ll find Six Sigma project templates designed to support the different phases of an improvement process, all of which are free to download. Simply click on the link to download and open a template file, and customize it to suit your needs.

Six Sigma Tools

Six Sigma is a quality measurement that represents 3.4 Defects Per Million Opportunities. That’s a lofty goal for many business processes, but you can use Six Sigma methods to improve quality and performance in varying degrees based on the needs and objectives of a business or project. Six Sigma tools range from statistical charts, illustrative diagrams, and data collection methods to project management and process analyzation worksheets. These tools may not be exclusive to Six Sigma, but they can be applied in specific ways to focus on process improvement. The tools required depend on the project requirements and team roles. Depending on one’s training and experience, a Six Sigma professional may be involved in improvement initiatives at the White, Yellow, Green, or Black Belt level. White Belts generally have supporting roles, while Yellow Belts act as team members, Green Belts collect and analyze data, and Black Belts serve as project leaders. In the following sections, you’ll find a number of free, downloadable templates that you can use as Six Sigma tools.

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

View the guide

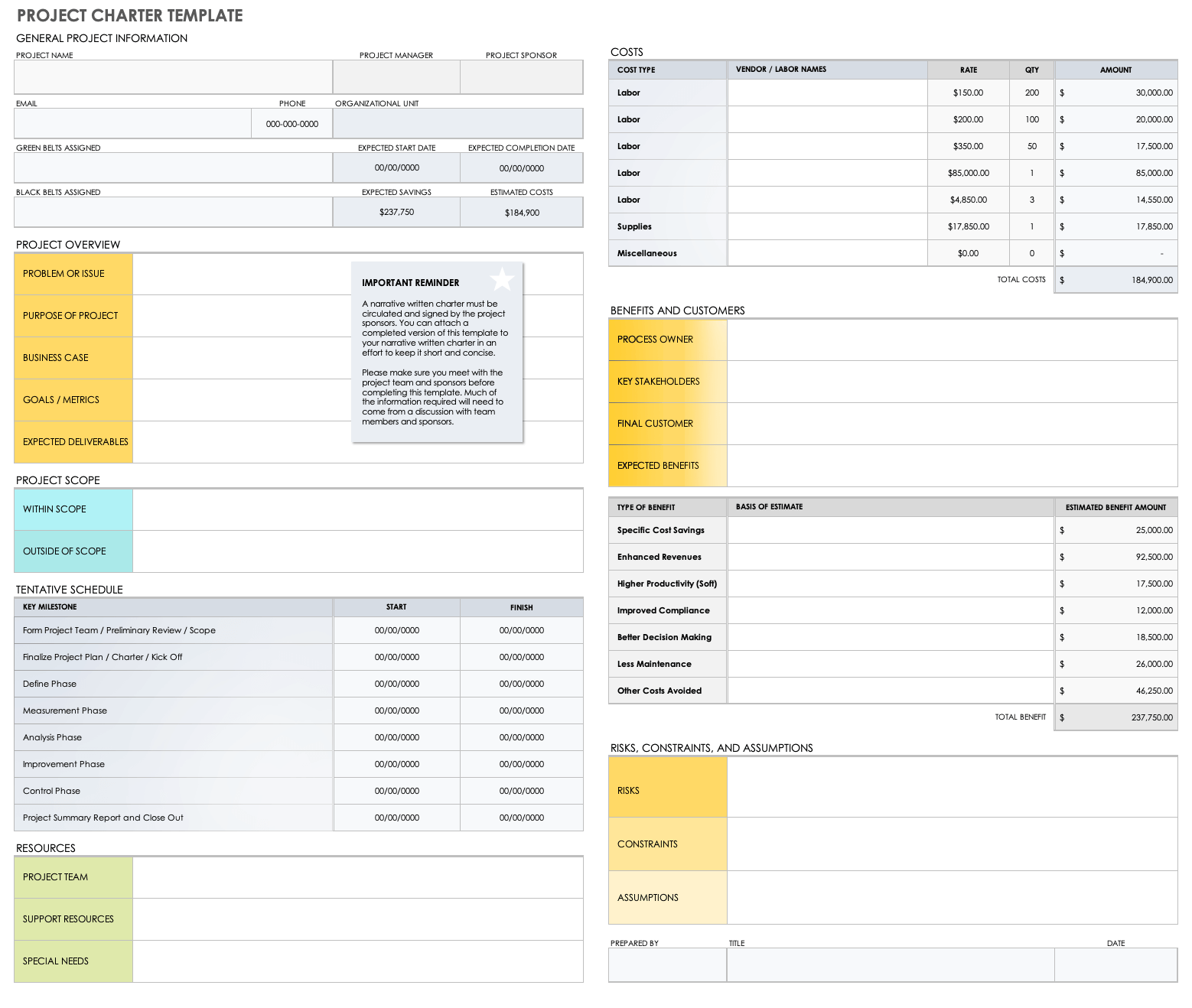

Project Charter Template

This Six Sigma Excel template is designed to help you create a project charter that will serve as an agreement between management and your team. A project charter provides an overview of a project including team roles and responsibilities, financial information, goals, and constraints. Creating a detailed project charter will help define your project and its expected outcome, and provide a high-level roadmap to follow.

Download Project Charter Template

Excel | Word | Smartsheet

Implementation Plan Template

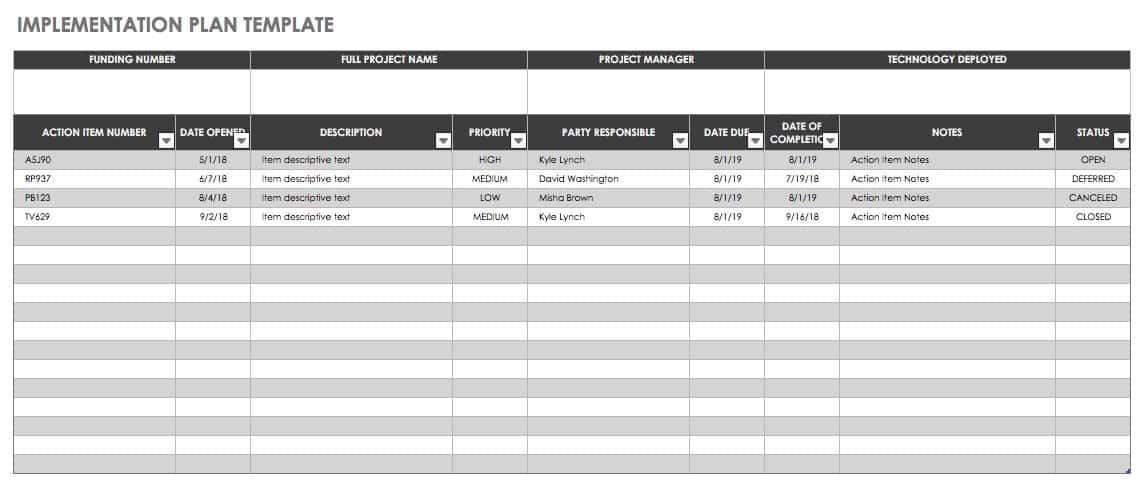

It’s important to refer to previous research and planning to help create an effective action plan. Once you know what actions to take, this implementation plan template helps you organize them by priority, assign ownership, track progress, and update the plan as needed. This is an important Six Sigma tool for taking concrete actions toward achieving measurable objectives.

Download Implementation Plan Template

Excel | Smartsheet

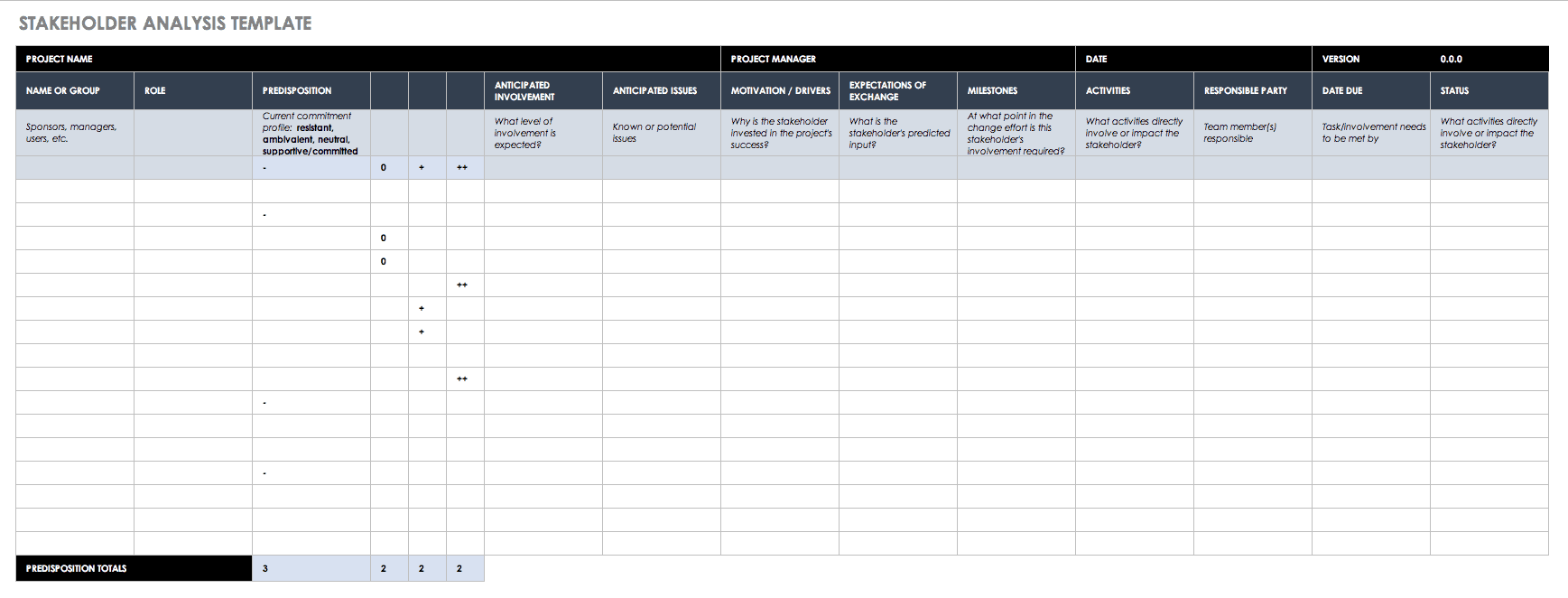

Stakeholder Analysis Template

You can use this template to identify and analyze stakeholders in order to enlist support for a project. The template allows you to closely examine important factors such as issues that may be influencing stakeholders, their vested interest in a project, or the level of influence and support. Understanding the views and expectations of stakeholders can help you anticipate and address issues in advance and move your project toward success.

Download Stakeholder Analysis Template

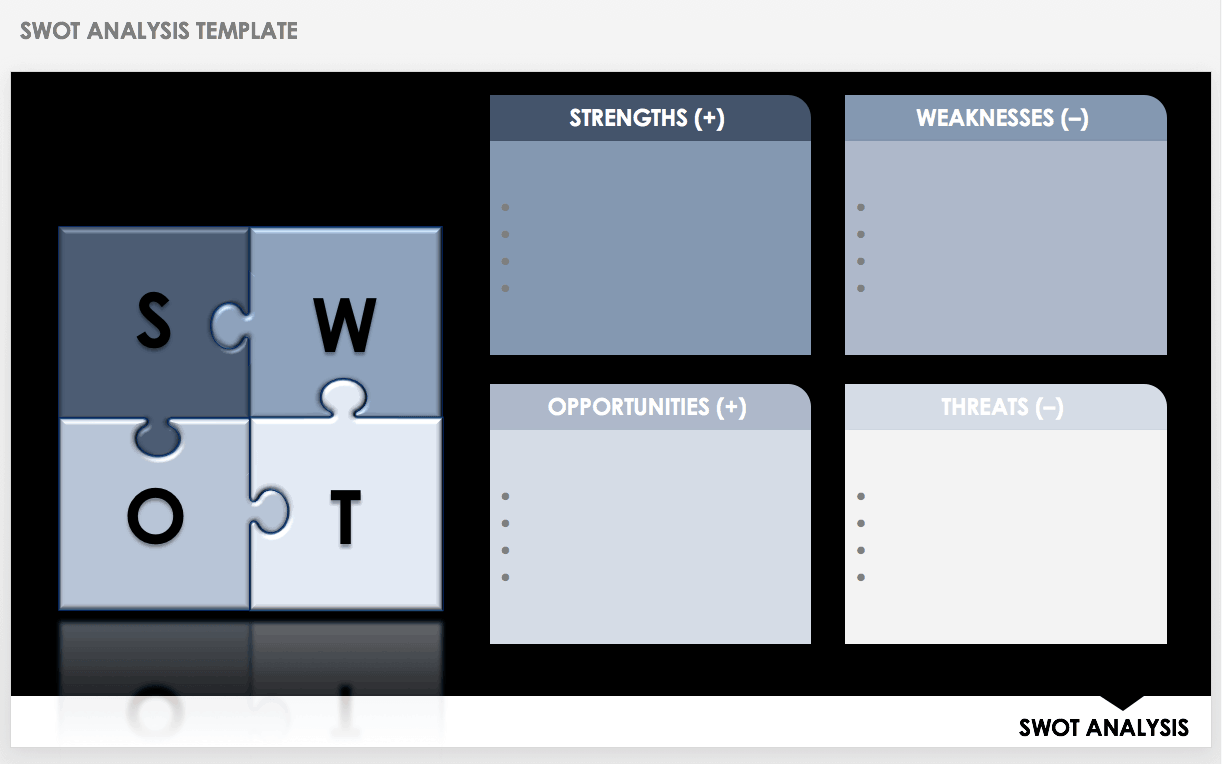

SWOT Analysis Template

Use this SWOT analysis template for strategic planning and to create dynamic PowerPoint presentations. List the strengths, weaknesses, opportunities, and threats related to an idea, process, or organization, and use this information for strategic analysis. Easily add this PowerPoint slide to any presentation for visual communication with project team members or other stakeholders.

Download SWOT Analysis Template - PPT

PPT | Smartsheet

Fishbone Diagram Template

A fishbone diagram, also known as a cause and effect diagram or Ishikawa diagram, helps teams brainstorm the causes of a certain event. Use this Six Sigma tool along with the 5 Whys template to determine root causes. One of the benefits of using a fishbone diagram is the visual layout, which makes it easy to compile and view information, and see the relationships between different elements.

Download Fishbone Diagram Template - Excel

A3 Template

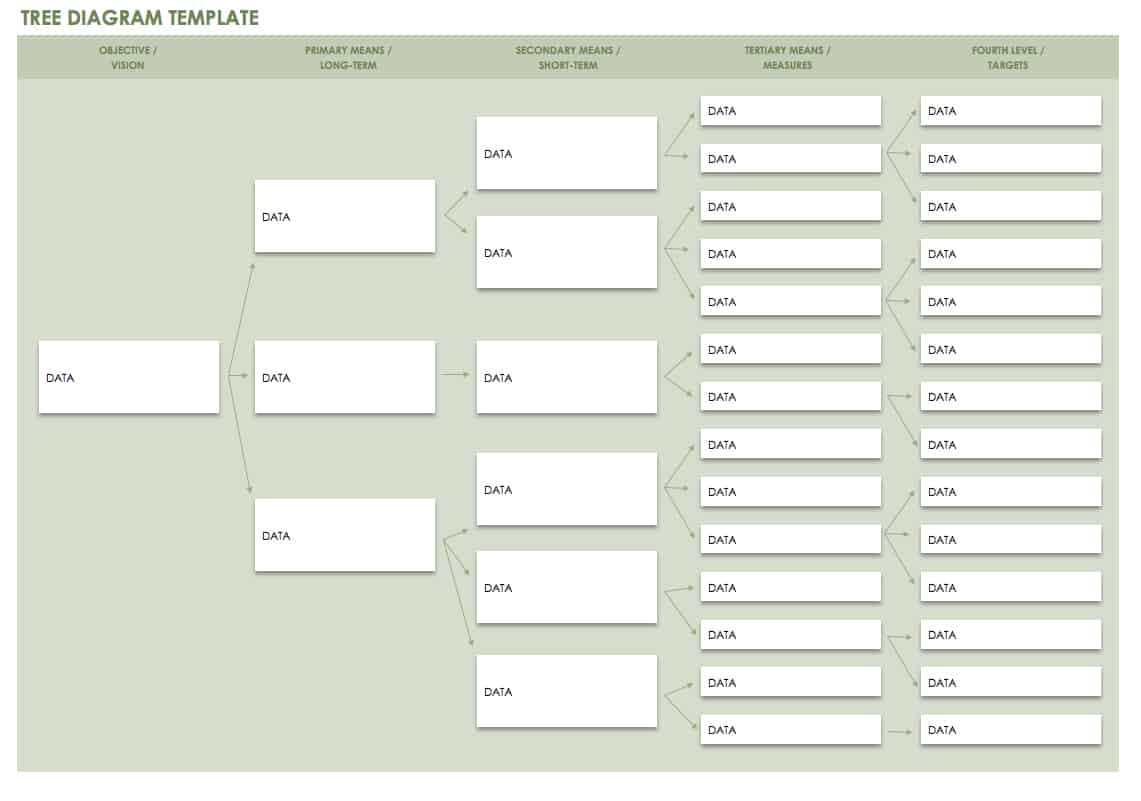

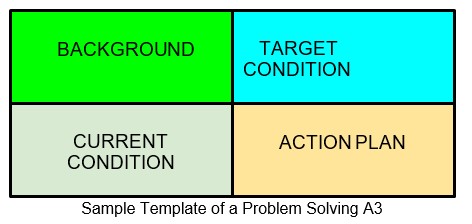

A3 is an approach to problem solving that grew out of Lean Manufacturing at Toyota. The A3 report condenses project information onto a single page in an easy-to-read, graphical format. This A3 template provides sections for describing background information, current conditions, root cause analysis, target conditions, implementation plan, and follow-up.

Download A3 Template - Excel

5 Whys Template

A 5 Whys worksheet can help you undertake a root cause analysis to determine the sources of defects or performance issues. After defining the problem, you ask five questions to drill down into why the problem is happening, and track the issue back to its root cause. The final step is to determine what action you should take to eliminate that root cause.

Download 5 Whys Template

Excel | Word | PDF

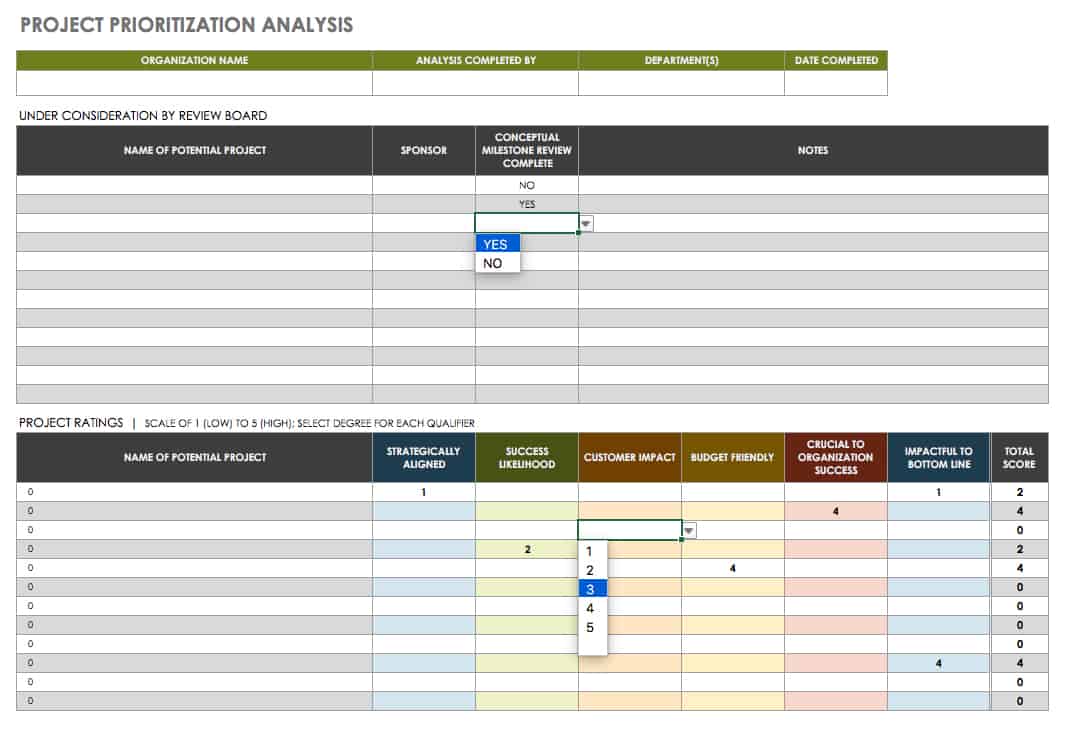

Project Prioritization Analysis